Low-hydration magnesium oxide coating for high magnetic induction grain-oriented silicon steel

A high magnetic induction orientation, magnesium oxide technology, applied in the field of magnesium oxide, can solve the problems of reduced reactivity, lack of expression of hydration rate surface defects, influence of thickness coating adhesion, etc., to ensure consistency and avoid overoxidation. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

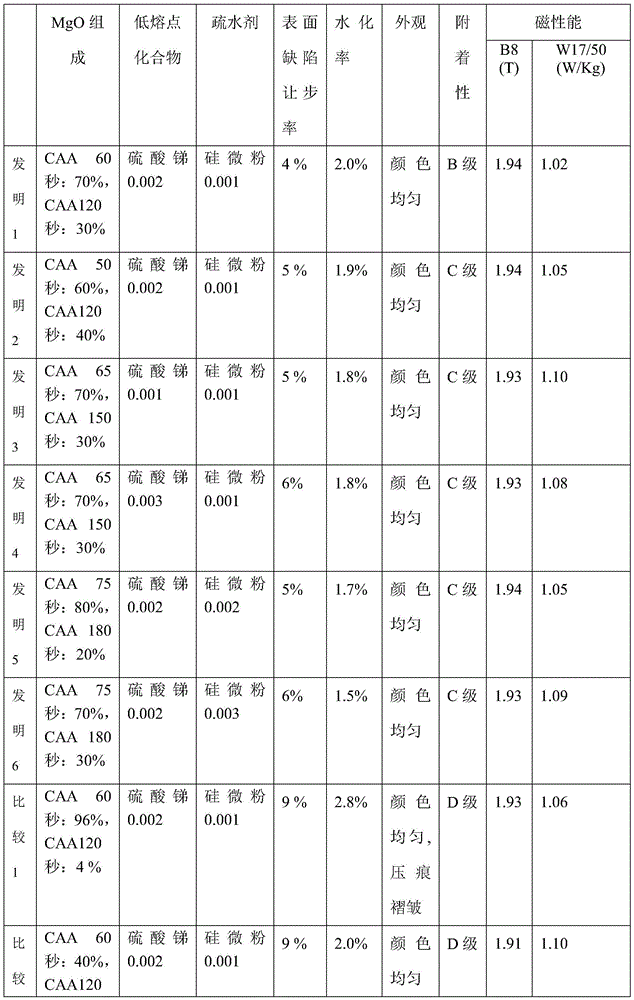

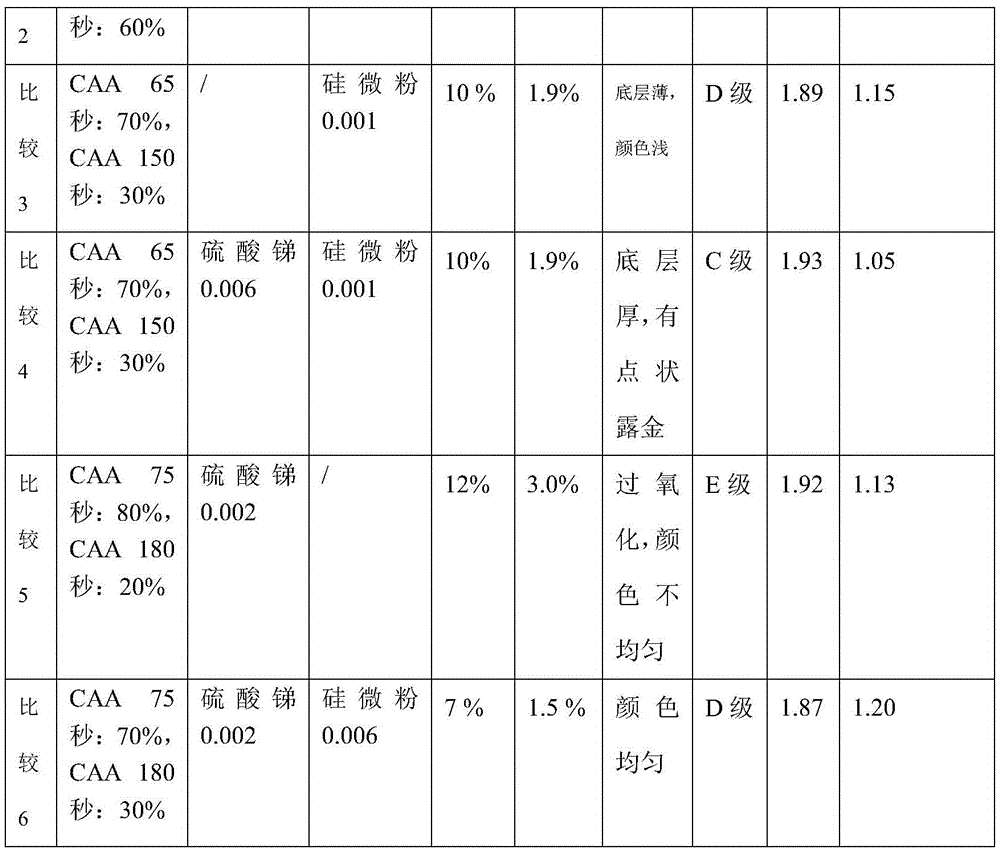

Examples

Embodiment 1

[0023] A low-hydration magnesia coating for high magnetic induction oriented silicon steel, including 10kg of special magnesia, 0.5kg of titanium dioxide, 0.001kg of antimony sulfate, 0.001kg of silicon micropowder, and 80kg of Deionized water, the above ingredients were mixed for 60 minutes under stirring at 1000r / min, and the reaction temperature was 0°C to make a low-hydration magnesium oxide coating; the content of calcium oxide in special magnesium oxide was 0.02kg (or 0.03kg or 0.04 kg), the content of sulfate is 0.02kg (or 0.03kg or 0.05kg), the content of chloride is 0.01kg (or 0.015kg or 0.02kg), the content of magnesium oxide is 9.9kg (or 9.8kg or 9.7kg) , the impurity content is 0.05kg (or 0.125kg or 0.19kg), magnesium oxide consists of 4.95kg (or 4.9kg or 4.85kg) active magnesium oxide and 4.95kg (or 4.9kg or 4.85kg) inactive magnesium oxide, active Magnesia has a 40% CAA value of 50 seconds and an average particle size of 1-5 microns, and non-reactive magnesium ox...

Embodiment 2

