Enzyme pickled vegetable and preparation method thereof

A kimchi and enzyme technology, applied in the field of enzyme kimchi and its preparation, can solve the problems of air pollution, improper storage and high nitrite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

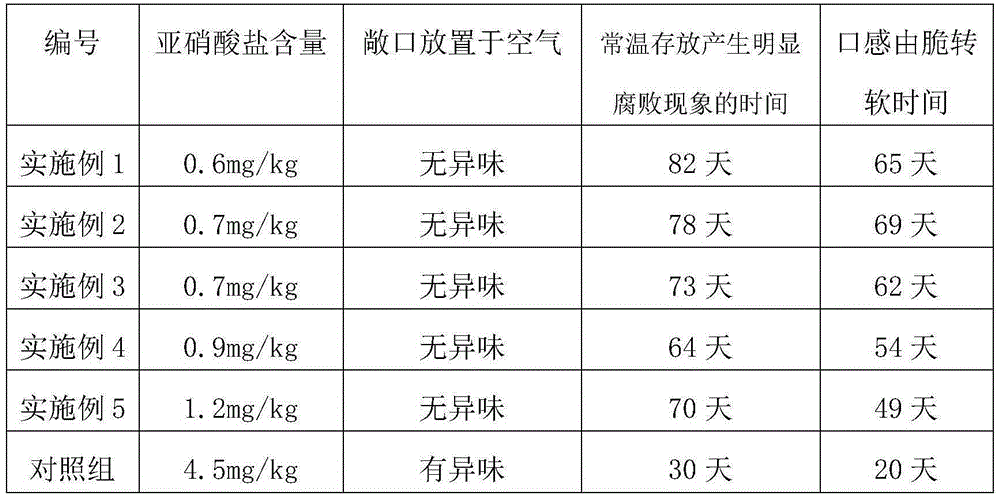

Examples

Embodiment 1

[0026] Step (1): 5 kg of apples, 5 kg of onions, 0.5 kg of garlic, 0.5 kg of ginger powder, 0.1 kg of chili powder, 2 kg of salt, 1 kg of sugar, 0.1 kg of pepper powder, 0.2 kg of lactic acid bacteria, 0.2 kg of yeast, Put 0.2 kg of acetic acid bacteria into a container, add distilled water twice the mass of the above mixture, stir evenly, keep at 25°C for 10 hours, raise the temperature to 36°C and keep for 5 hours, then lower the temperature to 0°C and keep for 5 hours, then Raise the temperature to 31°C for 20 hours, then cool to 20°C;

[0027] Step (2): Cut 100 kg of Chinese cabbage and put the whole leaf into the container containing the mixture after temperature adjustment and fermentation in step (1). The mixture should cover the vegetables, mix evenly, seal it, and let it stand at 30°C 10 days;

[0028] Step (3): cooling the mixture obtained in step (2) to 0° C., then bagging and sealing to obtain the product enzyme kimchi;

[0029] Step (4): Store the enzyme kimchi ...

Embodiment 2

[0031] Step (1): 5 kg of apples, 5 kg of onions, 0.5 kg of garlic, 0.5 kg of ginger powder, 0.1 kg of chili powder, 2 kg of salt, 1 kg of sugar, 0.1 kg of pepper powder, 0.2 kg of lactic acid bacteria, 0.2 kg of yeast, Put 0.2 kg of acetic acid bacteria into a container, add distilled water twice the mass of the above mixture, stir evenly, keep at 25°C for 10 hours, raise the temperature to 36°C and keep for 5 hours, then lower the temperature to 0°C and keep for 5 hours, then Raise the temperature to 31°C for 20 hours, then cool to 20°C;

[0032] Step (2): Cut 100 kilograms of white radishes into 1 cm thick slices, put them into a container filled with the temperature-adjusted and fermented mixture in step (1), the mixture should be submerged in the vegetables, mix evenly, seal, and store at 30°C Stand for 10 days;

[0033] Step (3): cooling the mixture obtained in step (2) to 0° C., then bagging and sealing to obtain the product enzyme kimchi;

[0034] Step (4): Store the ...

Embodiment 3

[0036] Step (1): 5 kg of apples, 5 kg of onions, 0.5 kg of garlic, 0.5 kg of ginger powder, 0.1 kg of chili powder, 2 kg of salt, 1 kg of sugar, 0.1 kg of pepper powder, 0.2 kg of lactic acid bacteria, 0.2 kg of yeast, Put 0.2 kg of acetic acid bacteria into a container, add distilled water twice the mass of the above mixture, stir evenly, keep at 25°C for 10 hours, raise the temperature to 36°C and keep for 5 hours, then lower the temperature to 0°C and keep for 5 hours, then Raise the temperature to 35°C for 5 hours, then cool to 20°C;

[0037] Step (2): Cut 100 kilograms of cucumbers into 1 cm thick slices, put them into a container filled with the temperature-adjusted and fermented mixture in step (1), the mixture should be submerged in the vegetables, mix evenly, seal it, and let it stand at 30°C. set for 10 days;

[0038] Step (3): cooling the mixture obtained in step (2) to 0° C., then bagging and sealing to obtain the product enzyme kimchi;

[0039] Step (4): Store t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com