Integrated sludge solidification device

A sludge solidification and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of unreasonable arrangement of solidification devices, difficult recovery of groundwater resources, occupation of land resources, etc., achieving a high degree of automation, Low processing cost and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

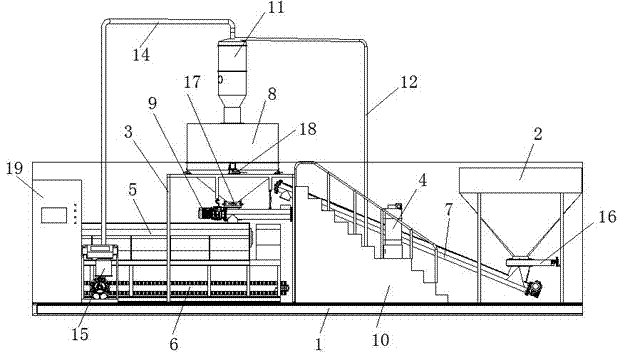

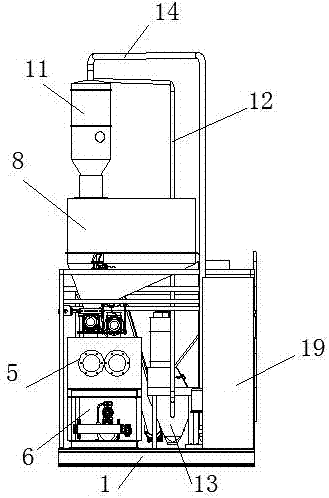

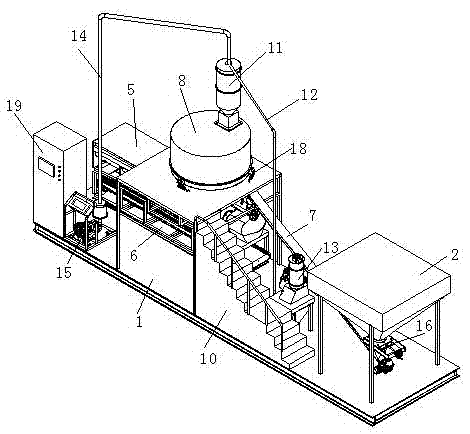

[0016] Embodiment 1: an integrated sludge solidification device, including a base 1, a sludge silo 2 provided on the right side of the base 1, a curing agent silo platform 3 arranged in the middle of the base 1, and a sludge silo 2 and the bag unloading station platform 4 between the solidifying agent silo platform 3, a biaxial horizontal mixer 5 is arranged below the solidifying agent silo platform 4, and a belt conveyor 6 is arranged below the biaxial horizontal mixer 5, and the The discharge port at the bottom of the sludge silo 2 is connected to the first screw conveyor 7 inclined upwards, the feed port of the first screw conveyor 7 is connected to the discharge port at the bottom of the sludge silo 2, and the platform 3 of the curing agent silo A curing agent silo 8 is provided, and a second screw conveying shaft 9 is arranged below the curing agent silo 8. The feed port of the second screw conveying shaft 9 is connected to the discharge port at the bottom of the curing ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com