Ozone water machine using raw material water for cooling

An ozone water machine and raw water technology, which is applied in ozone preparation, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem that cooling water cooling methods are difficult to achieve cooling liquid cooling effect, waste of water resources, large space occupation, etc. problems, to achieve the effect of saving cost and space, avoiding waste and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

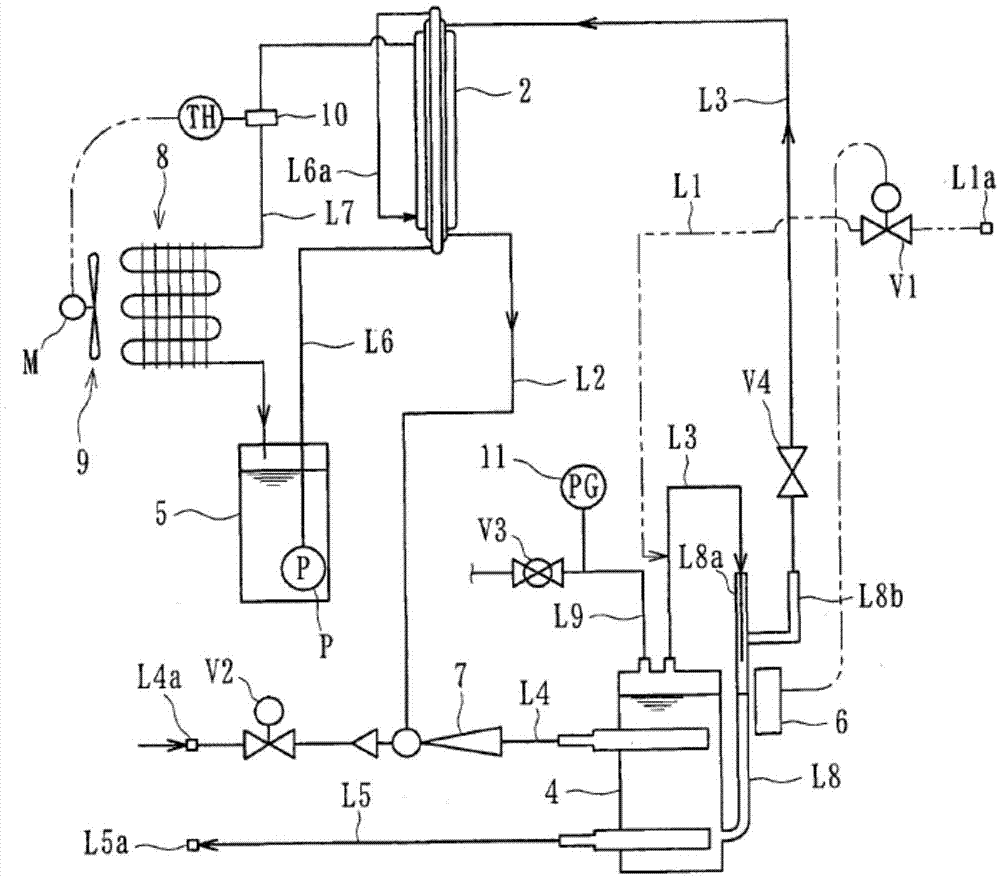

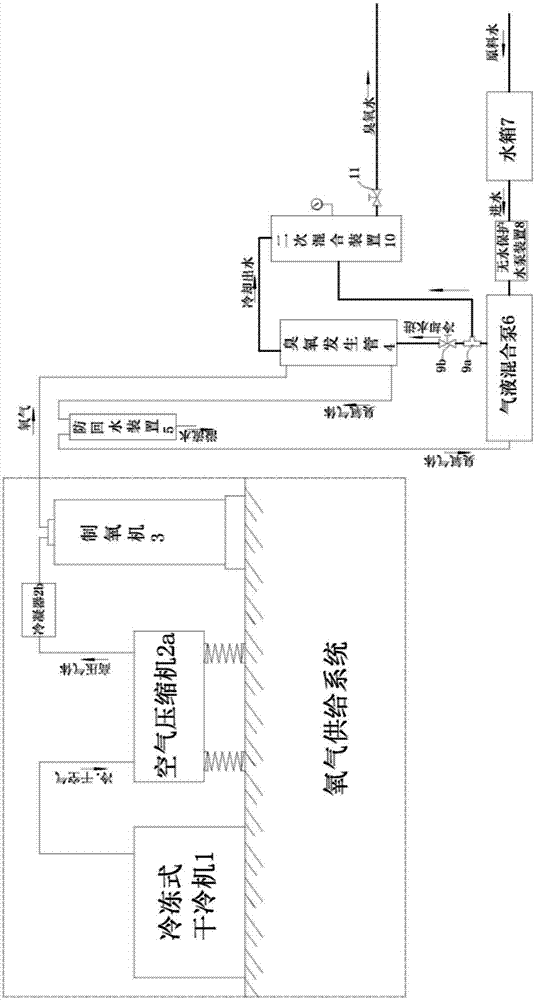

[0038] Such as Figure 2 to Figure 8 As shown, the ozone water machine of Embodiment 1 of the present invention includes an oxygen supply system, a water-cooled ozone generating tube 4, an anti-backwater device 5, a gas-liquid mixing pump 6, a water tank 7 for storing raw water, and an anhydrous protection device 8. The shunt pipeline, the ozone dissolving device 10, the control circuit board 12 and the vertical cabinet 13 for controlling the operation of the ozone water machine, wherein the anti-backwater device 5 is provided with an air inlet, an air outlet and an overflow port 5a, The anti-backwater device 5 can output the gas input from the air inlet through the air outlet and discharge the liquid flowing backward from the air outlet through the overflow port; the ozone dissolving device 10 is provided with a first water inlet and a second water inlet.

[0039] Above-mentioned oxygen supply system comprises refrigerated dryer 1, air compressor 2a, condenser 2b and oxygen g...

Embodiment 2

[0049] Such as Figure 9 As shown, the ozone water machine of Embodiment 2 of the present invention is basically the same as Embodiment 1, and their difference is that in Embodiment 2, the ozone dissolving device 10 is provided with a first water inlet and a second water inlet, and the shunt pipeline includes The second three-way joint 9c and the second flow regulating valve 9d, the second three-way joint 9c has the straight-through water inlet that the pipe diameter is adapted to the water outlet of the gas-liquid mixing pump 6, and the pipe diameter is adapted to the first of the ozone dissolving device 10 The straight-through water outlet of a water inlet and the pipe diameter are adapted to the bypass water outlet of the cooling water inlet of the water-cooled ozone generating tube 4; The straight-through water outlet is connected to the first water inlet of the ozone dissolving device 10 through the second flow regulating valve 9d, and the bypass water outlet is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com