Millet vermicelli and manufacturing method thereof

A technology of millet and vermicelli, which is applied in the food field, can solve problems such as backward processing technology, difficult processing technology, and difficulty in grasping the degree of gelatinization, so as to achieve the effect of satisfying dietary health, improving flavor, and enriching varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

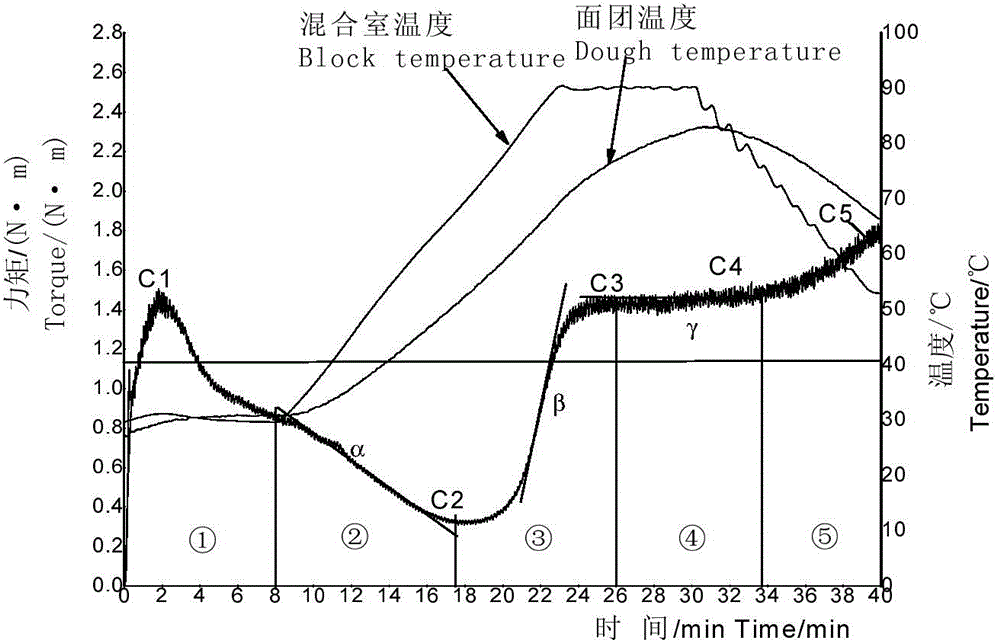

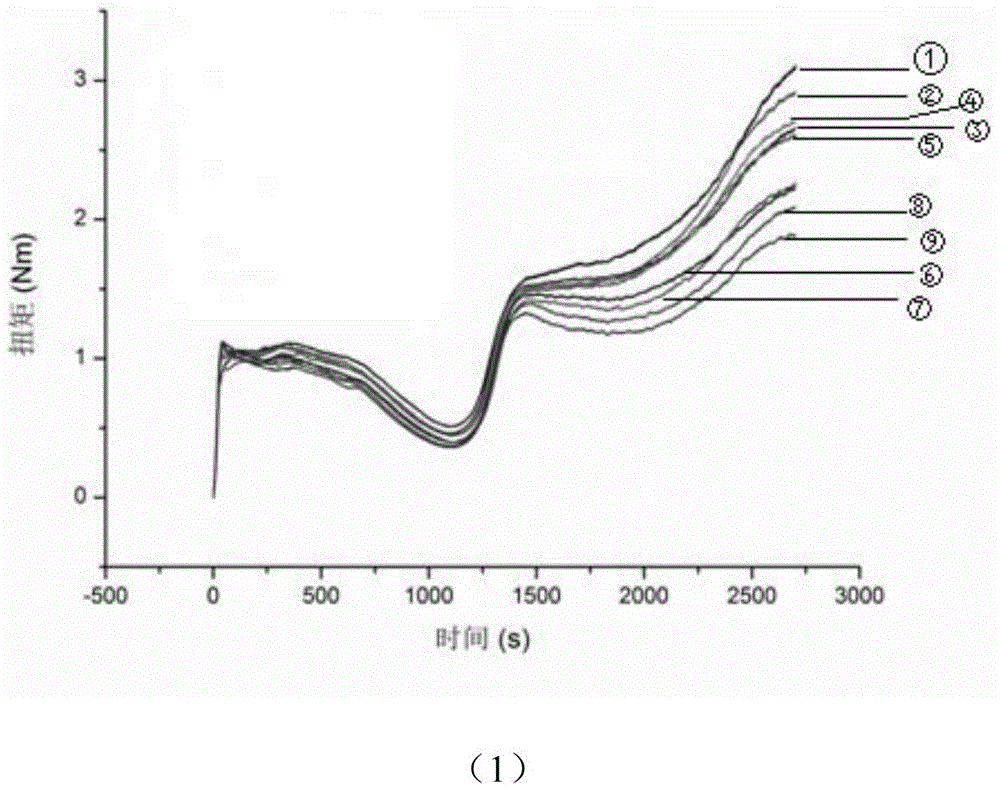

[0037] Embodiment 1, raw millet flour, cooked flour, micropowder 5%-40% mixing test instrument curve

[0038] Determination of Rheological Properties of Dough Mixed with Millet and Flour

[0039] The cooked millet powder used in this embodiment is prepared according to the following steps:

[0040] After crushing the millet through an 80-mesh sieve, adding water until the water content is 16%, extruding and puffing in the extruder, the screw speed is 280r / min, and the temperature gradient is 60°C, 90°C, 120°C, 185°C, After extrusion and puffing, crush and pass through an 80-mesh sieve to obtain cooked millet powder with a particle size of 50 μm-600 μm;

[0041] Millet powder is prepared according to the following steps:

[0042] The millet is graded and crushed in 50 grades, and the millet powder is passed through a sieve of 325 mesh to 2500 mesh to obtain millet powder with a particle size of 5 μm-20 μm;

[0043] The raw millet powder is passed through an 80-mesh sieve to ...

Embodiment 2

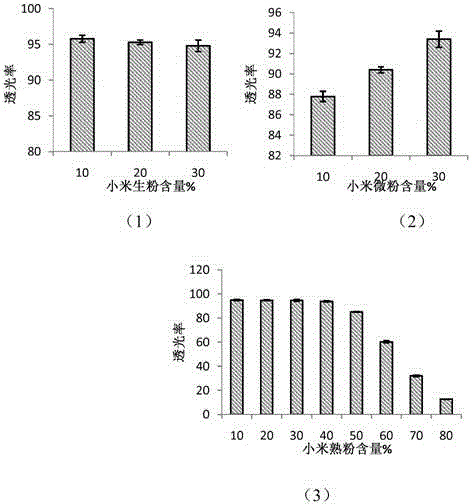

[0063] Embodiment 2, measurement of light transmittance of raw millet powder, cooked powder, and fine powder vermicelli noodle soup

[0064] 1) Make dried noodles according to the following steps:

