External cavity narrow linewidth laser device

A laser and narrow linewidth technology, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problem that the coherent reception of high-order modulation formats cannot be met, the application prospects of optical transmitters and receivers are not large, and the increase in process and System complexity and other issues, to achieve the effect of reducing coupling coefficient and line width, reducing sensitivity, reducing cavity surface reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

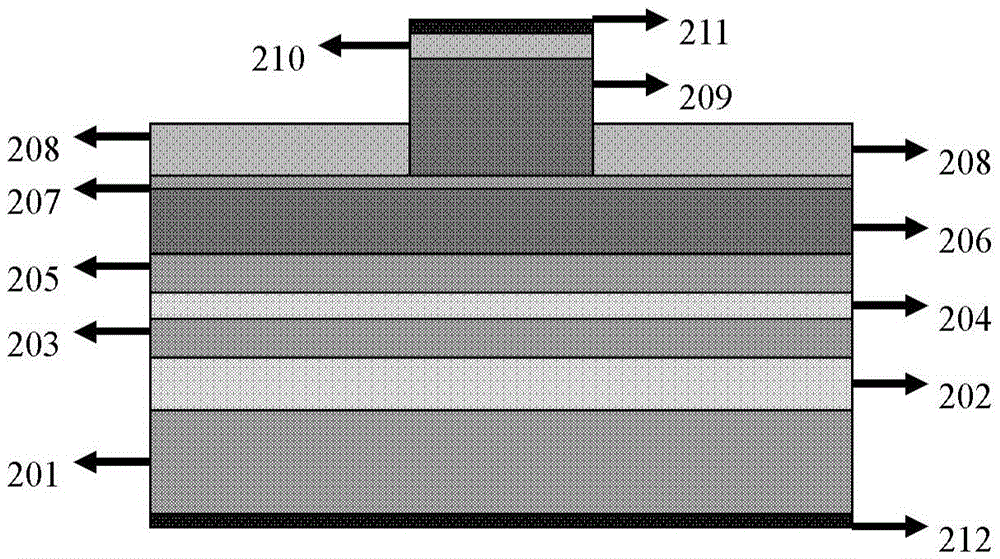

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

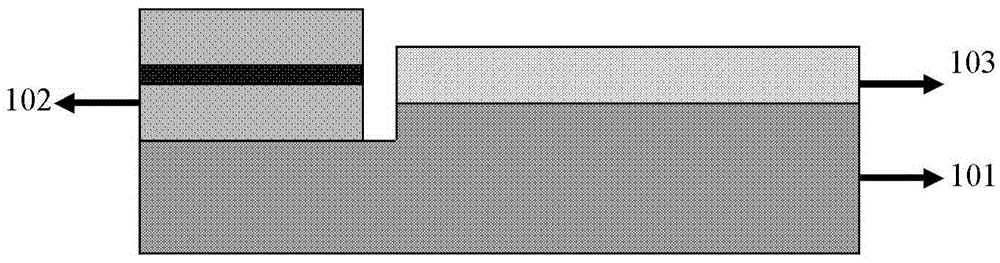

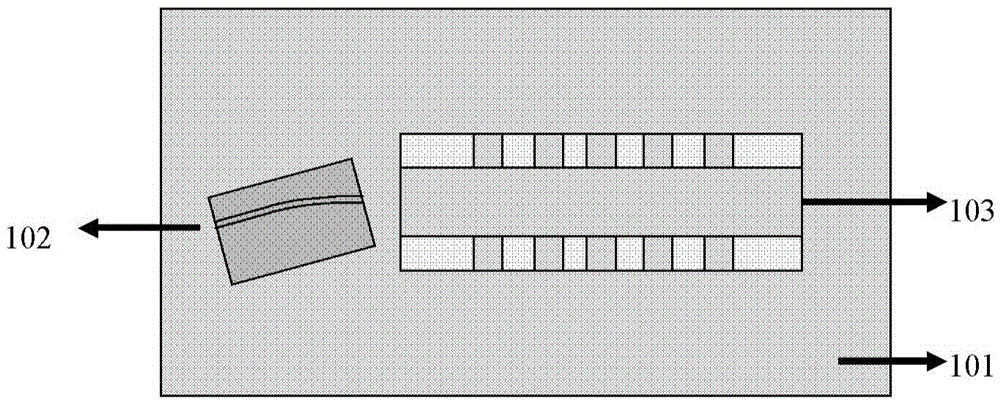

[0049] Figure 1a is a schematic cross-sectional view of an external cavity narrow linewidth laser according to an embodiment of the present invention, such as Figure 1a As shown, the external cavity narrow linewidth laser includes: a semiconductor optical amplifier 102, a planar waveguide grating 103 and a substrate 101, wherein:

[0050] The semiconductor optical amplifier 102 and the planar waveguide grating 103 are bonded to the substrate 101 by bonding to reduce the sensitivity of the laser to vibration, increase the stability of the laser, and reduce the noise of the laser;

[0051] One end of the semiconductor optical amplifier 102 is coated with a high reflection film, and the other end is coated with a high trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com