Method for purifying and concentrating beet sugar manufacture clarified juice and sugar making method adopting method for purifying and concentrating beet sugar manufacture clarified juice

A technology for clear juice and sugar beet, which is applied in the purification of sugar juice, sugar production, and purification by physical methods, etc., can solve the problems of insufficient sugar content and purity of clear juice, low sugar production efficiency, heavy evaporation load, etc. Simple and reliable, easy to operate, small effect of equipment modification work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

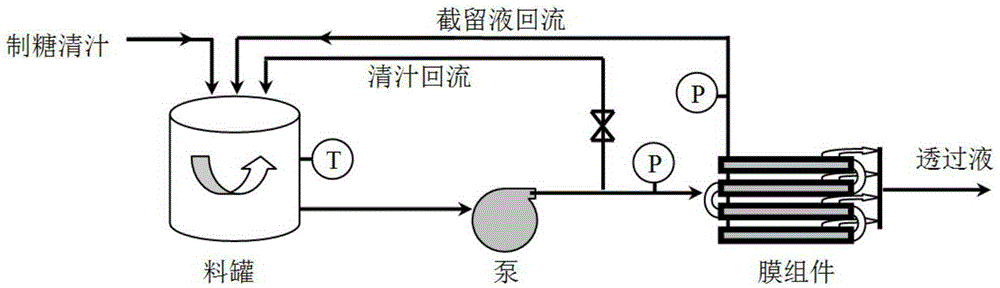

[0058] Film Type: roll film

[0059] Cut-off molecular weight: about 400Da, membrane area 2.6m 2

[0060] Equipment: Roll-type membrane (model SPPM-25S-1, Sanda Membrane Environmental Technology Co., Ltd.) Table 2 Roll-type membrane equipment operating parameters table

[0061]

[0062] Table 3 Nanofiltration processing material parameter list

[0063]

[0064] Table 4 Material characteristic parameter table

[0065]

[0066] Compared with the beet sugar clear juice before nanofiltration treatment, the obtained concentrated clear juice has a brix increase of 6.1Brix, a 5.6wt% increase in sugar content, and an increase in purity of 1.38 percentage points; after calculation, nanofiltration can reduce the evaporation load by 37.9% . In the present invention, the "evaporative load reduction percentage"=[1-(water content in the concentrate after nanofiltration treatment÷water content in clear juice before nanofiltration treatment)]×100%.

Embodiment 2

[0068] Film Type: roll film

[0069] Cut-off molecular weight: about 400Da, membrane area 2.6m 2

[0070] Equipment: roll membrane (model SPPM-25S-1, Sanda Membrane Environmental Technology Co., Ltd.)

[0071] Table 5 Operation parameter list of roll-type membrane equipment

[0072]

[0073] Table 6 Nanofiltration processing material parameter table

[0074]

[0075] Table 7 Material characteristic parameter table

[0076]

[0077] Compared with the beet sugar clear juice before nanofiltration treatment, the obtained concentrated clear juice has a brix increase of 4.9Brix, a sugar content increase of 4.55wt%, and a purity increase of 1.03 percentage points; after calculation, nanofiltration can reduce the evaporation load by 34.3% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com