Metal surface treatment agent for galvanized steel, coating method and coated steel

A metal surface treatment, steel technology, applied in the direction of metal material coating technology, metal layered products, chemical instruments and methods, etc., can solve the problems of insufficient alkali resistance and achieve the effect of improving the oil resistance of pressure machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

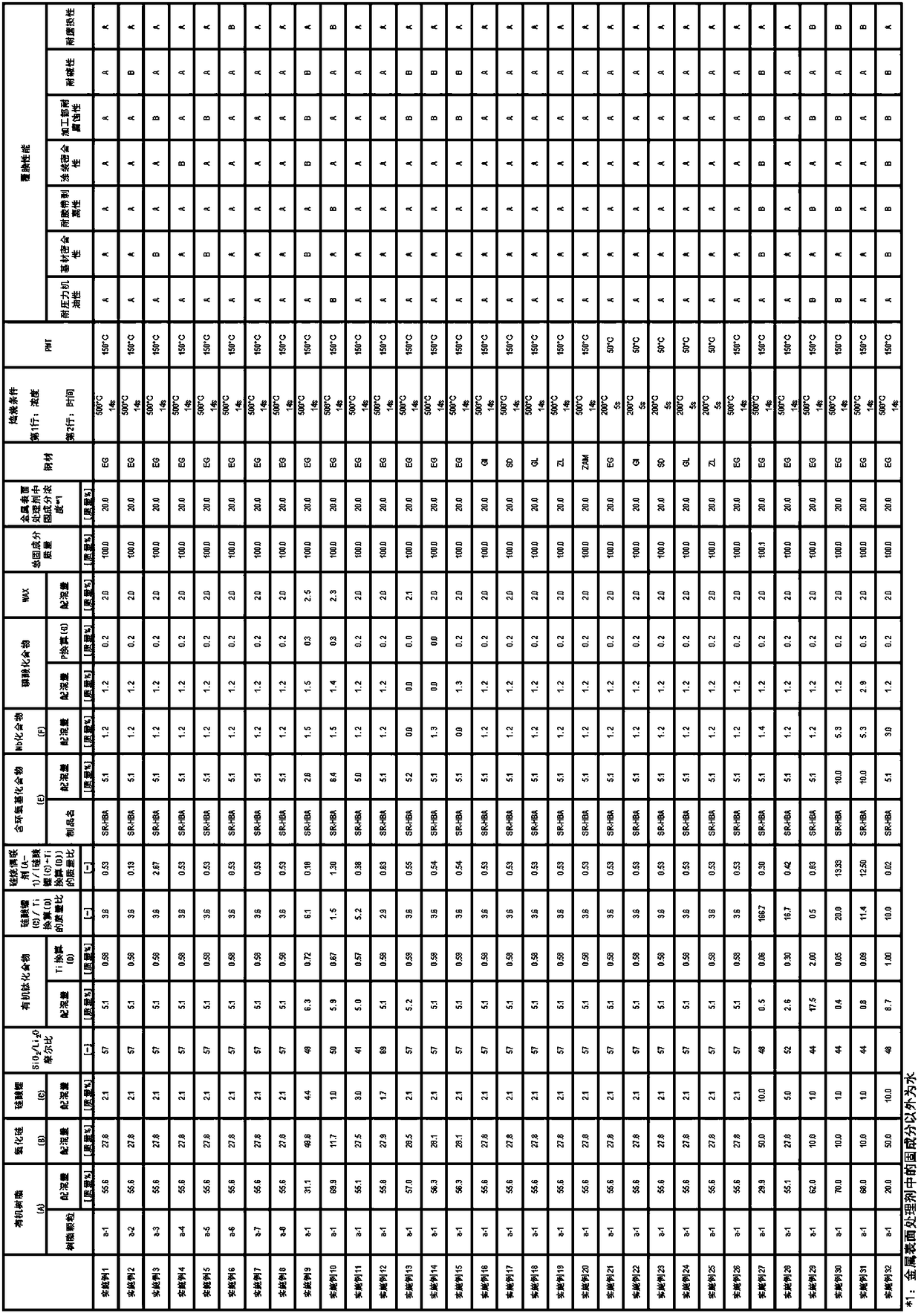

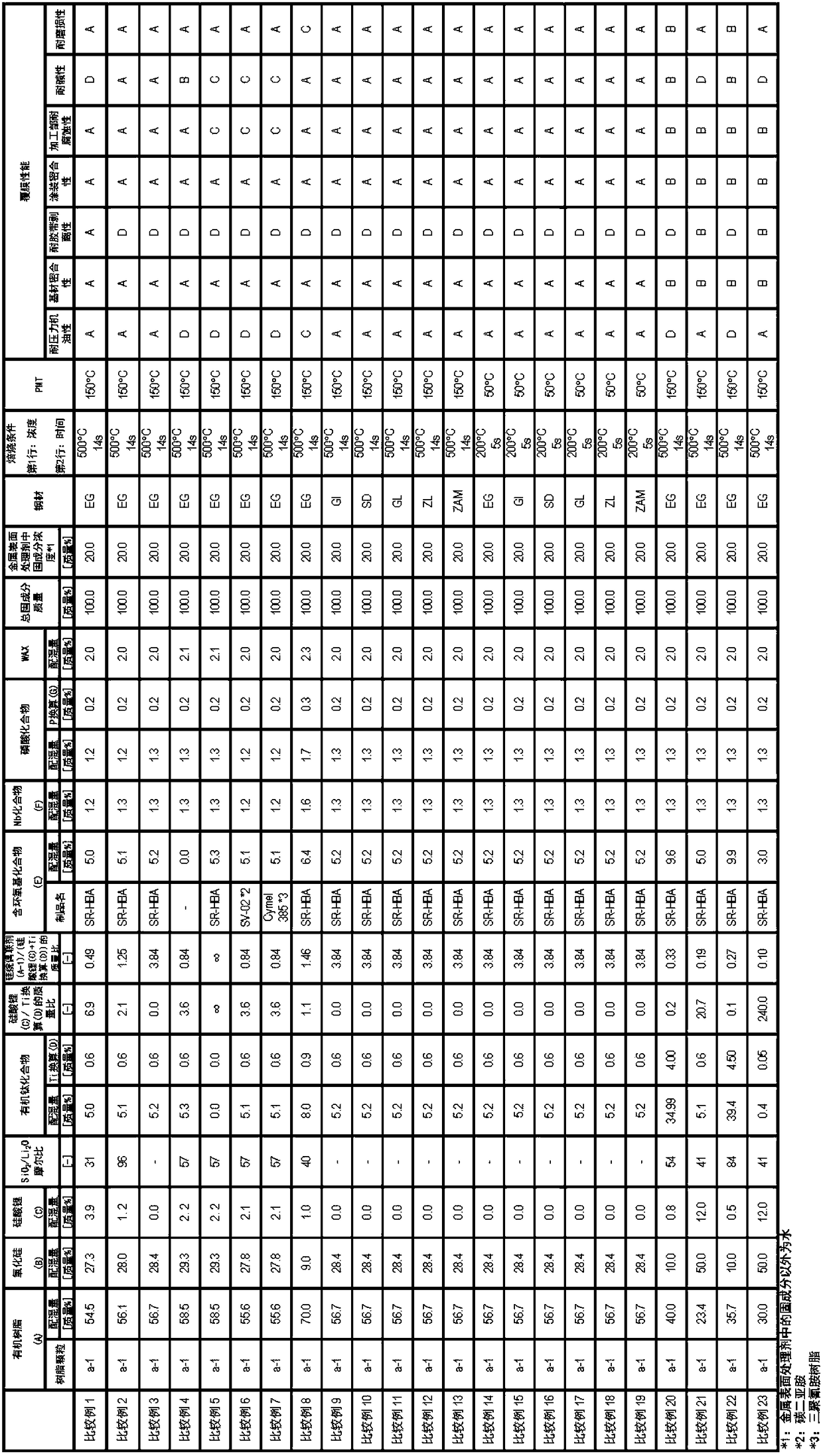

Examples

manufacture example 1

[0117] (Manufacture of resin pellets (a-1))

[0118] Add ethylene-methacrylic acid copolymer resin (80% ethylene content, 20% methacrylic acid content), 5.6% sodium hydroxide and deionized water to the reaction vessel, and stir at 95°C for 6 hours , thereby obtaining a water-dispersed resin solution with a solid content of 23%. To this water-dispersed resin solution, 0.69% of hydrogenated bisphenol A diglycidyl ether (product name: SR-HBA, manufactured by Sakamoto Pharmaceutical Co., Ltd.) and 2-(3,4-epoxycyclohexyl)ethyltrimethyl ether were further added. Oxysilane (product name: KBM-303, manufactured by Shin-Etsu Chemical Co., Ltd.) 1.15%, reacted at 85°C for 2 hours to obtain a silanol group and / or methoxysilyl group with a solid content of 24%. Aqueous dispersion of resin particles (a-1). The average particle diameter of the resin particle (a-1) measured by the particle diameter measuring apparatus FPAR-1000 (made by Otsuka Electronics Co., Ltd.) of the dynamic light sca...

manufacture example 2

[0120] (Manufacture of resin pellets (a-2))

