Method and system for controlling trigger angle of converter valve in direct current transmission system

A direct current transmission system, direct current technology, applied in the direction of output power conversion device, electrical components, power transmission AC network, etc., to achieve the effect of improving stability, ensuring flexibility, and good control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

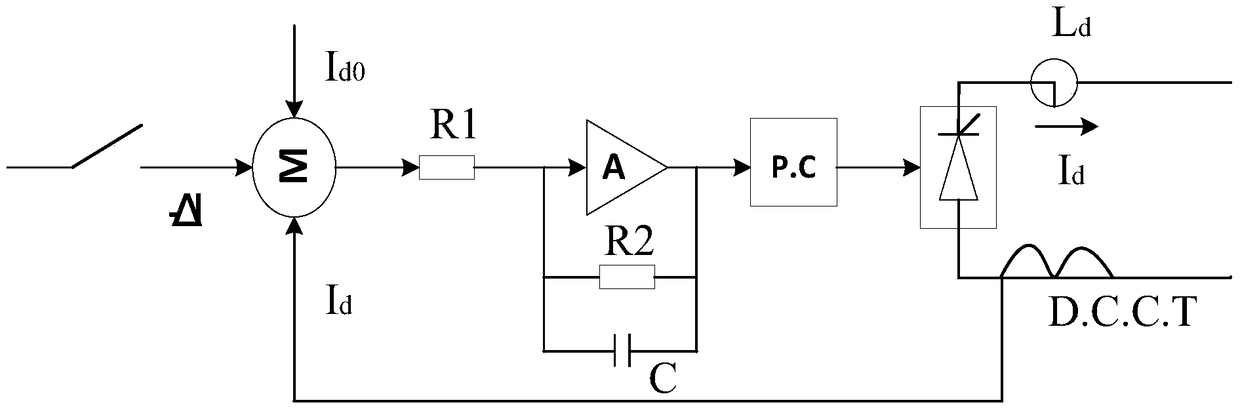

[0023] The control method for the trigger angle of the converter valve of the direct current transmission system provided by the present invention includes the control of the trigger angle of the converter valve on the inverter side and the converter valve on the rectification side. Adopt constant current control.

[0024] The trigger angle control system of a converter valve in a direct current transmission system provided by the present invention includes an inverter side subsystem and a rectification side subsystem.

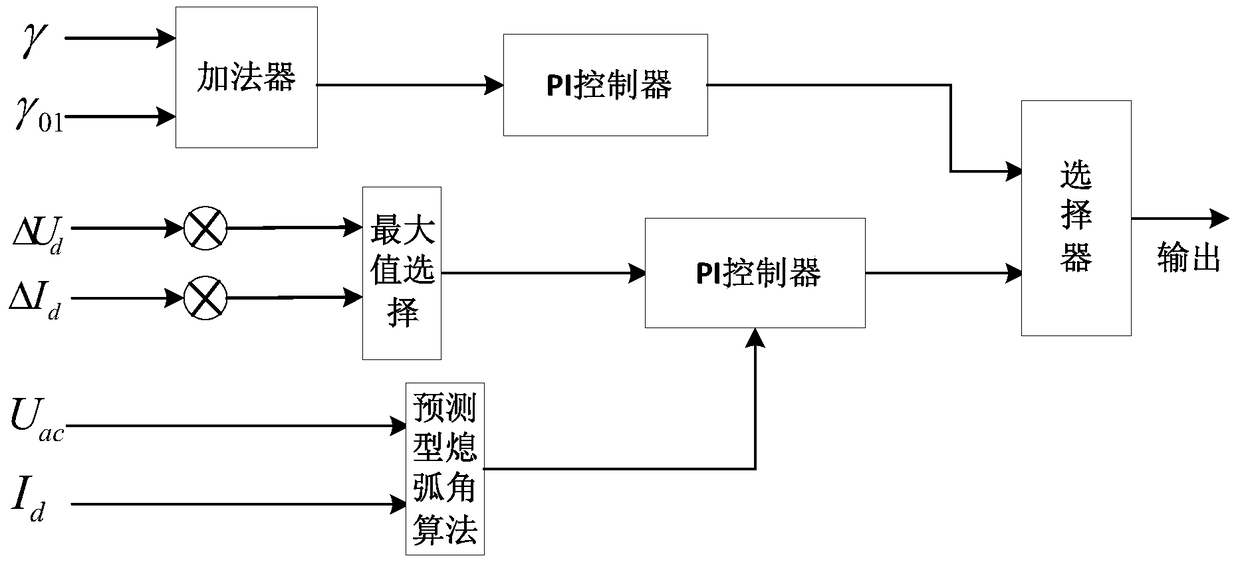

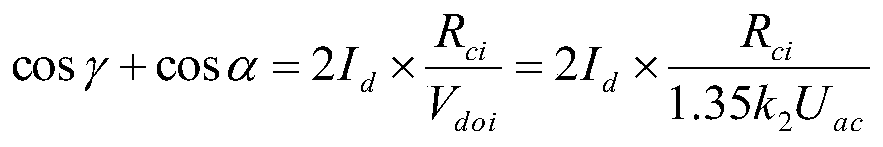

[0025] For inverter side subsystems, such as figure 1 As shown, it includes an adder, a firing angle generation module, a maximum value selector, a first PI controller, a predictive arc-extinguishing angle calculation module and a selector, and the adder is connected to an input end of the selector through the firing angle generation module; The output of the predictive arc extinguishing angle calculation module is connected to one input end of the first PI c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com