LED (Light Emitting Diode) epitaxial wafer and preparation method therefor

An LED epitaxial wafer, low-temperature technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as segregation, and achieve the effect of reducing the degree of separation, improving the internal quantum efficiency, and reducing the phenomenon of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

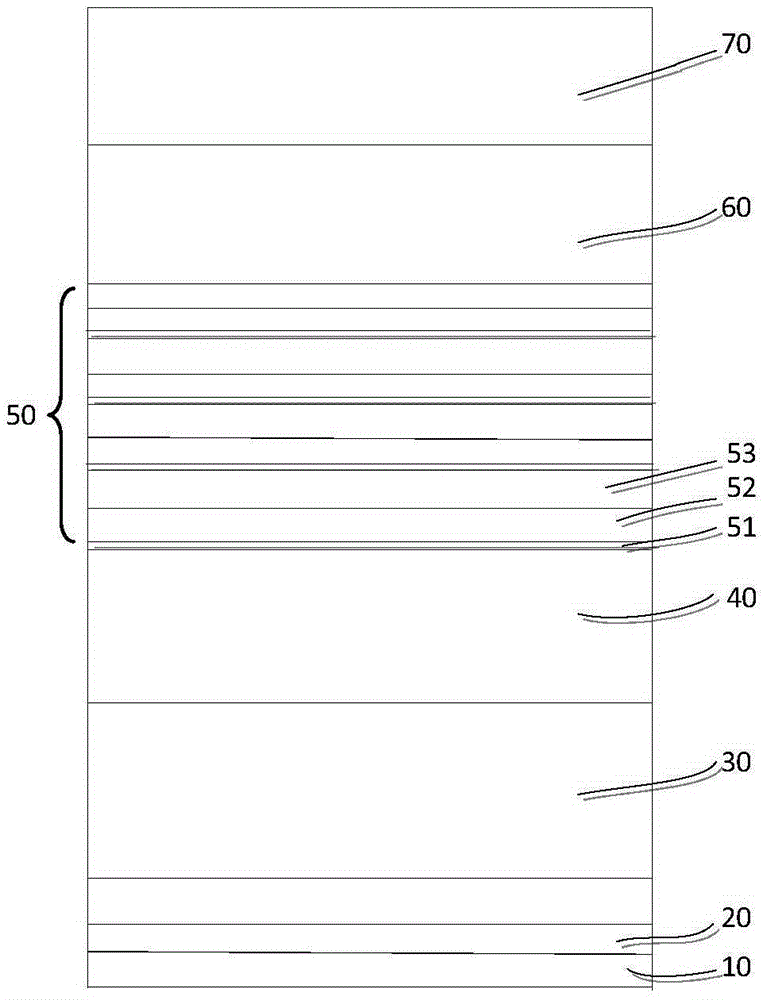

[0050] Another aspect of the present invention provides a method for preparing the above-mentioned LED epitaxial wafer, comprising the following steps:

[0051] A low-temperature buffer GaN layer 20 , an undoped GaN layer 30 and an N-type GaN layer 40 are grown sequentially on the substrate 10 .

[0052] A multi-period quantum well layer 50 is set on the undoped GaN layer 30, and in any period, the x Ga 1-x Before the N layer 52 and the GaN layer 53, the InN thin layer 51 is plated under the conditions of a coating time of 10-60 seconds, an indium source flow rate of 200-1500 sccm, a temperature of 700-750° C., and a pressure of 100-800 mbar.

[0053] A P-type AlGaN layer 60 and a P-type GaN layer 70 are sequentially plated.

[0054] AixtronMOCVD was used to grow LED epitaxial wafers. Low temperature buffer GaN layer 20, undoped GaN layer 30 and N-type GaN layer 40, In x Ga 1-x The N layer 52, the GaN layer 53, the plated P-type AlGaN layer 60, and the P-type GaN layer 70...

Embodiment 2

[0082] 1. Treat the sapphire substrate at high temperature for 3-5 minutes in a hydrogen atmosphere at 1000-1200°C.

[0083] 2. Lower the temperature to 530-560° C., and grow a low-temperature buffer GaN layer with a thickness of 20-30 nm on the sapphire substrate.

[0084] 3. Raise the temperature to 1000-1100°C and continue to grow 3-4um undoped GaN.

[0085] 4. Then firstly grow 3-4μm N-type GaN continuously doped with Si, and the Si doping concentration is 5E+18-2E+19.

