Secondary Battery

A secondary battery and electrolyte technology, applied in secondary batteries, secondary battery manufacturing, secondary battery parts, etc., can solve problems such as electrolyte decomposition, battery damage to battery safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1-1 to 1-9-6

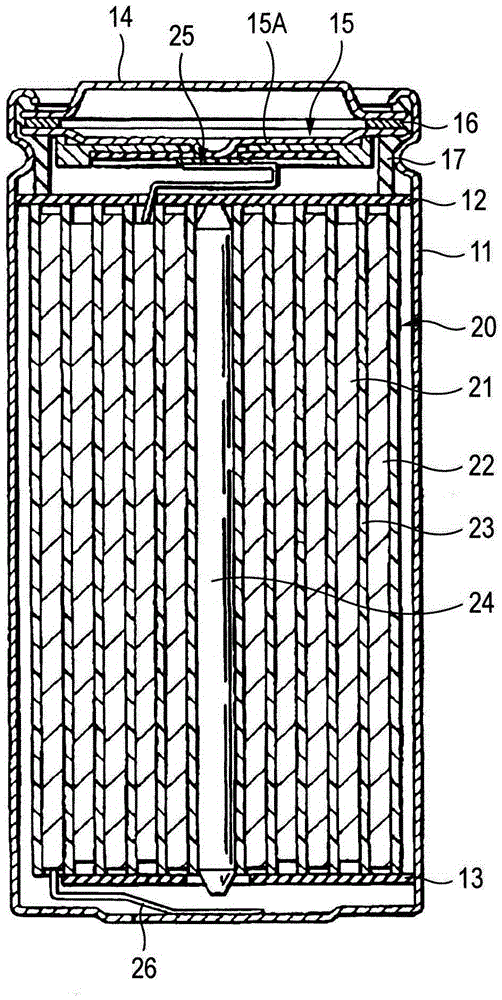

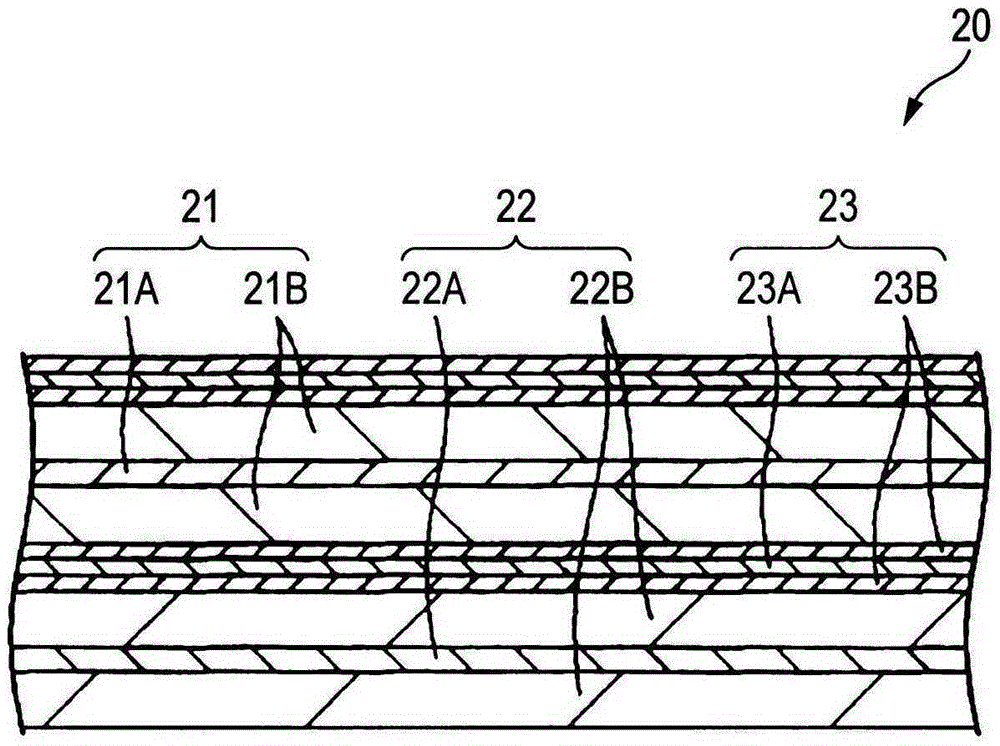

[0131] In Examples 1-1-1 to 1-4-6, 100% of LiCoO was used in the positive electrode 2 As a lithium composite oxide; use a polypropylene / polyethylene / polypropylene three-layer separator (PP / PE / PP three-layer separator) as a separator; and add additives as shown in Table 1 to the electrolyte. The upper limit charging voltage is set at 4.25 to 4.60V.

