Processing method of confecting polymer water through oxidization method

A treatment method and a technology of mixing polywater, applied in the direction of oxidized water/sewage treatment, multi-stage water treatment, mining wastewater treatment, etc., can solve the problem of polymer solution viscosity reduction and achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

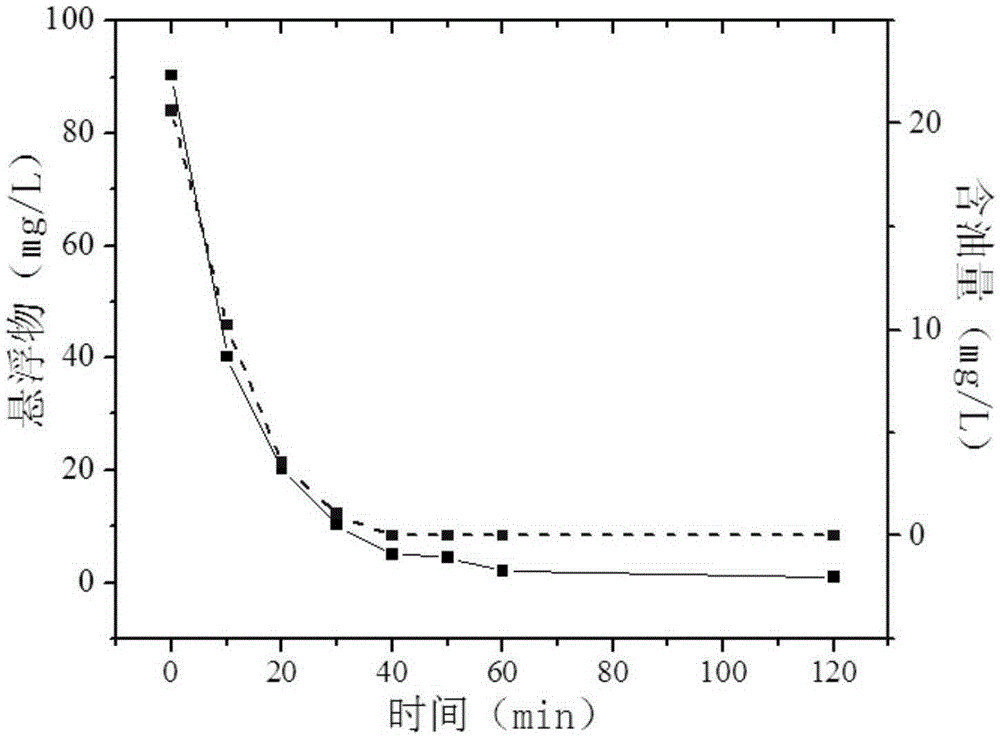

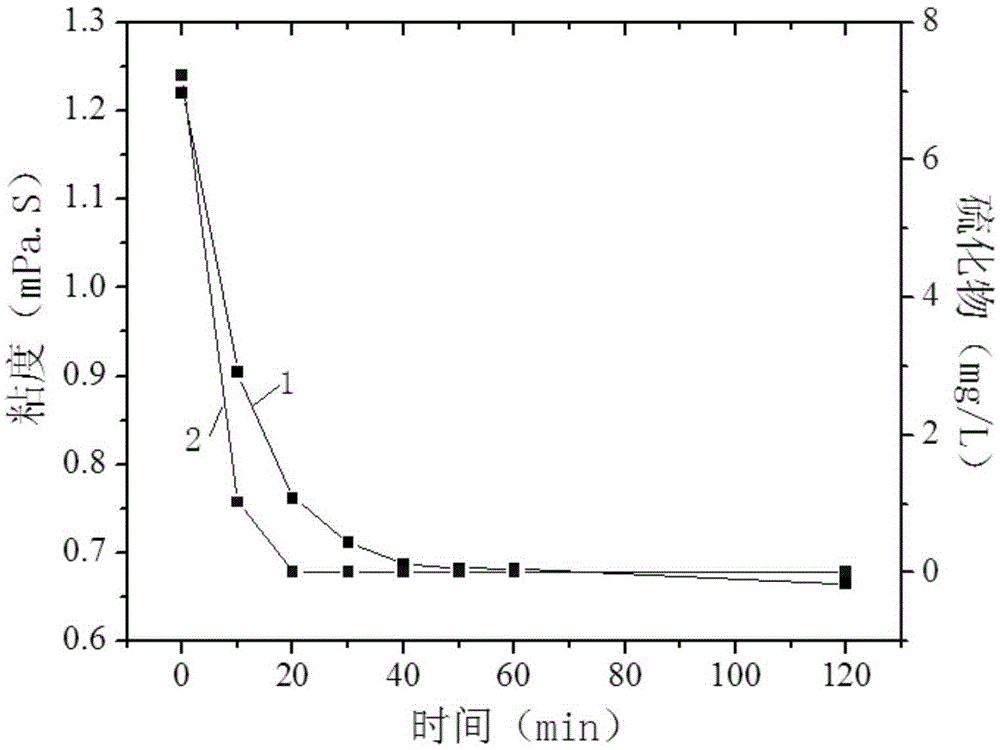

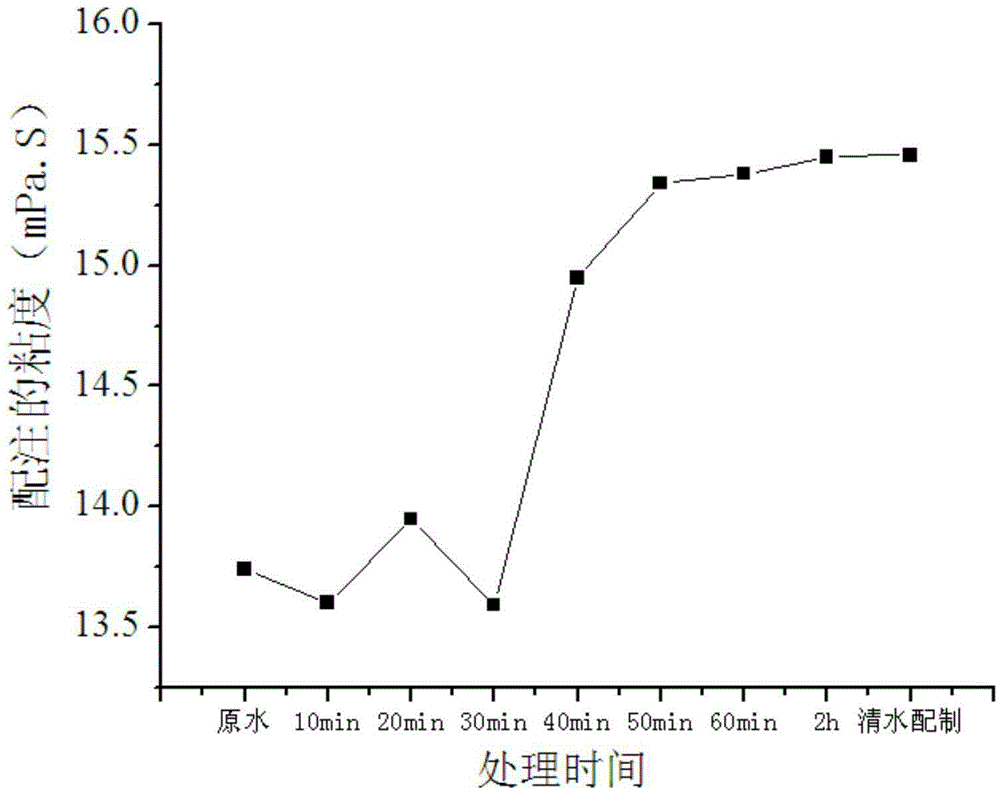

[0014] Specific embodiment one: this embodiment utilizes the oxidation method to mix the processing method of polywater, specifically carry out according to the following steps:

[0015] Pass the compounded water into the reactor, and at the same time pass ozone into the reactor, and treat it for 10 to 60 minutes to complete the treatment method of the compounded water by oxidation method; wherein the reactor is embedded with an ultraviolet lamp, and the emission wavelength of the ultraviolet lamp is The wavelength is 250-260nm, and the power is 35-45W.

specific Embodiment approach 2

[0016] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the input amount of ozone in this method is 30-40 mg / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the input amount of ozone in this method is 33.3 mg / L. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com