[0121] Add ethylene-methacrylic acid copolymer resin (80% ethylene content, 20% methacrylic acid content), 5.6% sodium hydroxide and deionized water to the reaction vessel, and stir at 95°C for 6 hours , thereby obtaining a water-dispersed resin solution with a solid content of 23%. 0.69% of hydrogenated bisphenol A diglycidyl ether and 0.29% of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane were further added to the water-dispersed resin liquid, and reacted at 85° C. for 2 hours, thereby An aqueous dispersion of resin particles (a-2) having a solid content of 24% and having a silanol group and / or a methoxysilyl group was obtained. The average particle diameter of the resin particle (a-2) measured by the particle diameter measuring apparatus FPAR-1000 (made by Otsuka Electronics Co., Ltd.) of the dynamic light scattering method was 70 nm.

manufacture example 3

[0123] (Manufacture of resin pellets (a-3))

[0124] Add ethylene-methacrylic acid copolymer resin (80% ethylene content, 20% methacrylic acid content), 5.6% sodium hydroxide and deionized water to the reaction vessel, and stir at 95°C for 6 hours , thereby obtaining a water-dispersed resin solution with a solid content of 23%. 0.69% of hydrogenated bisphenol A diglycidyl ether and 5.75% of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane were further added to the water-dispersed resin liquid, and reacted at 85° C. for 2 hours, thereby An aqueous dispersion of resin particles (a-3) having a solid content of 24% and having a silanol group and / or a methoxysilyl group was obtained. The average particle diameter of the resin particle (a-3) measured by the particle diameter measuring apparatus FPAR-1000 (made by Otsuka Electronics Co., Ltd.) of the dynamic light scattering method was 70 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com