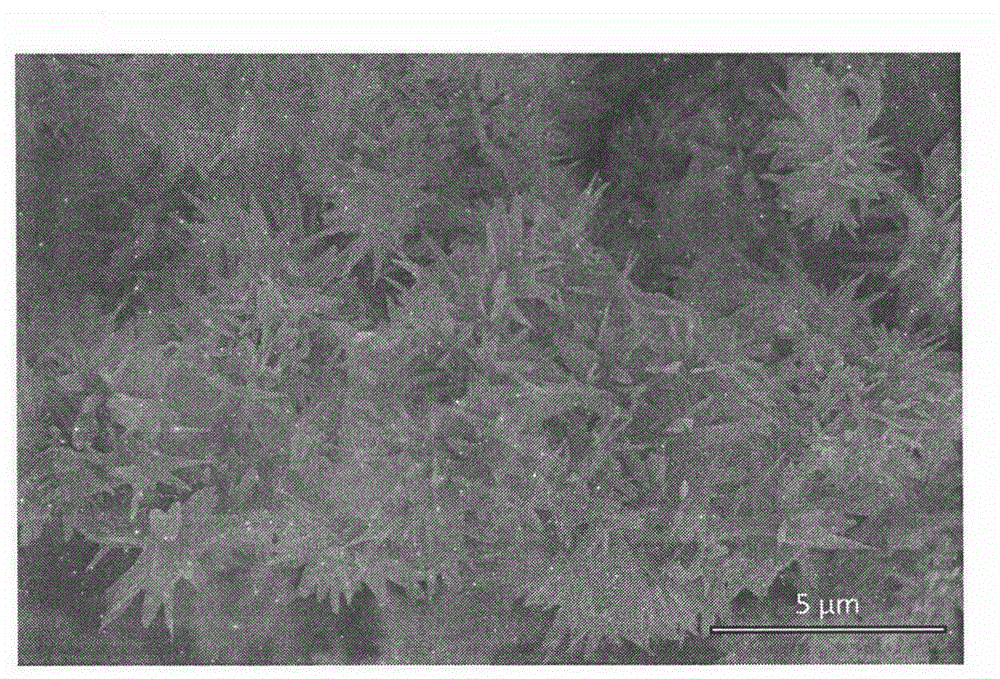

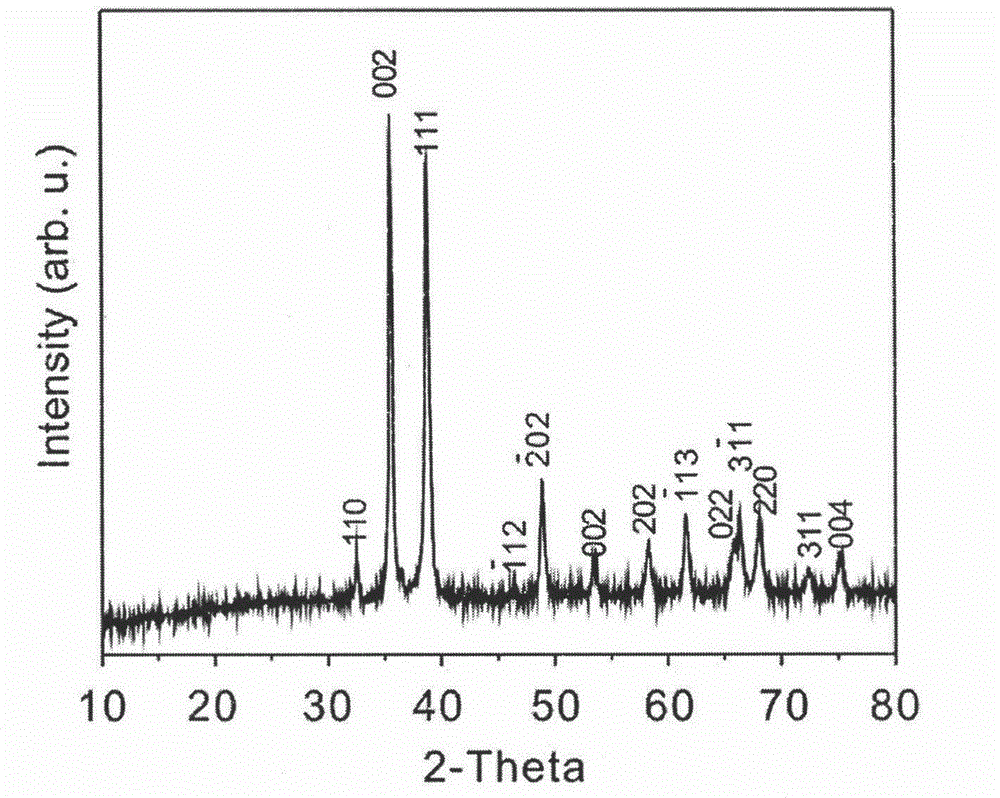

Method for preparing pompon-like copper oxide

A copper oxide, spherical technology, applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of time-consuming and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] ① Weigh copper sulfate pentahydrate (CuSO 4 ·5H 2 (0) 2.6g, take 15ml of polyethylene glycol (PEG), add 120ml of distilled water, place at 25°C, and stir electromagnetically for 10min to obtain liquid A.

[0018] ②Weigh 5.0g of sodium hydroxide (NaOH) and 15g of urea, dissolve in 100ml of distilled water, place at 25°C, and stir electromagnetically for 5min to obtain liquid B.

[0019] ③ Weigh 65ml of solution B, add it to 120ml of solution A under stirring condition, place it at 25°C, and stir it with electromagnetic for 15min to obtain blue solution C.

[0020] ④ Take 10ml of liquid C and put it into a 25-50ml reaction kettle, place the reaction kettle in a microwave environment, and keep the temperature at 180°C for 25 minutes.

[0021] ⑤ Wash the black solid product obtained in the reaction kettle with distilled water for 3 times, and then with an organic solvent for 3 times, and keep the product at 30°C for 12 hours to dry.

Embodiment 2

[0023] ① Weigh copper sulfate pentahydrate (CuSO 4 ·5H 2 (0) 2.6g, take 15ml of polyethylene glycol (PEG), add 120ml of distilled water, place at 25°C, and stir electromagnetically for 10min to obtain liquid A.

[0024] ②Weigh 5.0g of sodium hydroxide (NaOH) and 15g of urea, dissolve in 100ml of distilled water, place at 25°C, and stir electromagnetically for 5min to obtain liquid B.

