Hot-pressed part and its manufacturing method

A manufacturing method and technology for parts, applied in the plating, coating, metal material coating process of superimposed layers, etc., can solve the problems of surface damage of parts, mold damage, insufficient corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

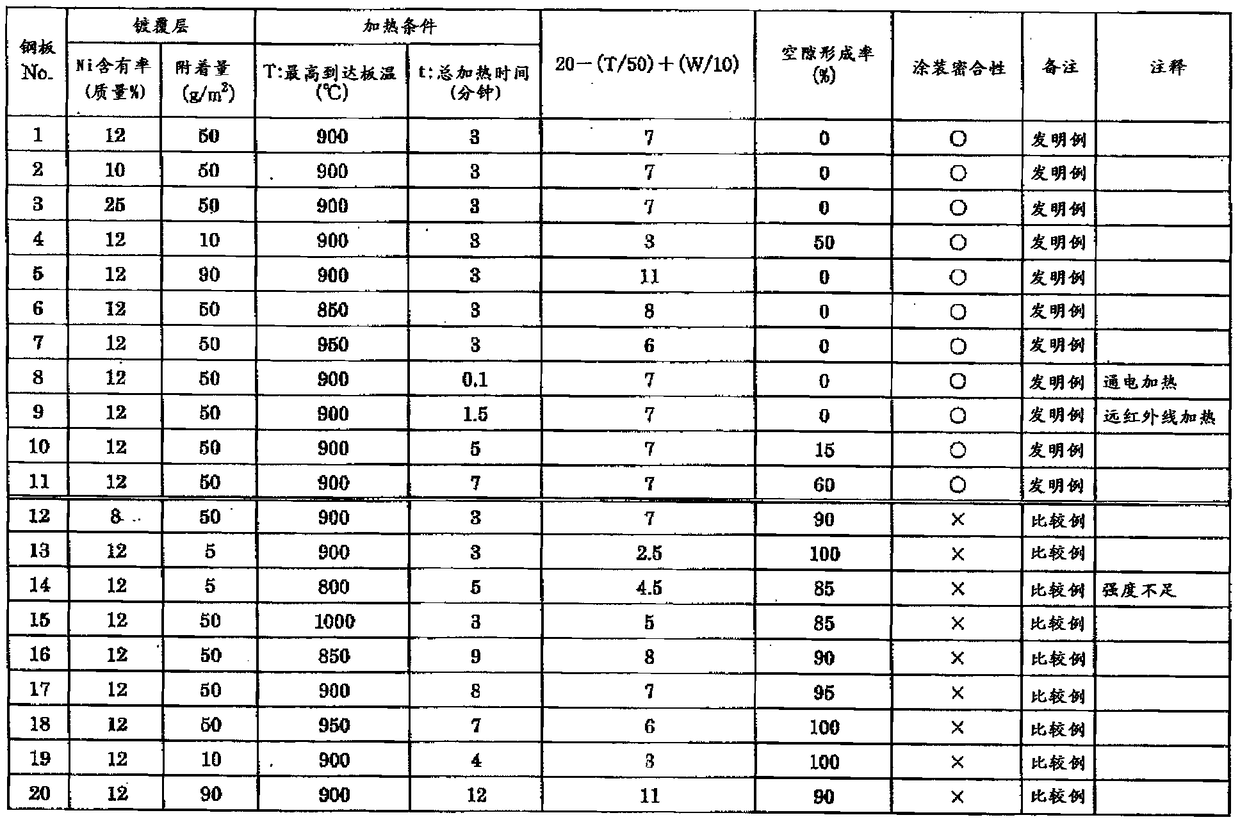

[0076] As the base steel sheet, a steel sheet containing C: 0.23%, Si: 0.25%, Mn: 1.2%, P: 0.01%, S: 0.01%, Al: 0.03%, N: 0.005%, and Cr: 0.2% was used in mass %. , Ti: 0.02%, B: 0.0022%, Sb: 0.008%, and the remainder is composed of Fe and unavoidable impurities, Ac 3 A cold-rolled steel sheet with a transformation point of 820°C and a thickness of 1.6 mm. The surface of this cold-rolled steel sheet was plated with Zn-Ni by an electroplating method, and steel sheet No. 1-20 were produced. Zn-Ni plating is carried out in a plating bath containing 200g / L of nickel sulfate hexahydrate and 10-100g / L of zinc sulfate heptahydrate with a pH of 1.5 and a bath temperature of 50°C. The current density is set to 5 ~100A / dm 2 Plating is performed. The Ni content was adjusted by changing the amount of zinc sulfate heptahydrate added and the current density. In addition, by changing the energization time, the plating deposition amount was adjusted.

