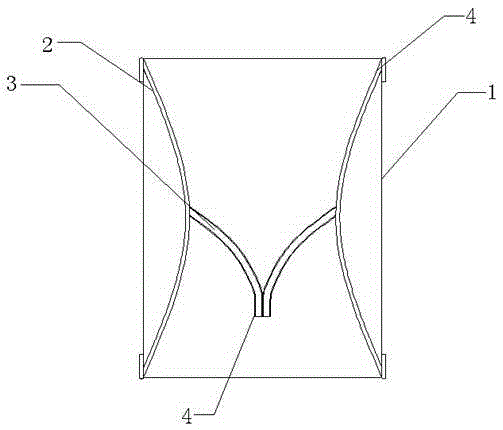

Material opening sealing device

A technology of sealing device and feed port, which is applied in the field of mining machinery, can solve problems affecting the operation and health of workers, mixed dust, energy waste, etc., to improve mechanical properties and mechanical properties, prolong service life, and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The valve material is a material made by blending silicone rubber and polyurethane, and the blended material is made of the following components according to the component ratio: 60 parts of methyl vinyl silicone rubber raw rubber, 50 parts of white carbon black, 110 parts of polyurethane 13 parts of hexamethyldisilazane, 2 parts of diphenylsilanediol, 0.6 parts of platinum catalyst, 1.4 parts of hydrogen-containing silicone oil, 3 parts of compatibilizer A, and 5 parts of compatibilizer B.

[0034] The molar fraction of vinyl in the methyl vinyl silicone rubber raw rubber is 1.37%, and the white carbon black is prepared by the gas phase method, and the specific surface area is 170m 2 / g, the hydrogen-containing silicone oil is a high hydrogen-containing silicone oil, and the platinum catalyst is a divinyltetramethyldisiloxane complex prepared by the reaction of chloroplatinic acid and divinyltetramethyldisiloxane Catalyst, the compatibilizer A is made from 100 parts of...

Embodiment 2

[0043] The valve material is a material made by blending silicone rubber and polyurethane, and the blended material is made of the following components according to the component ratio: 50 parts of methyl vinyl silicone rubber raw rubber, 40 parts of white carbon black, 80 parts of polyurethane 12 parts of hexamethyldisilazane, 1 part of diphenylsilanediol, 0.5 parts of platinum catalyst, 1.2 parts of hydrogen-containing silicone oil, 2 parts of compatibilizer A, and 3 parts of compatibilizer B.

[0044] The molar fraction of vinyl in the methyl vinyl silicone rubber raw rubber is 1.37%, and the white carbon black is prepared by the gas phase method, and the specific surface area is 160m 2 / g, the hydrogen-containing silicone oil is a high hydrogen-containing silicone oil, and the platinum catalyst is a divinyltetramethyldisiloxane complex prepared by the reaction of chloroplatinic acid and divinyltetramethyldisiloxane Catalyst, the compatibilizer A is made from 100 parts of e...

Embodiment 3

[0053] The valve material is a material made by blending silicone rubber and polyurethane, and the blended material is made of the following components according to the component ratio: 70 parts of methyl vinyl silicone rubber raw rubber, 57 parts of white carbon black, 120 parts of polyurethane 21 parts of hexamethyldisilazane, 5 parts of diphenylsilanediol, 2 parts of platinum catalyst, 1.7 parts of hydrogen-containing silicone oil, 5 parts of compatibilizer A, and 2 parts of compatibilizer B.

[0054] The molar fraction of vinyl in the methyl vinyl silicone rubber raw rubber is 1.37%, and the white carbon black is prepared by the gas phase method, and the specific surface area is 180m 2 / g, the hydrogen-containing silicone oil is a high hydrogen-containing silicone oil, and the platinum catalyst is a divinyltetramethyldisiloxane complex prepared by the reaction of chloroplatinic acid and divinyltetramethyldisiloxane Catalyst, the compatibilizer A is made from 100 parts of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com