Building heat preservation material with excellent fireproof performance

A technology of thermal insulation materials and composite materials, which is applied in the field of building materials and can solve problems such as adverse effects on the health of workers and the environment, limited addition of flame retardants, and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

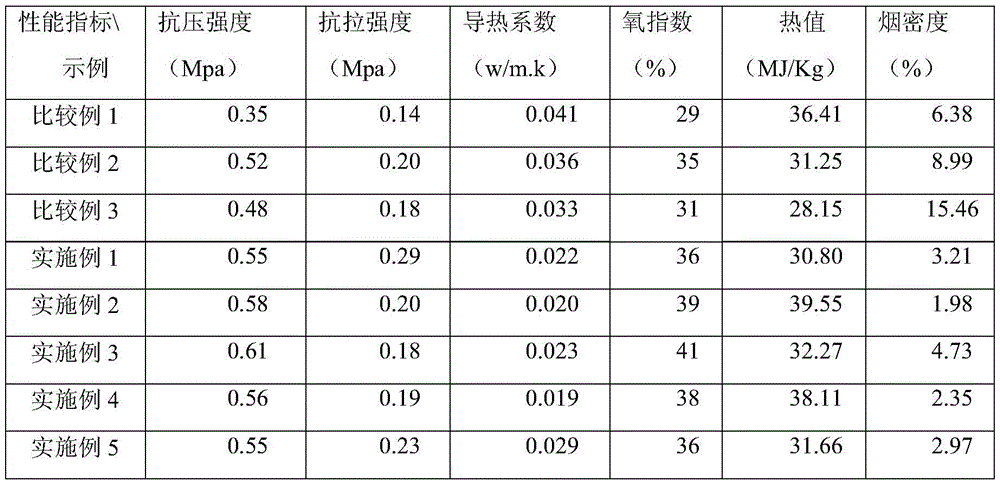

Examples

Embodiment 1

[0064] The manufacture method of the flame retardant insulation board of this embodiment is as follows:

[0065] One, prepare graphene, comprise the steps:

[0066] (1) Preparation of expanded graphite. Among them, graphite oxide is firstly placed in a crucible, then the muffle furnace is heated to a certain temperature, the crucible is put into the muffle furnace and kept for a certain period of time, and then the crucible is taken out to obtain expanded graphite. Wherein, the heating rate of the heating muffle furnace is 10° C. / min, the muffle furnace is heated to 1000° C., and the holding time of the crucible in the muffle furnace is 3 minutes.

[0067] (2) Dispersing expanded graphite in water, adding polystyrene pellet water dispersion and ultrasonication to obtain expanded graphite-polystyrene composite dispersion; wherein, the mass ratio of expanded graphite to water is 1:2, and expanded graphite The mass ratio to the polystyrene pellet water dispersion is 60:1, and t...

Embodiment 2

[0084] The manufacture method of the flame retardant insulation board of the present embodiment is as follows:

[0085] One, prepare graphene, comprise the steps:

[0086] (1) Put the graphite oxide in the crucible, heat the muffle furnace to 1100°C, and the heating rate is 15°C / min, put the crucible into the muffle furnace and keep it warm for 5 minutes, then take out the crucible to obtain expanded graphite.

[0087] (2) Disperse expanded graphite in water, the mass ratio of expanded graphite to water is 1:2, add polystyrene pellet water dispersion, the mass ratio of expanded graphite to polystyrene pellet water dispersion is 70:1 , sonicated for 2h to prepare expanded graphite-polystyrene composite dispersion;

[0088] (3) Suction filter the expanded graphite-polystyrene composite dispersion onto the nickel foam, dry at a drying temperature of 60°C, and dry for 12 hours, place the foamed nickel loaded with expanded graphite-polystyrene in a mixture of hydrazine hydrate and...

Embodiment 3

[0104] The manufacture method of the flame retardant insulation board of this embodiment is as follows:

[0105] One, prepare graphene, comprise the steps:

[0106] (1) Put graphite oxide in a crucible, then heat the muffle furnace to 1100°C at a heating rate of 12°C / min, put the crucible into the muffle furnace and keep it warm for 4 minutes, then take out the crucible to obtain expanded graphite.

[0107] (2) Disperse expanded graphite in water, the mass ratio of expanded graphite to water is 1:2, add polystyrene pellet water dispersion, the mass ratio of expanded graphite to polystyrene pellet water dispersion is 70:1 , sonicated for 2h to prepare expanded graphite-polystyrene composite dispersion;

[0108] (3) Suction filter the expanded graphite-polystyrene composite dispersion onto the foamed nickel, the speed of suction filtration is 4L / s, dry, the drying temperature is 60°C, and the drying time is 11h, the expanded graphite-polystyrene is loaded Nickel foam reacts in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com