[0077] The steel plates Nos. 1 to 2...

Embodiment 2

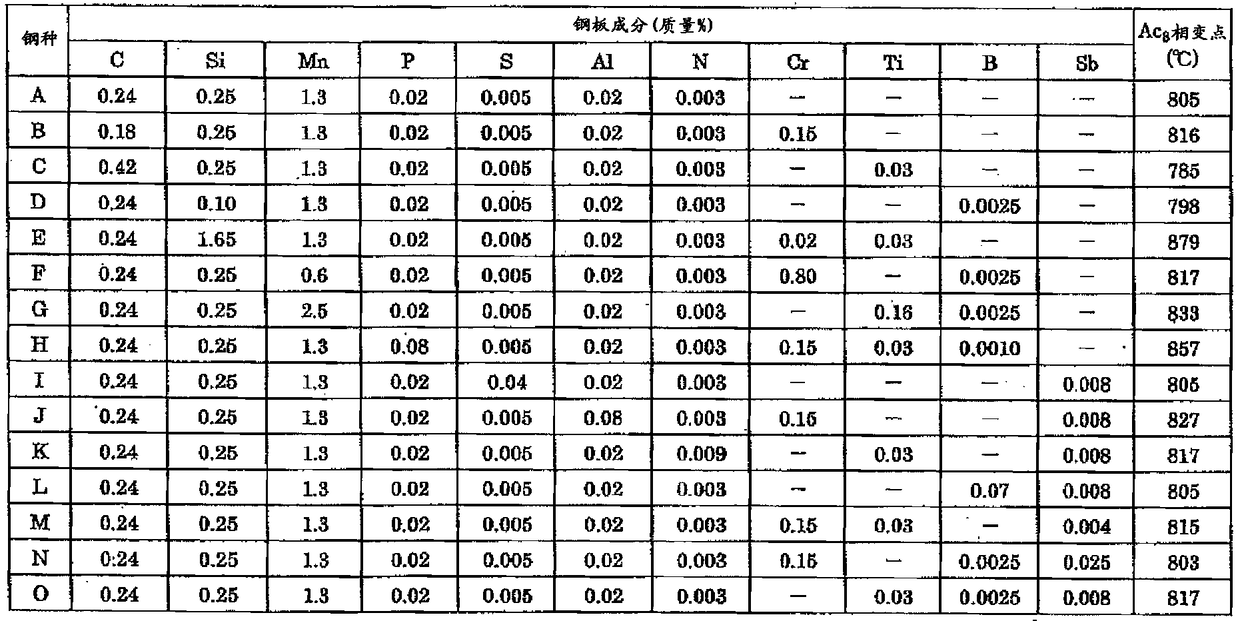

[0088] As the base steel sheet, a steel sheet containing the composition shown in Table 2, the remainder consisting of Fe and unavoidable impurities, and having Ac shown in Table 2 was used. 3 The plate thickness at the transformation point is a cold-rolled steel plate of 1.6 mm. Zn—Ni plating was performed on both surfaces of the cold-rolled steel sheet in the same manner as in Example 1, and steel sheet Nos. 21 to 35 having the Ni content and plating deposition amount shown in Table 3 were produced.

[0089] The steel plates No. 21 to 35 produced in this way were heated in an electric furnace so that the maximum attained plate temperature and the total heating time shown in Table 3 were obtained, and after the heating for a predetermined time was completed, they were immediately clamped with flat dies made of Al. , for quenching.

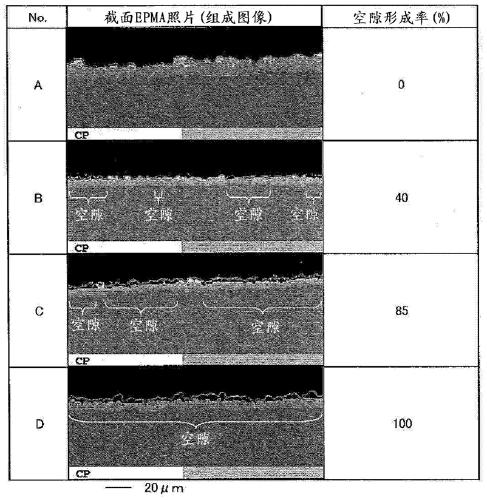

[0090] About the produced sample, the measurement of the void formation rate and the evaluation of coating adhesiveness were performed similarly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com