Single/multiple-component droplet preparation device based on integrated micro-channels and control method of single/multiple-component droplet preparation device

A technology for preparing devices and microchannels, which is applied in the direction of fluid controllers, measuring tubes/pipettes, chemical instruments and methods, etc., can solve the problems of long production cycle, unfavorable industrial production, and high cost, and achieve a small number of pumps, Simple structure and operation, good monodispersity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

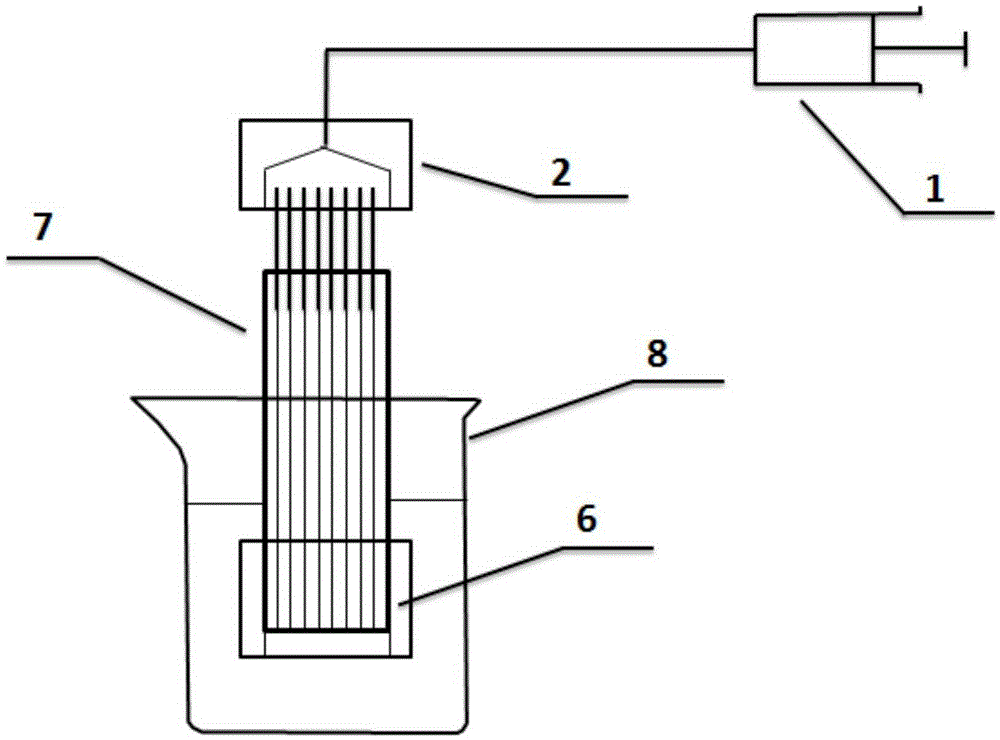

[0047] The preparation of embodiment 1 single-component aqueous phase droplet

[0048] (1) The continuous phase is selected as silicone oil, and the discrete phase is deionized water. Add 5% mass fraction of surfactant (Dow Corning 749) to the silicone oil, and put it in a continuous phase container. Add a small amount of rhodamine b to deionized water and fill into a syringe.