[0132] In Examples 1-5-1 to 1-8-6, secondary batteries were prepared in the same manner as in Examples 1-1-1 to 1-4-6 except that a polyethylene separator (PE separator sheet) as a spacer.

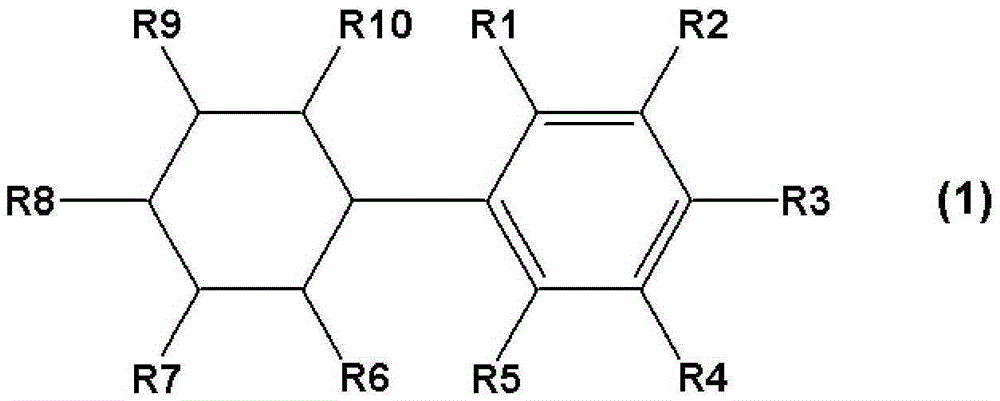

[0133] In Examples 1-9-1 to 1-9-6, secondary batteries were produced in the same manner as in Examples 1-1-1 to 1-4-6 except that cyclohexylbenzene was used as an additive.

Embodiment 2-1-1 to 2-1-8

[0148] Secondary batteries were prepared in the same manner as in Example 1-5-3 and Example 1-7-3 except that the separator used was changed to those shown in Table 2 below. The results obtained by evaluating the characteristics of the respective secondary batteries of Examples 2-1-1 to 2-1-8 are shown in Table 2 below.

[0149] Table 2

[0150]

[0151] It can be found from Table 2 that PP-blended PE separator, PTFE / PE / PTFE separator, Al 2 o 3 - Coated PE separator, or SiO 2 -In all of the examples 2-1-1 to 2-1-8 of the PE release sheet of the coating, compared with the example 1-5-3 and the example 1-7-3 using the PE release sheet, it shows Excellent continuous charging characteristics. Also, other properties are equivalent.

[0152] Also, referring to Table 1, in a battery in which a PE separator is used and 1-cyclohexyl-2-fluorobenzene or 1-cyclohexyl-4-fluorobenzene is added, in the case where charging is performed while controlling the upper limit voltage to 4.20...

Embodiment 3-1-1 to 3-3-5

[0155] Secondary batteries were prepared in the same manner as in Example 1-1-3, except that the amounts and kinds of additives added to the electrolytic solution were changed as shown in Table 3 below. The results obtained by evaluating the characteristics of each of the secondary batteries of Examples 3-1-1 to 3-3-5 are shown in Table 3 below.

[0156] table 3

[0157]

[0158] From Table 3, it can be found that in all the examples in which the amount of 1-cyclohexyl-2-fluorobenzene or 1-cyclohexyl-4-fluorobenzene added to the electrolytic solution was in the range of 0.1 to 20% by mass In 3-1-1 to 3-2-5, compared with Comparative Example 1-5-3 in which no additive was added, satisfactory results could be obtained. Furthermore, it was found that in Examples 3-3-1 to 3-3-5 in which equal amounts of 1-cyclohexyl-2-fluorobenzene and 1-cyclohexyl-4-fluorobenzene were added to the electrolytic solution, When the concentration of each of these additives in the electrolyte fal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com