Method for preparing nano particles

A carbon nanoparticle, carbon material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as high cost and complex process, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Transfer 0.5g of graphene to a KOH solution with a concentration of 1mol / L, heat at 80°C for 2h, then cool to room temperature naturally, filter, rinse with distilled water 3 times, and dry naturally; mix 3mg of CaO with 2mg of graphene Finally, add 1mL of distilled water, grind for 10min, and then dry naturally; transfer the obtained sample to a container, add 5mL of distilled water, sonicate in an ultrasonic instrument with a power of 80W for 5h, filter, and dry naturally to obtain a super carbon nanoparticles.

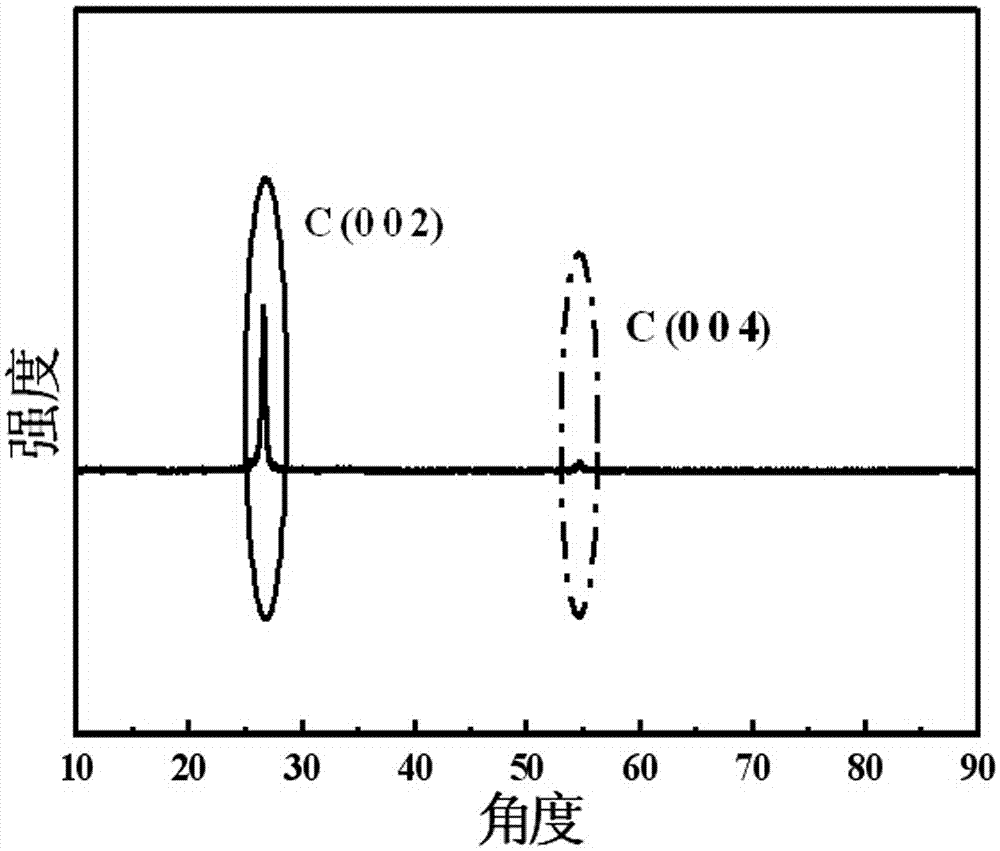

[0022] figure 1 It is the XRD spectrum pattern of the carbon nanoparticles prepared in Example 1. Sharp diffraction peaks of the (002) crystal plane of C and the crystal plane of C (004) appear in the figure, and no other miscellaneous peaks appear. It shows that the crystal structure of the prepared carbon nanomaterials is intact and has a high degree of crystallinity.