[0025] ③ Weigh 65ml of solution B, add it to 120ml of solution A under stirring condition, place it at 25°C, and stir it with electromagnetic for 15min to obtain blue solution C.

[0026] ④ Take 10ml of liquid C and put it into a 25-50ml reaction kettle, place the reaction kettle in a microwave environment, and keep the temperature at 180°C for 5 minutes.

[0027] ⑤ Wash the black solid product obtained in the reaction kettle with distilled water for 3 times, and then with an organic solvent for 3 times, and keep the product at 30°C for 12 hours to dry.

Embodiment 3

[0029] ① Weigh copper sulfate pentahydrate (CuSO 4 ·5H 2 (0) 2.6g, take 15ml of polyethylene glycol (PEG), add 120ml of distilled water, place at 25°C, and stir electromagnetically for 10min to obtain liquid A.

[0030] ②Weigh 5.0g of sodium hydroxide (NaOH) and 15g of urea, dissolve in 100ml of distilled water, place at 25°C, and stir electromagnetically for 5min to obtain liquid B.

[0031] ③ Weigh 65ml of solution B, add it to 120ml of solution A under stirring condition, place it at 25°C, and stir it with electromagnetic for 15min to obtain blue solution C.

[0032] ④ Take 10ml of liquid C and put it into a 25-50ml reaction kettle, place the reaction kettle in a microwave environment, and keep the temperature at 180°C for 10 minutes.

[0033] ⑤ Wash the black solid product obtained in the reaction kettle with distilled water for 3 times, and then with an organic solvent for 3 times, and keep the product at 30°C for 12 hours to dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com