Environment-friendly recycling method for abandoned cathode carbon blocks of aluminum electrolysis cell

A cathode carbon block and aluminum electrolytic cell technology, which is applied in the field of recycling and environmental protection of waste cathode carbon blocks in aluminum electrolytic cells, can solve the problems such as failure to form an industrial-scale treatment degree, high production cost, and failure to recover, and achieves direct The indirect economic and environmental benefits are obvious, and the technology is simple and practical.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

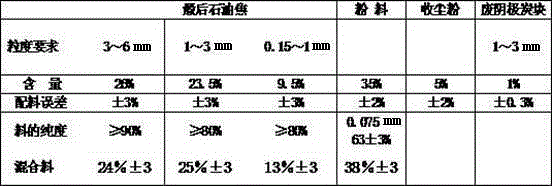

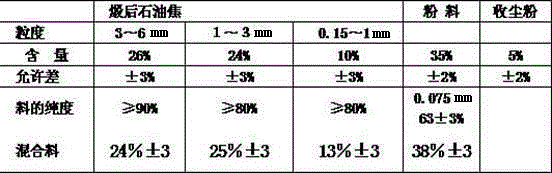

[0025] The general production process of carbon anode used in the electrolytic aluminum industry is to calcine petroleum coke at high temperature to remove ash impurities, crush it, knead it with asphalt according to different particle size ratios, and roast it at high temperature to form an excellent carbon conductor with a carbon content of 99.5%.

[0026] The content of the present invention is to break the discarded cathode carbon blocks according to the particle size requirements of carbon production for electrolytic aluminum, and mix them into the aluminum electrolytic carbon anode production system according to a certain proportion, so that the carbon components can be converted into useful components of carbon anodes. However, many changes in the carbon production process make the fluoride salt in the spent cathode carbon block enter the anode carbon body for electrolytic aluminum, turning waste into treasure in the production of aluminum electrolytic cells.

[0027] To...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com