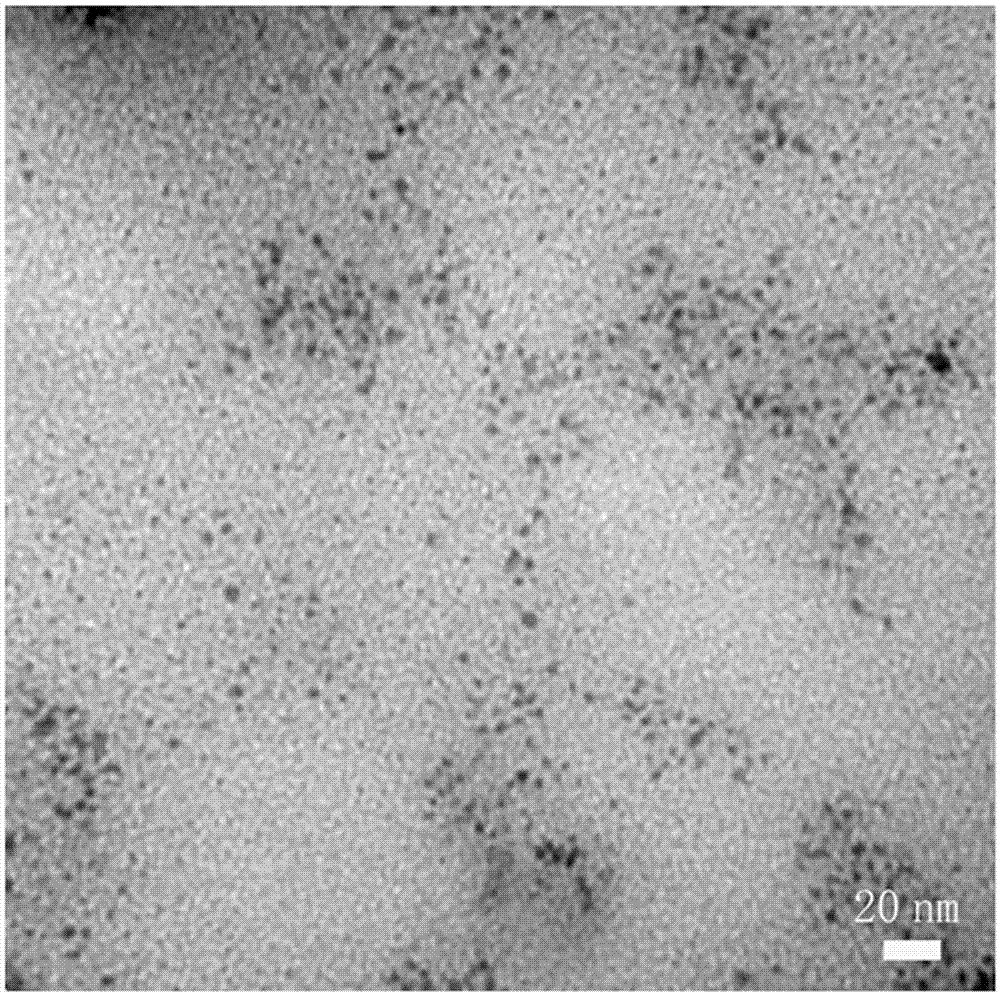

[0023] figure 2 The TEM photo of the carbon nanomaterial sample prepared in Example...

Embodiment 2

[0025] Move the mixture of 1.0g of carbon black and graphene into a KOH solution with a concentration of 1.5mol / L, heat at 95°C for 3h, then cool to room temperature naturally, filter, rinse with distilled water 4 times, and dry naturally; After mixing 5 mg of PdO with 2 mg of carbon mixture, add 1.5 mL of distilled water, grind for 10 min, and then dry it naturally; transfer the obtained sample to a container, add 4.5 mL of distilled water, and sonicate for 4.5 h in an ultrasonic instrument with a power of 80W. Filter and dry naturally to obtain super carbon nanoparticles. The particle size of the obtained carbon nanoparticles is about 2 nanometers.

Embodiment 3

[0027] Move 1.2g of acetylene black into NaOH solution with a concentration of 0.5mol / L, heat at 75°C for 3h, then cool to room temperature naturally, filter, rinse with distilled water 5 times, and dry naturally; treat 5mgPdO with 2mg acetylene black, then add 1.8mL of distilled water, grind for 15min, and then dry naturally; transfer the obtained sample to a container, then 3.0mL of distilled water, sonicate in an ultrasonic instrument with a power of 90W for 6h, filter, and let it dry naturally Dry to get super carbon nanoparticles. The prepared carbon nanoparticles have a particle size of about 2 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com