Efficient high-quality sow feed and processing method thereof

A technology of sow feed and processing method, applied in animal feed, animal feed, food processing and other directions, can solve problems affecting feed utilization, feed pollution, ingredient destruction, etc. Additive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

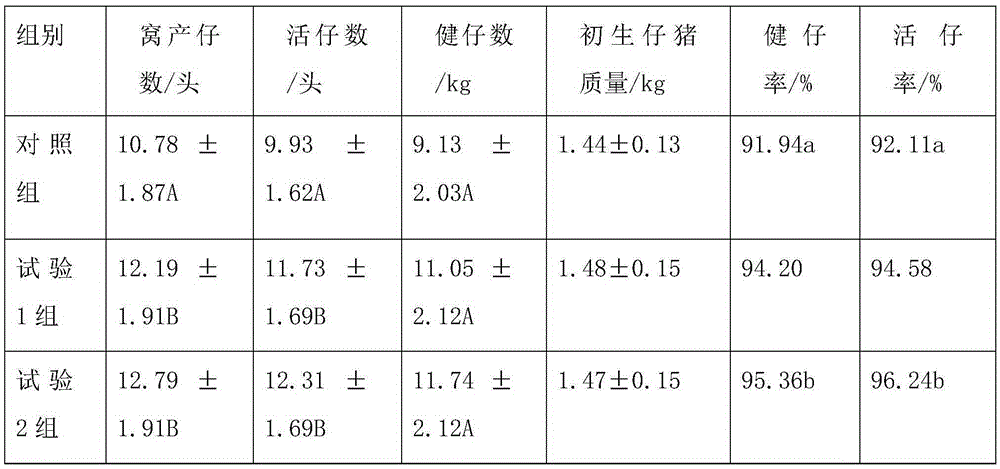

Examples

Embodiment 1

[0018] A processing method of high-efficiency and high-quality sow feed. First, the energy raw materials, protein raw materials, and high-temperature-resistant raw materials with large particle sizes and large quantities are crushed, proportioned, and mixed, and then the first high-temperature granulation and aging are carried out; , and then finely pulverize the feed pellets, then mix and proportion the heat-sensitive raw materials in the feed formula, and then carry out the second low-temperature pelleting after mixing; after cooling, the finished product is packaged.

Embodiment 2

[0020] A processing method of high-efficiency and high-quality sow feed. First, the energy raw materials, protein raw materials, and high-temperature-resistant raw materials with large particle sizes and large quantities are crushed, proportioned, and mixed, and then subjected to high-temperature granulation and aging for the first time. The sub-high temperature granulation temperature is not lower than 95°C. After the granulation is cooled, the feed granulation is finely crushed, and the heat-sensitive raw materials in the feed formula are proportioned and mixed, and then the second low-temperature granulation is performed after mixing; the finished product is packaged after cooling.

Embodiment 3

[0022] A processing method of high-efficiency and high-quality sow feed. First, the energy raw materials, protein raw materials, and high-temperature-resistant raw materials with large particle sizes and large quantities are crushed, proportioned, and mixed, and then subjected to high-temperature granulation and aging for the first time. The sub-high temperature granulation temperature is not lower than 95°C. After the granulation is cooled, the feed granulation is finely crushed, and the heat-sensitive raw materials in the feed formula are proportioned and mixed, and then the second low-temperature granulation is performed after mixing; the finished product is packaged after cooling. The heat-sensitive raw materials are dairy products, minerals, premixed feed and pharmaceutical additives. The premixed material includes multiple vitamins, multiple trace elements, amino acid additives, enzyme preparations and probiotics. The energy feed with large particle size and large quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com