Processing system and processing method for manufacturing antibacterial PEVA (polyethylene vinyl acetate) film

A processing method and processing system technology, applied in the field of antibacterial, can solve the problems of low antibacterial efficiency, high cost, large film thickness, etc., and achieve the effect of good antibacterial performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

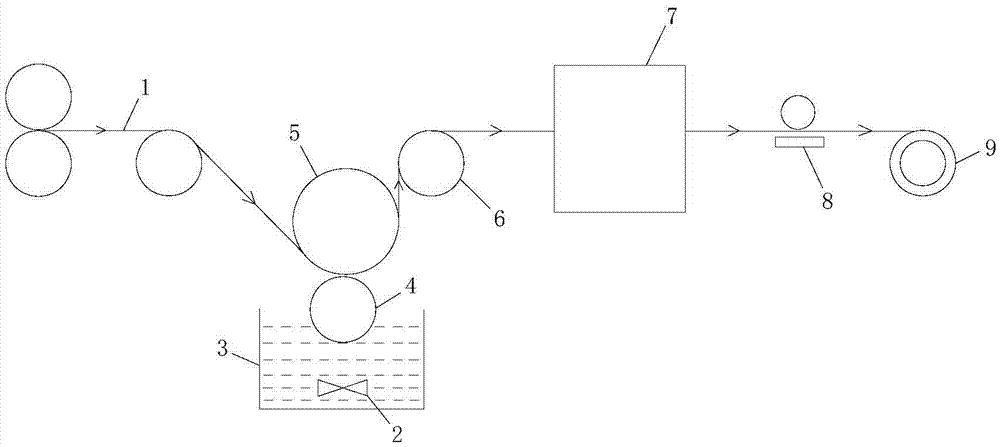

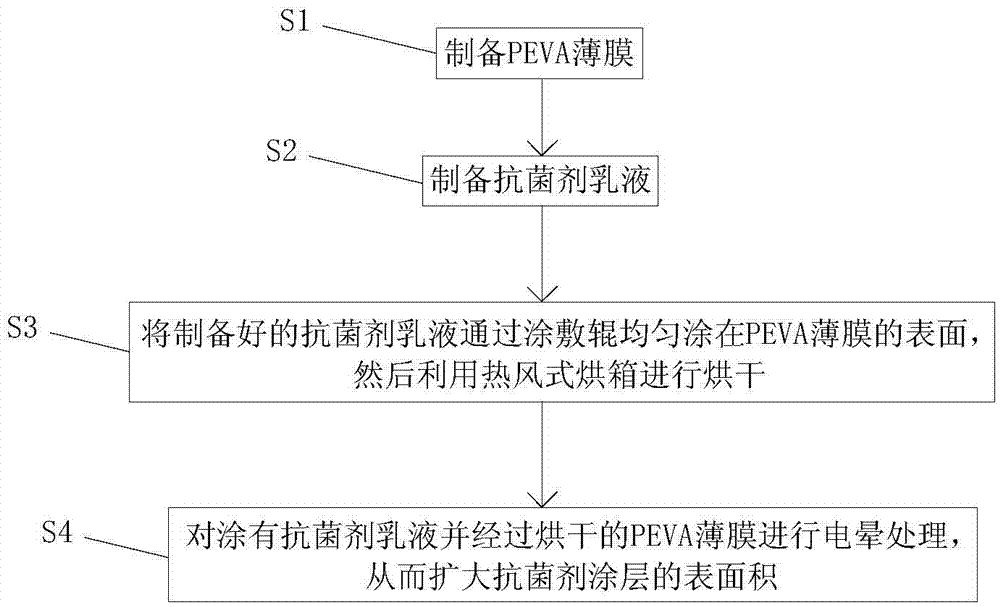

[0028] Such as figure 1 As shown, the present invention describes a processing system for manufacturing antibacterial PEVA film, including PEVA film 1, which passes through turning roller 5, carrier roller 6, hot air oven 7, corona device 8 and winding device 9 successively connected to form a complete delivery system for PEVA film 1.

[0029] Simultaneously, a coating roll 4 is arranged directly below the turning roll 5, and the PEVA film 1 passes through the gap between the turning roll 5 and the coating roll 4, so that the coating roll 4 coats the surface of the PEVA film 1; The bottom of the application roller 4 is immersed in the antibacterial agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com