Noise reduction electrode of electrostatic precipitator

An electrostatic precipitator and collecting electrode technology, applied in the field of electrodes, can solve the problems of reduced impedance of the collecting electrode and the repelling electrode, the ignition breakdown of the dust collector, and the dust collection efficiency has not been significantly improved, so as to reduce the impact of the electrostatic precipitator. The probability of fire breakdown damage, the effect of eliminating electrostatic creepage and sparking, and avoiding burr tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

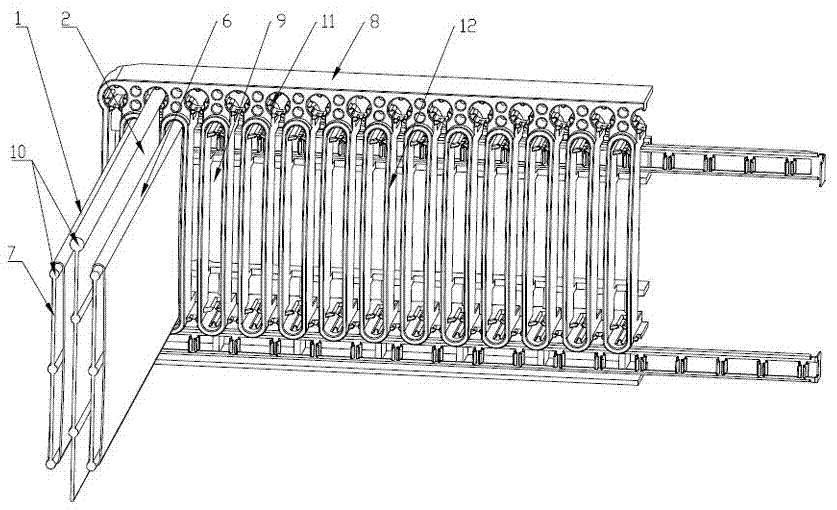

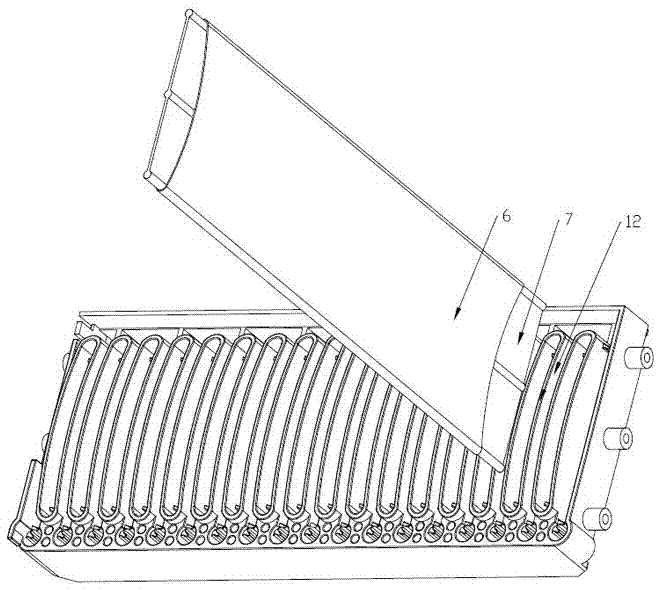

[0029] The invention provides a noise reduction electrode of an electrostatic precipitator, which has good noise reduction effect. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

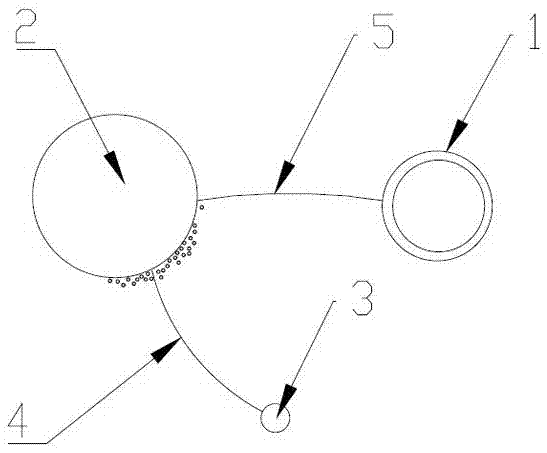

[0030] Such as figure 1 As shown, a noise reduction electrode of an electrostatic precipitator includes a repelling electrode 1, a collecting electrode 2, and a generating electrode 3. The generating electrode can also be called a corona electrode, and a collecting electric field is formed between the generating electrode 3 and the collecting electrode 2. 4. A repelling electric field 5 is formed between the repelling electrode 1 and the collecting electrode 2; the collecting electrode 2 is a conductive plate, and the repelling electrode 1 is a repelling electrode plate coated with an insulating outer layer or a semiconductor outer layer. The specific principle is that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com