Anionic clean fracturing fluid and preparing method thereof

A clean fracturing fluid, anionic technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance, etc., to achieve the effect of complete gel breaking, high apparent viscosity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides an anionic clean fracturing fluid, which is prepared through the following steps:

[0028] Prepare 200 mL of an aqueous solution containing 0.8 wt % potassium hydroxide at room temperature to obtain an alkaline solution, the pH of which is 11;

[0029] Heat the alkali solution to 40-60°C, slowly add 5.0g oleic acid and 5.0g erucic acid in sequence, continue to add a mixture of 0.8g octadecyl dihydroxyethyl betaine and 1.5g cyclohexanol, and stir evenly , add 4.0g butanol under continuous stirring to form a mixed solution;

[0030] The mixed solution was naturally cooled to room temperature, then 8.0 g of potassium chloride was added, and the stirring was continued until a uniform jelly was formed;

[0031] The gel is aged at room temperature for 10-24 hours to form an anionic clean fracturing fluid.

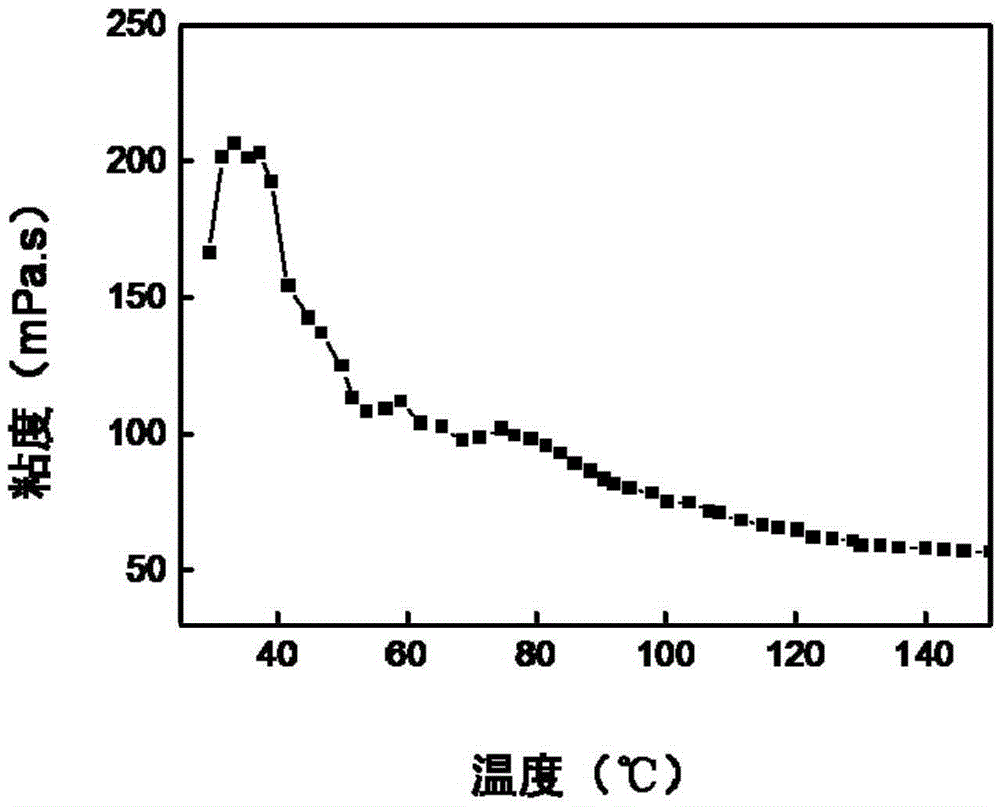

[0032] The fracturing fluid in 170s -1 The viscosity-temperature curve under figure 1 As shown, at 150℃, 170s -1 The temperature resistance a...

Embodiment 2

[0034] This embodiment provides an anionic clean fracturing fluid, which is prepared through the following steps:

[0035] Prepare 200 mL of an aqueous solution containing 1.2 wt % potassium hydroxide at room temperature to obtain an alkaline solution, the pH of which is 13;

[0036] Heat the alkali solution to 40-60°C, slowly add 5.0g oleic acid and 7.0g erucic acid in turn, continue to add 1.2g octadecyldimethylsulfopropyl betaine and 2.0g 2-ethylhexanol The mixture was stirred evenly, and 5.0 g of propanol was added under continuous stirring to form a mixed solution;

[0037] The mixed solution was naturally cooled to room temperature, then 10.0 g of potassium chloride was added, and the stirring was continued until a uniform jelly was formed;

[0038] The gel is aged at room temperature for 10-24 hours to form an anionic clean fracturing fluid.

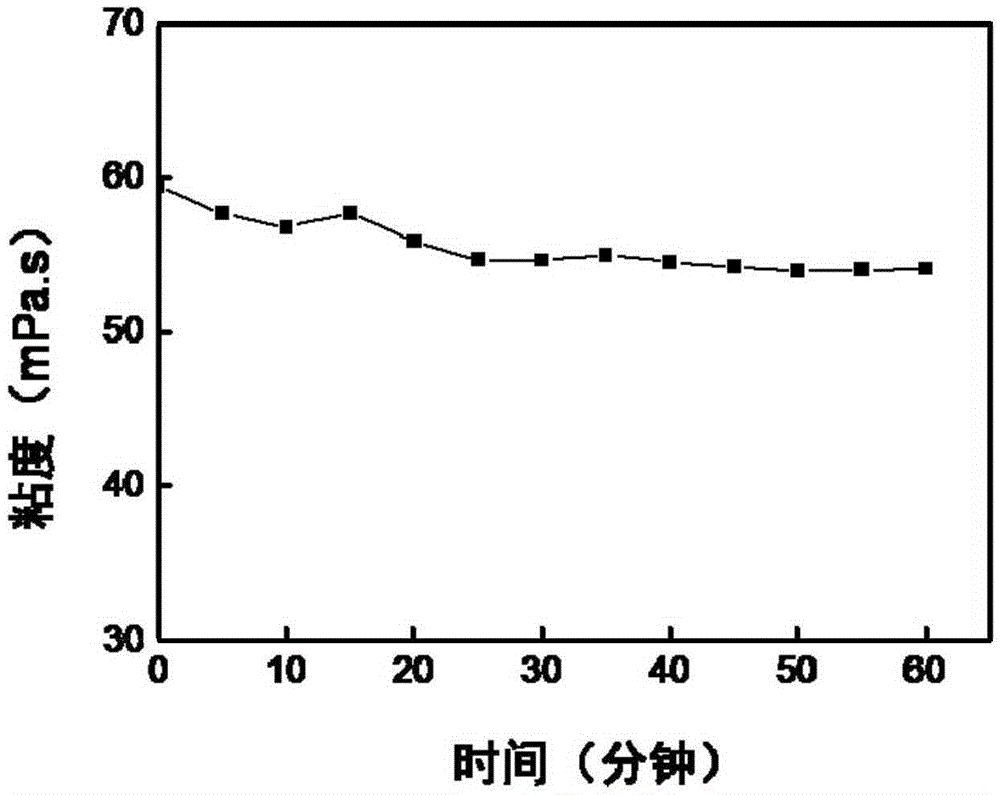

[0039] The pH value of the fracturing fluid is 12, at 30°C, 170s -1 The viscosity at 219mPa·s; at 150℃, 170s -1 The viscosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com