[0065] Such as image 3 As shown, the millet raw flour, millet cooked flour or millet micropowder used in Example 1 were mixed with wheat flour (that is, Shiluan flour), water and salt according to different additions respectively, and then kneaded dough, proofed for 30 minutes, and pressed dough. Finally, the gained noodle strips are cut into 2mm wide noodles and air-dried to obtain vermicelli.

[0066] Wherein, the addition of water is 35% of the total mass of wheat flour, millet cooked powder and millet powder;

[0067] The amount of salt added is 2% of the total mass of wheat flour, millet cooked powder and millet powder.

[0068] The dough kneading steps are: knead the dough slowly for 2 minutes, then knead the dough for 2 minutes quickly, and finally knead the dough for 2 ...

Embodiment 3

[0081] Example 3, sensory evaluation of raw millet flour, cooked flour, and finely powdered dried noodles

[0082] Using the scoring system of 7 members of the group, in the sensory evaluation, the color, surface condition, hardness, toughness, viscosity, palatability, smoothness, and comprehensive evaluation (points) of the dried noodles obtained in Example 2 are scored, and the comprehensive evaluation is drawn. Evaluation score comparison chart.

[0083] The scoring items and score distribution of dried noodles are shown in Table 2: refer to SB / T10137-93, the total score is 100 points, of which: 10 points for color, 10 points for appearance state, 20 points for palatability (soft and hard), 25 points for toughness, and 25 points for stickiness 5 points for smoothness and 5 points for taste.

[0084] Table 2. Vermicelli tasting items and scoring criteria

[0085]

[0086] The result is as Figure 4 shown.

[0087] Figure 4 The content of raw millet powder, cooked mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com