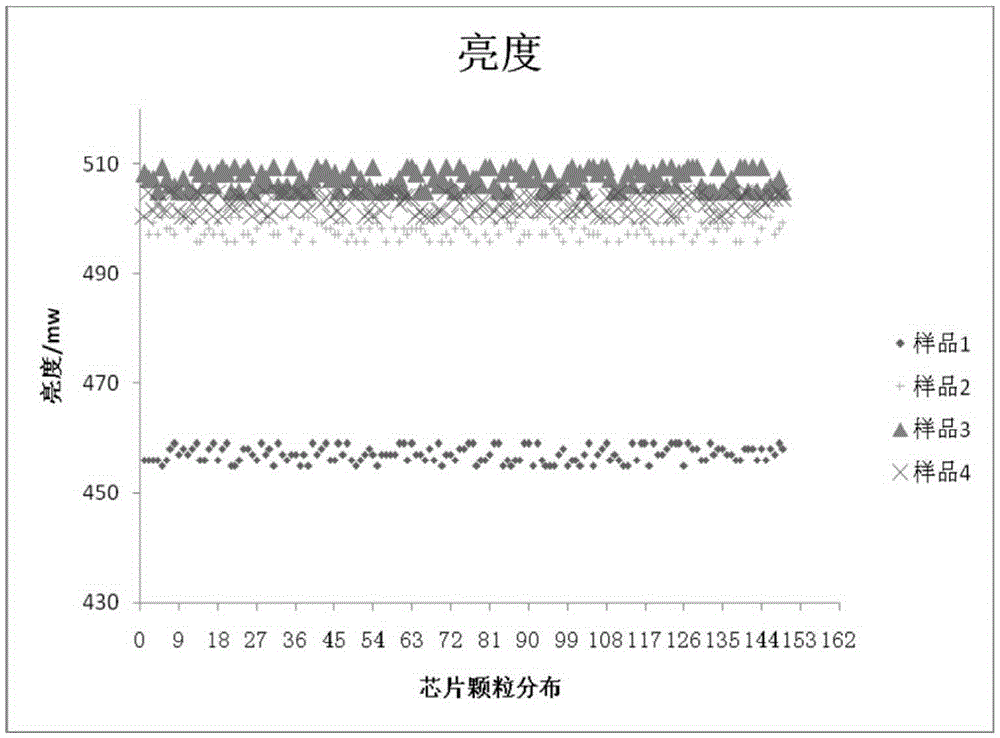

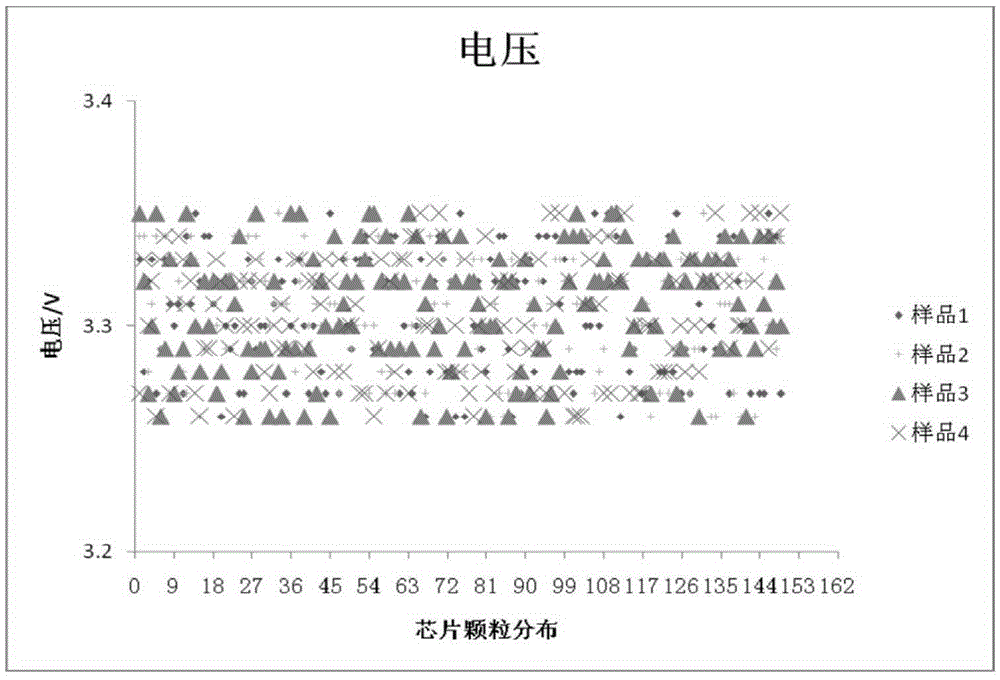

[0086] 5. Periodically grow the light-emitting layer MQW, and grow In-doped 2.5-3nmIn at a low temperature of 700-750°C x Ga 1-x N, x=0.20-0.22 layers, and a 10-12nm GaN layer is grown at a high temperature of 800-850°C. In x Ga 1-x The number of N layer / GaN layer periods is 12. In each period of the quantum well In x Ga 1-x Before N grows, a certain flow rate of TMIn is introduced to prepare a thin layer of InN.

[0087] Preparation conditions of InN thin layer: coating time is 15 seconds, trimethy...

Embodiment 3

[0094] The difference between embodiment 3 and embodiment 2 is that the deposition time of the thin InN layer 51 is 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com