Tendon-driving robot finger mechanism

A robot finger and tendon drive technology, applied in the field of robotics, can solve the problems of high machining cost, reduced finger reliability, complex transmission structure, etc., and achieve the effect of simplifying drive and transmission, simple structure, and reducing the weight of fingers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

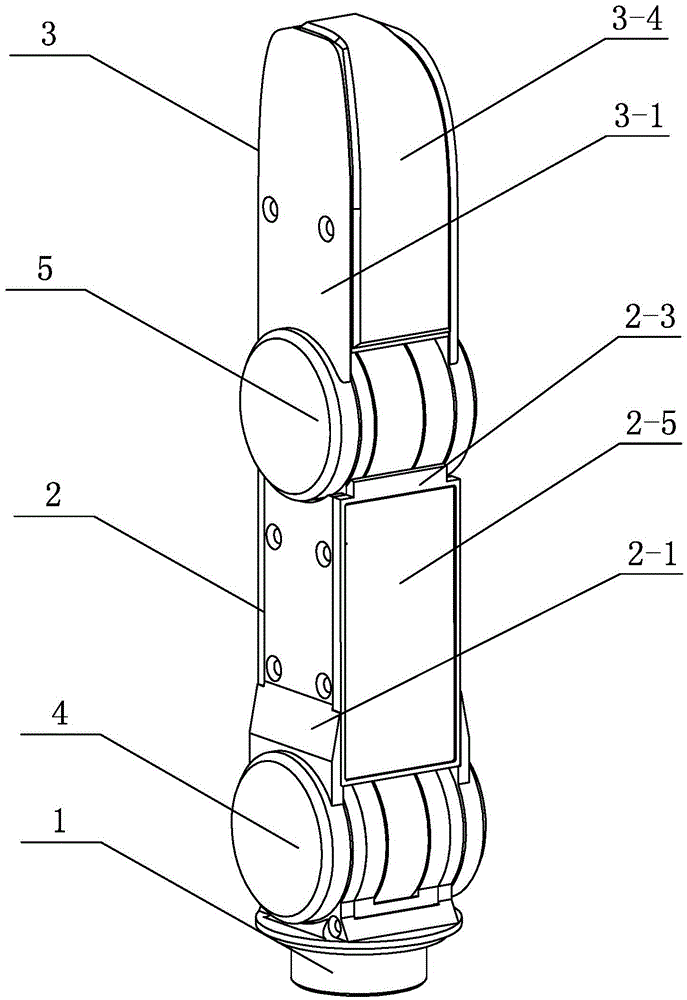

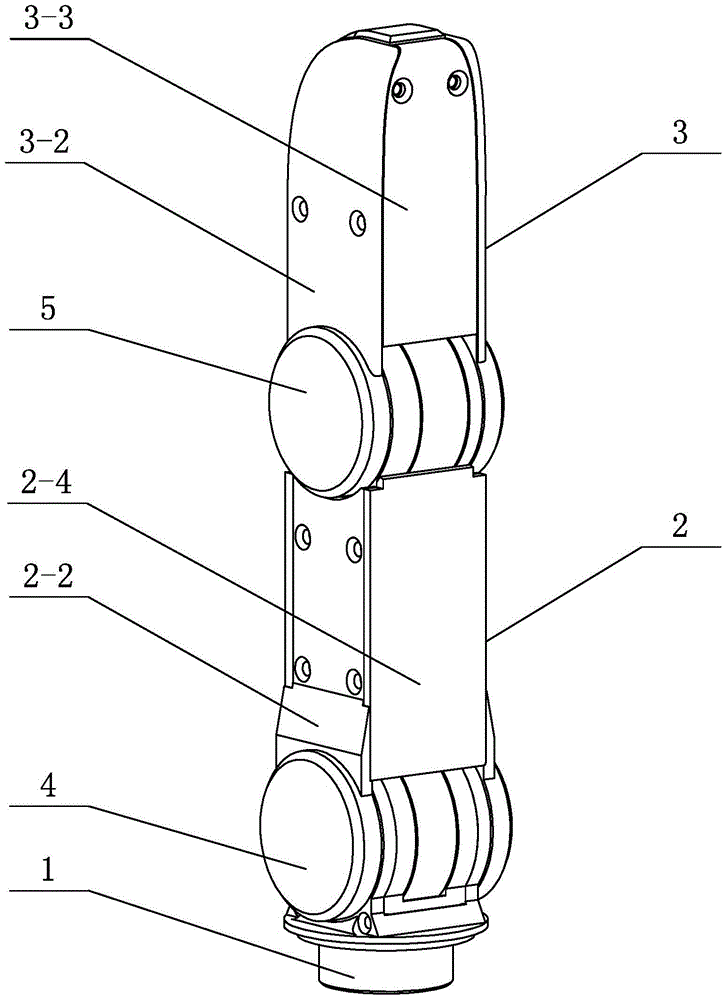

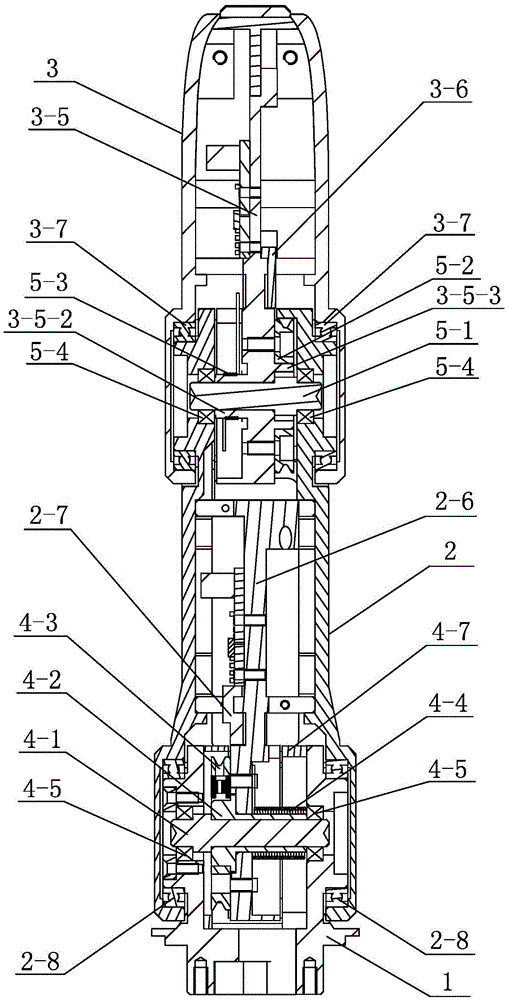

[0029] Specific implementation one: as Figure 1 to Figure 10 As shown, this embodiment describes a tendon-driven robot finger mechanism, comprising a base 1, a proximal phalanx 2, a distal phalanx 3 and two pitching joints, the two pitching joints are the base Joint 4 and end joint 5; the proximal phalanx 2 includes a proximal phalanx housing, a proximal phalangeal force transmission member 2-6 and two proximal phalangeal support bearings 2-8, and the proximal phalangeal housing includes a proximal phalanx housing. The left side plate of the phalanx 2-1, the right side plate of the proximal phalanx 2-2, the front cover plate of the proximal phalanx 2-3 and the rear cover plate of the proximal phalanx 2-4, the said rear cover plate of the proximal phalanx 2- 4 and the proximal phalanx front cover plate 2-3 are respectively connected with the proximal phalanx left side plate 2-1 and the proximal phalanx right side plate 2-2 (through screws); the upper end of the base 1 is provi...

specific Embodiment approach 2

[0033] Specific implementation two: as Figure 1 to Figure 3 As shown, in the tendon-driven robotic finger mechanism described in Embodiment 1, the base 1, the proximal phalanx shell and the terminal phalanx shell are all made of polyimide non-metallic materials.

specific Embodiment approach 3

[0034] Specific implementation three: as image 3 As shown, in the tendon-driven robotic finger mechanism described in the second embodiment, the proximal phalanx force transmission members 2-6 and the end phalangeal force transmission members 3-5 are both made of aluminum alloy materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com