Hardness removing device and method for waste liquid by electric flocculation

An electro-flocculation and waste liquid technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc. High reactivity and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

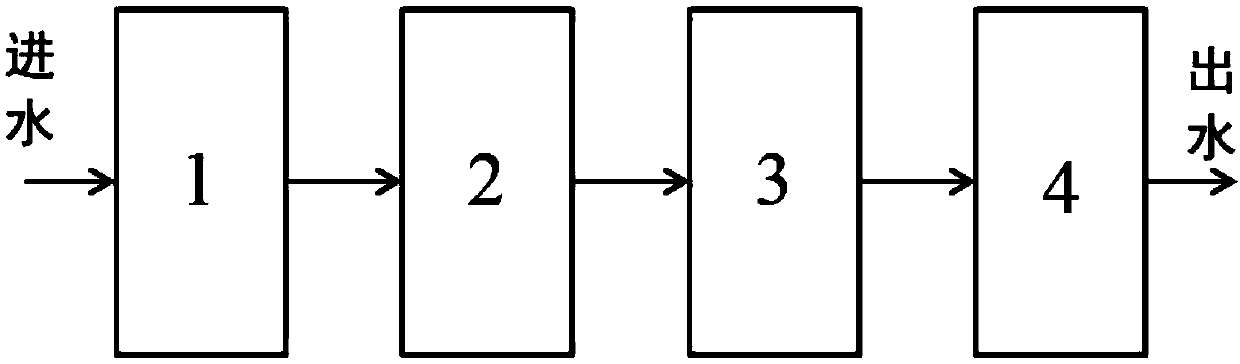

[0049] This implementation provides a waste liquid electroflocculation hard removal device, such as figure 1 As shown, the waste liquid electrocoagulation hard removal device includes a buffer adjustment tank 1, an electrocoagulation reaction tank 2, a water quality adjustment tank 3 and an inclined tube sedimentation separation tank 4, which are connected in sequence;

[0050] The buffer adjustment tank 1 is equipped with a mixer; the entrance and the inside of the electrocoagulation reaction tank 2 are respectively equipped with a water quality online detection system. The water quality online monitoring system is equipped with an automatic water collection and distribution system, a multi-probe online monitoring device and a microcomputer program control module Regular automatic monitoring of water quality indicators through automatic water collection and distribution system and multi-probe online monitoring device to monitor pH, TDS, ORP indicators, and feed back to the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com