A method for removing hexavalent chromium in solution by marine Aspergillus niger

A marine Aspergillus niger, hexavalent chromium technology, applied in the directions of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of non-recyclable use, high cost, small adsorption capacity of Aspergillus niger spores, etc. To achieve the effect of controllable size, convenient preparation and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the cultivation of Aspergillus niger mycelium ball

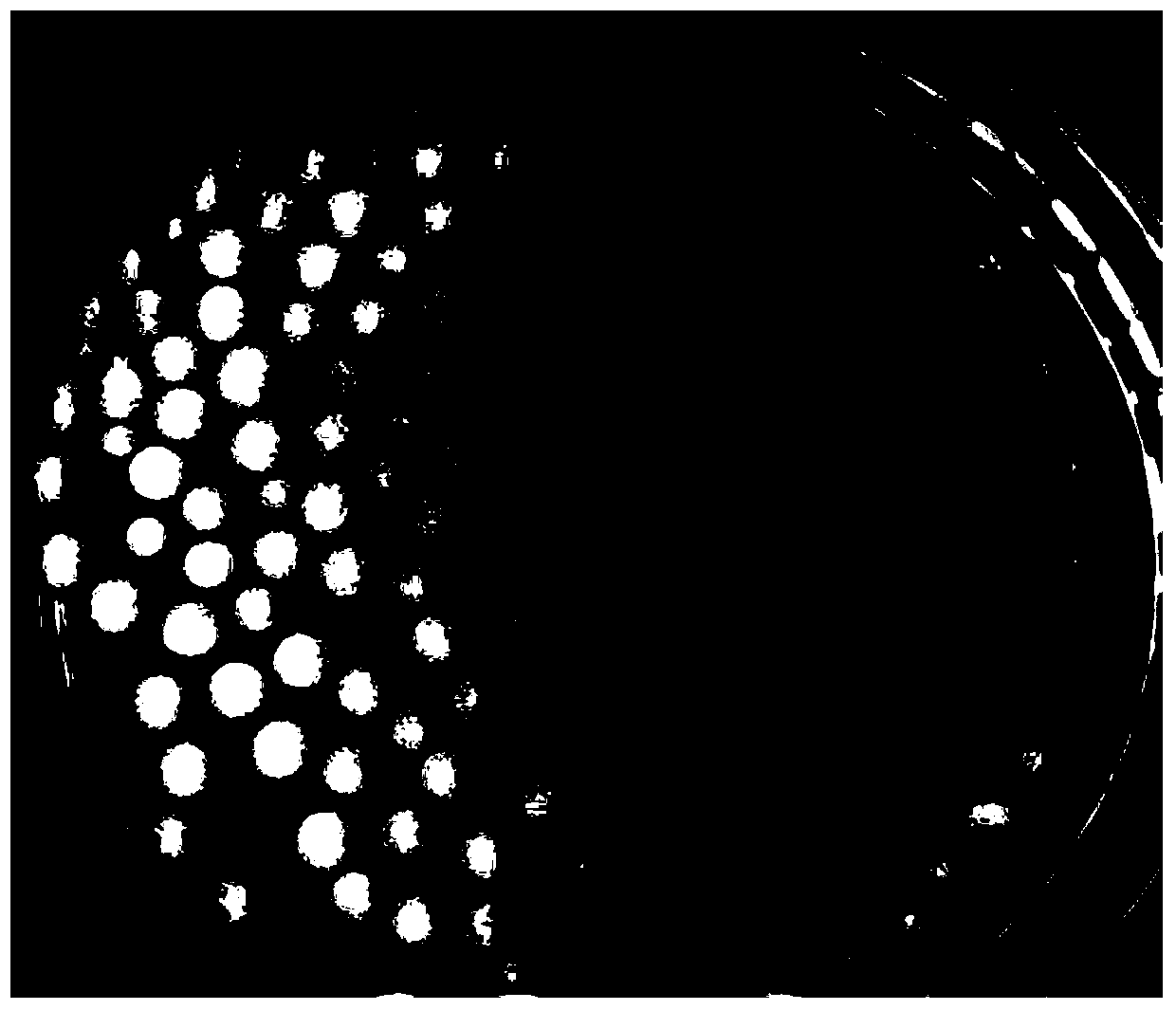

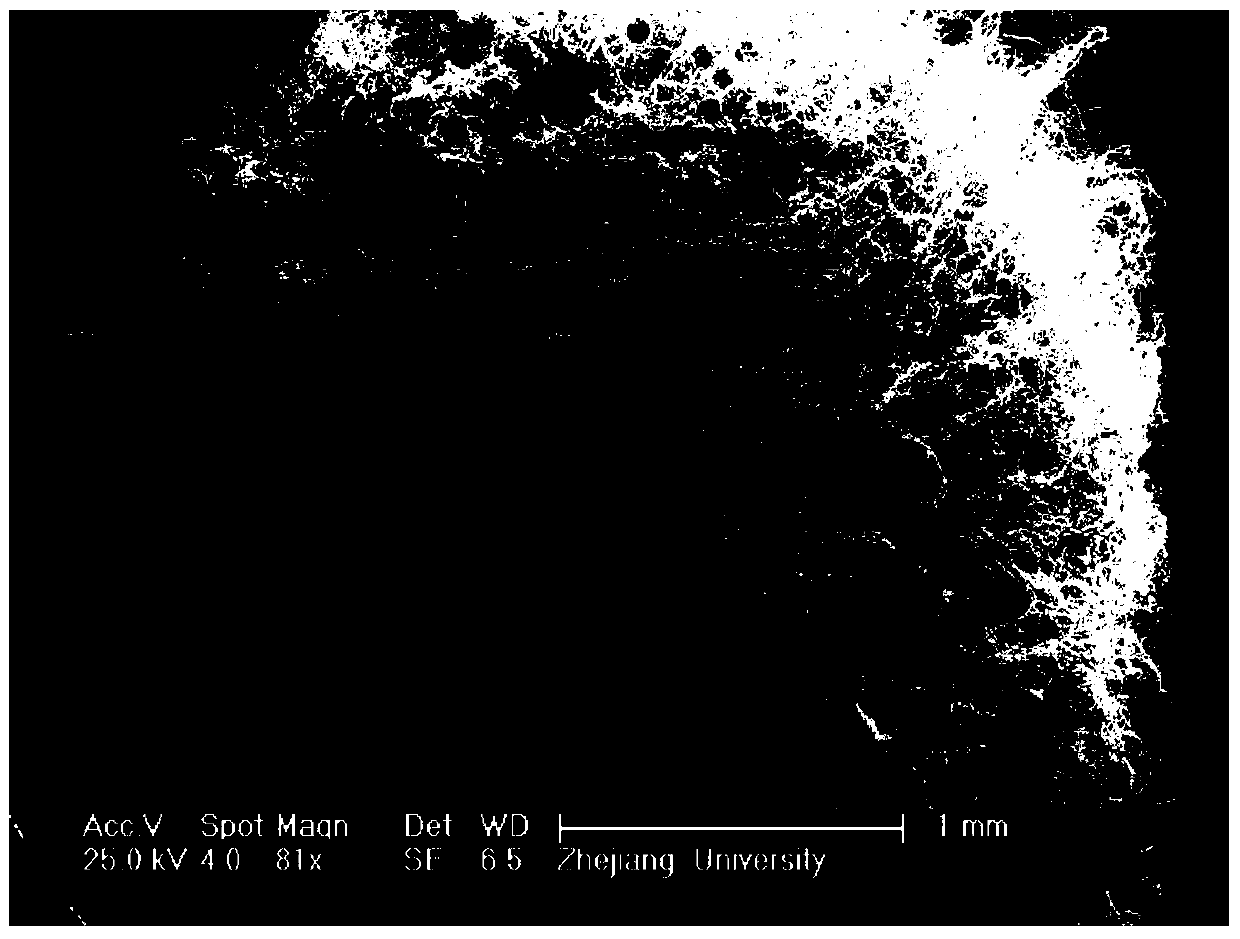

[0030] Inoculate marine Aspergillus niger on PDA medium (potato 200g / L, glucose 20g / L, agar 17g / L), place it in a constant temperature incubator (25°C) and cultivate it for 3 days, take a certain amount of spores and inoculate it into the preparation culture base (glucose 10g / L, NH 4 Cl2g / L, KH 2 PO 4 2g / L, MgSO 4 0.5g / L, yeast extract powder 2g / L), in constant temperature 25 ℃ and the shaker of rotating speed 100 revs / min, constant temperature culture 60 hours, form the substantially uniform aspergillus niger mycelial ball of size. Collect aspergillus niger mycelia ball, its overall appearance is as follows figure 1 Shown are untreated wet mycelium balls. The mycelial balls of Aspergillus niger were of uniform size and good spherical shape, and the shape remained unchanged after freeze-drying. The specific particle size of Aspergillus niger mycelium balls can be obtained by statistics, and its a...

Embodiment 2

[0032] Embodiment 2: the cultivation of aspergillus niger mycelium ball

[0033] Inoculate marine Aspergillus niger on PDA medium (potato 180g / L, glucose 18g / L, agar 15g / L), place it in a constant temperature incubator (25°C) and cultivate it for 4 days, take a certain amount of spores and inoculate it into the preparation culture base (glucose 8g / L, NH 4 Cl1.8g / L, KH 2 PO 4 1.8g / L, MgSO 4 0.4g / L, yeast extract powder 1.8g / L), in constant temperature 25 ℃ and the shaker of rotating speed 50 revs / min, constant temperature culture 48 hours, form the substantially uniform Aspergillus niger mycelial ball of size. The aspergillus niger mycelia balls were taken out, washed twice with water, aged in clear water for 10 hours to form a biological water treatment agent that can be used to remove hexavalent chromium.

