Construction and protection method for extremely soft rock foundation

A very soft rock and foundation technology, applied in the field of engineering construction, can solve problems such as failure to meet mechanical and other performance requirements, easy softening, disintegration, low mechanical strength, etc., to protect the natural characteristics and mechanical strength of rock mass, and clean construction methods. , the effect of prolonging the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

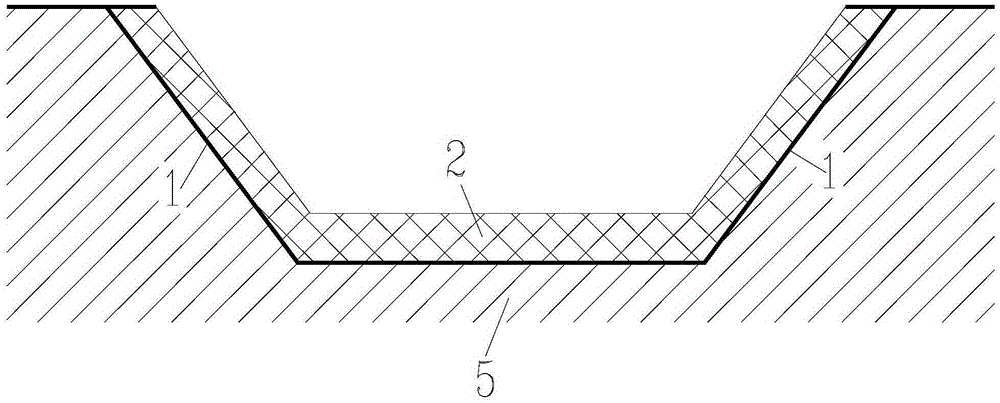

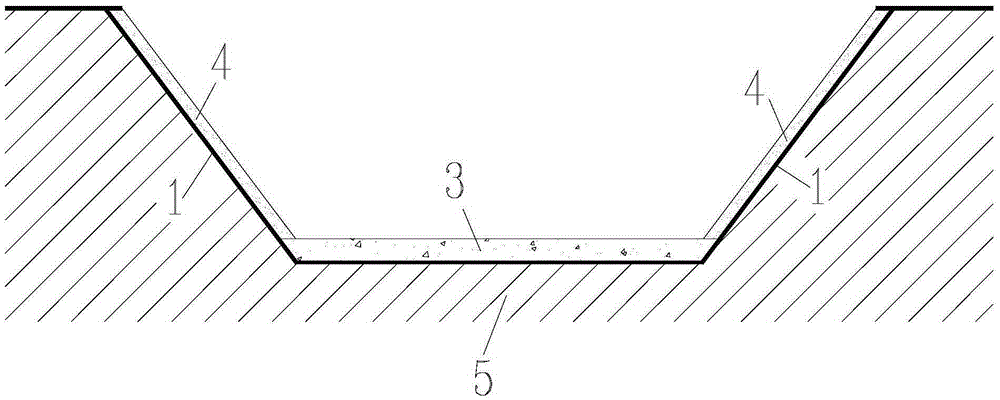

[0026] A construction and protection method for an extremely soft rock foundation, in which a protective layer with a thickness of 0.3 to 0.5 m is reserved before the extremely soft rock foundation is excavated to the foundation surface, and then the protective layer is excavated to the foundation surface by mechanical or manual methods , Clean the base surface, and then spray the cement mortar cover with a thickness of 3-10cm on the slope surface and pour a thick concrete cushion layer with a thickness of 15-25cm to protect the base surface.

Embodiment 2

[0028] The difference from Example 1 is: the excavation of the extremely soft rock foundation adopts the blasting method, the thickness of the protective layer above the foundation surface is 1.5-2.0m, and the upper part of the protective layer 1.0-1.7m is excavated by small-dose blasting. The lower 0.3-0.5m shall be excavated mechanically or manually. For the extremely soft rock that does not need to be excavated by blasting, it is directly excavated by machinery or by hand, and a 0.3-0.5m protective layer is retained.

Embodiment 3

[0030] The difference from Embodiment 1 or 2 is: after the formation of the reserved protective layer, the excavation of the foundation surface is being carried out within 1 to 3 days, and the excavation area is controlled at 100 to 200m 2 Within the range, and do a good job of foundation pit drainage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com