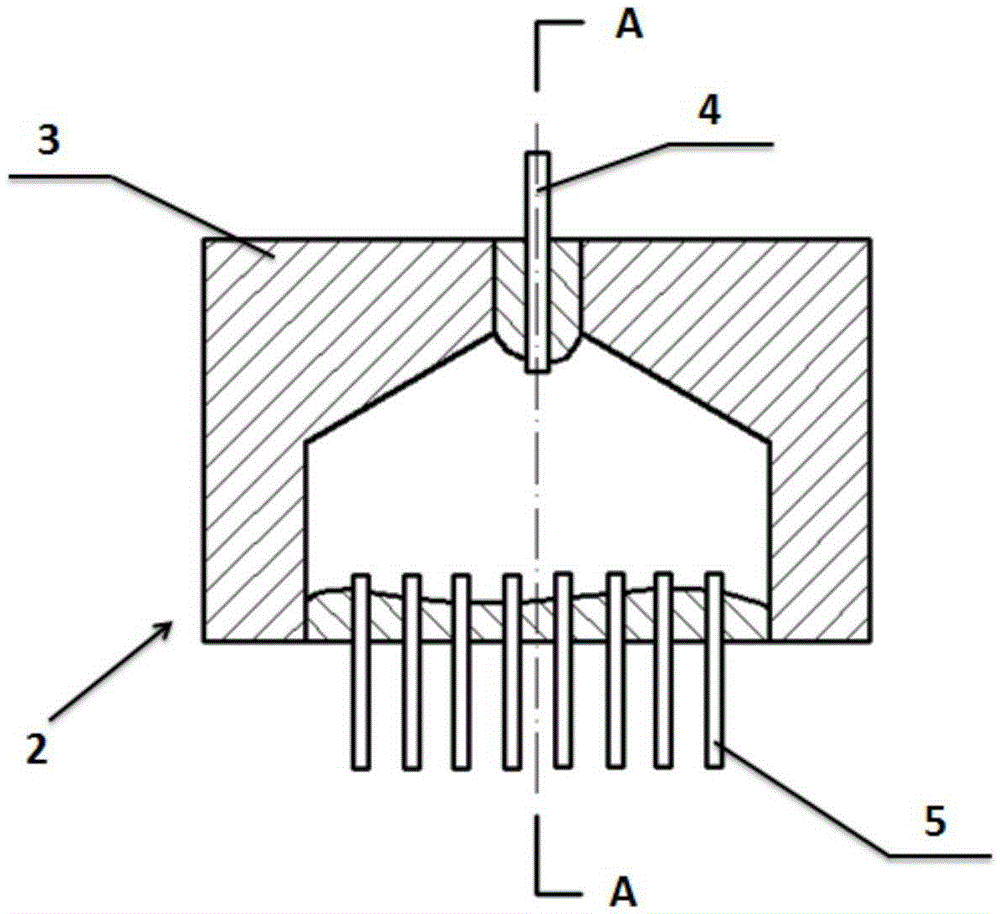

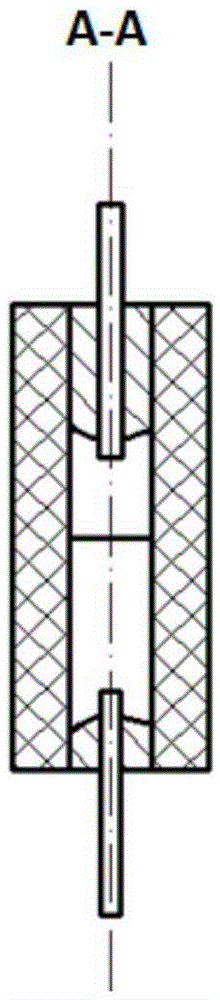

[0049] (2) A preparation device for making single-component liquid droplets according to the above method. The distance between the two splints of the discrete phase outlet joint is h=0.3mm, and the distance between the microchannel outlet and the underside of the discrete phase outlet joint is 1.3mm. In this example, two channels (3rd and 6th) are used to prepare droplets at the same time. In this example, the flow rate of deionized water is set to 5mL / h as required. Turn on the syringe pump and adjust to the stated flow.

[0050] (3) After the deionized water reaches the outlet joint of the discr...

Embodiment 2

[0051] Determination of Mechanism Transition Critical Flow Rate during Example 2 Single-channel Droplet Preparation

[0052] (1) The continuous phase is selected as silicone oil plus 5% Dow Corning 749, and the discrete phase is deionized water plus a small amount of rhodamine b. The viscosity of water is 1.005mPa·s, the surface tension between silicone oil and water is about 2mN / m, and the inner diameter of the channel is 500 microns.

[0053] (2) A preparation device for making single-component liquid droplets according to the above method. The distance between the two splints of the discrete phase outlet joint is h=0.3mm, and the distance between the microchannel outlet and the underside of the discrete phase outlet joint is 1.3mm.

[0054] (3) In this embodiment, a single channel is used to prepare droplets, and the flow rate is between 2mL / hr and 66mL / hr, and a value is taken every 4mL / hr. The obtained droplet size is as follows Figure 8 shown. It can be seen that whe...

Embodiment 3

[0055] The preparation of embodiment 3 two-component aqueous phase droplets

[0056] (1) Select the continuous phase as silicone oil, add 5% mass fraction of surfactant (Dow Corning 749) into the silicone oil, and put it in the continuous phase container. The first discrete phase was selected as deionized water with a small amount of rhodamine b added and loaded into a syringe. The second discrete phase was chosen as deionized water with a small amount of Nile blue added and loaded into another syringe.

[0057] (2) A preparation device for making two-component liquid droplets according to the above method. The distance between the two splints of the discrete phase outlet joint is h=0.3mm, and the distance between the microchannel outlet and the underside of the discrete phase outlet joint is 1.3mm. In this embodiment, two channels are used to prepare two-component droplets, and the two channels are respectively connected to deionized water added with rhodamine b and deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com