[0025] A low-hydration magnesia coating for high magnetic induction oriented silicon steel, comprising 12kg of special magnesia, 0.8kg of titanium dioxide, 0.003kg of antimony sulfate, 0.003kg of silicon micropowder, and 85kg of Deionized water, the above ingredients were mixed for 75 minutes under stirring at 1300r / min, and the reaction temperature was 3°C to make a low-hydration magnesium oxide coating; the content of calcium oxide in special magnesium oxide was 0.024kg (or 0.036kg or 0.048 kg), the content of sulfate is 0.024kg (or 0.036kg or 0.06kg), the content of chloride is 0.012kg (or 0.018kg or 0.024kg), the content of magnesium oxide is 11.88kg (or 11.76kg or 11.64kg) , the impurity content is 0.06kg (or 0.15kg or 0.228kg), the magnesia is composed of 8.316kg (or 8.232kg or 8.148kg) active magnesia and 3.564kg (or 3.528kg or 3.492kg) inactive magnesia, active Magnesia has a 40% CAA value of 65 seconds and an average particle size of 1-5 microns, and non-reactive magn...

Embodiment 3

[0027]A low-hydration magnesia coating for high magnetic induction oriented silicon steel, including 15kg of special magnesia, 1.0kg of titanium dioxide, 0.005kg of antimony sulfate, 0.005kg of silicon micropowder, and 90kg of Deionized water, the above ingredients were mixed for 90 minutes under stirring at 1500r / min, and the reaction temperature was 5°C to make a low-hydration magnesium oxide coating; the content of calcium oxide in special magnesium oxide was 0.03kg (or 0.045kg or 0.06 kg), the content of sulfate is 0.03kg (or 0.045kg or 0.075kg), the content of chloride is 0.015kg (or 0.0225kg or 0.03kg), the content of magnesium oxide is 14.85kg (or 14.7kg or 14.55kg) , the content of impurities is 0.075kg (or 0.1875kg or 0.285kg), the magnesium oxide consists of 14.1075kg (or 13.965kg or 13.8225kg) active magnesium oxide and 0.7425kg (or 0.735kg or 0.7275kg) inactive magnesium oxide, the active Magnesia has a 40% CAA value of 80 seconds and an average particle size of 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com