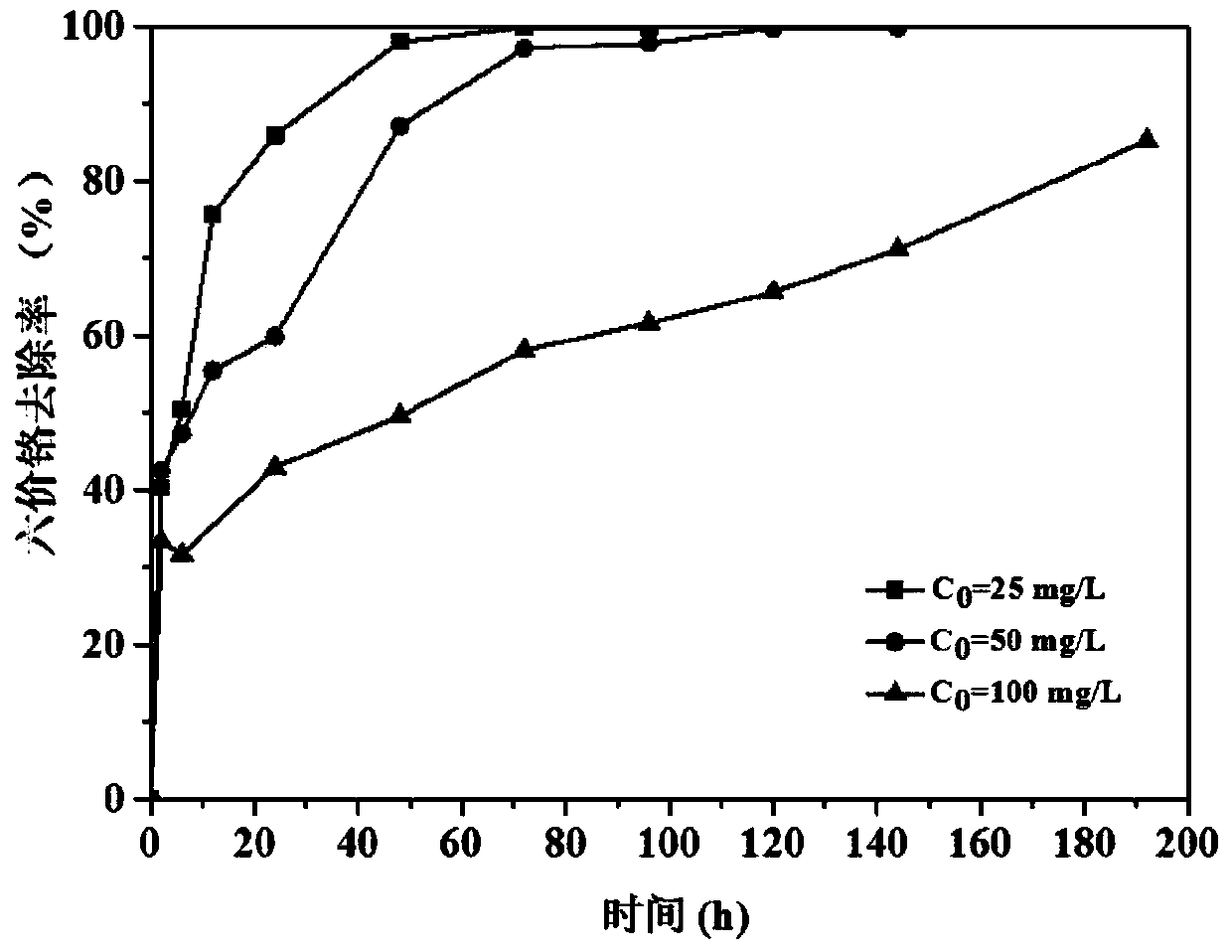

[0034]The prepared biological water treatment agent is directly added to the wastewater containing hexavalent chromium, and is fully mixed by mechanical stirring for...

Embodiment 3

[0035] Embodiment 3: the cultivation of Aspergillus niger mycelium ball

[0036] Inoculate marine Aspergillus niger on PDA medium (potato 220g / L, glucose 22g / L, agar 20g / L), place it in a constant temperature incubator (30°C) and cultivate it for 5 days, take a certain amount of spores and inoculate it into the preparation culture base (glucose 12g / L, NH 4 Cl2.2g / L, KH 2 PO 4 2.2g / L, MgSO 4 0.6g / L, yeast extract powder 2.2g / L), in constant temperature 30 ℃ and the shaker of rotating speed 200 revs / min, constant temperature culture 72 hours, form the substantially uniform Aspergillus niger mycelial ball of size. The Aspergillus niger mycelia balls were taken out, washed twice with water, placed in clear water and aged for 24 hours to form a biological water treatment agent that can be used to remove hexavalent chromium.

[0037] Add the prepared biological water treatment agent directly into the wastewater containing hexavalent chromium, and use a fluid pump to circulate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com