Fluorescent polyurethane emulsion based on diketopyrrolopyrrole derivative

A polyurethane emulsion and fluorescence technology, which is applied in the field of fluorescent polyurethane emulsion, can solve the problems of weak fluorescence intensity of fluorescent urethane emulsion, low molecular weight of fluorescent urethane emulsion, and narrow application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]

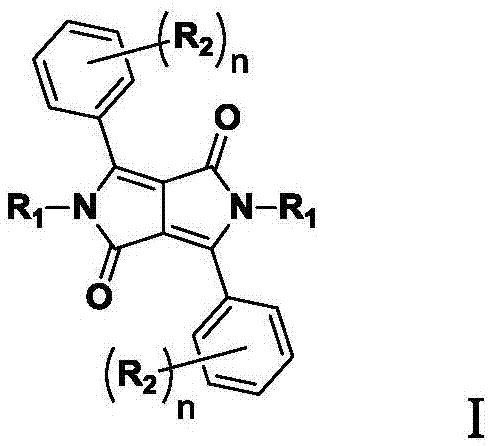

[0039] (1) Under the protection of dry nitrogen, place 0.0001mol of the compound shown in formula Ia and 15mol of dehydrated diphenylmethane diisocyanate (MDI) in a reactor with a temperature control device and a stirring device, stir and heat up to 60°C-80°C, keep in this state for 6 hours, cool, and dry to constant weight to obtain mixture a;

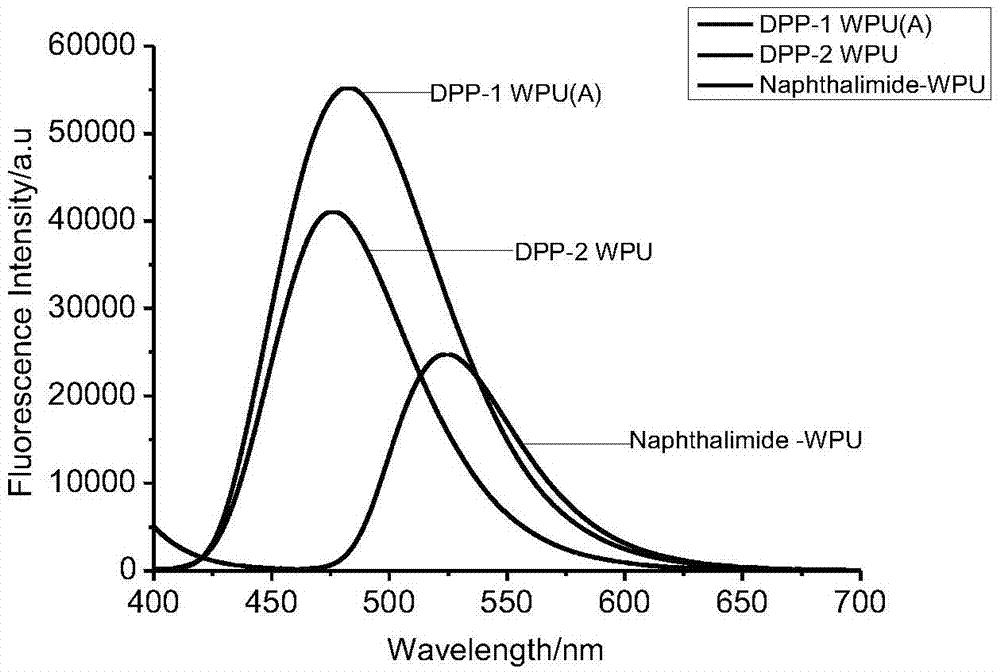

[0040] (2) Add 2 mol of polypropylene glycol (Mw=500 to 3,000), 1 mol of 2,2-dimethylol propionic acid (DMPA), 1.5 mol of 1,4-butanediol and 0.001 mol of 0.2% dibutyltin dilaurate (Catalyst) added to the reaction with the above mixture a, stirred at 20°C to 30°C for 2 hours to 7 hours, then added 5mol triethanolamine to the reactor and stirred at 60°C to 70°C for at least 30 minutes, then added Stir and emulsify with water to obtain the target substance (abbreviated as "DPP-1WPU(A)"), whose fluorescence spectrum is shown in figure 1 ..

Embodiment 2

[0042]

[0043] (1) Under the protection of dry nitrogen, 0.001mol of the compound shown in formula Ib and 0.8mol of toluene-2,4-diisocyanate (TDI) after dehydration are placed in a reactor with a temperature control device and a stirring device, Stir and heat up to 60°C to 80°C, keep in this state for 6 hours, cool, and dry to constant weight to obtain mixture b;

[0044] (2) Add 0.1mol polypropylene glycol (Mw=500~3,000), 0.01mol DMPA, 1mol pentylene glycol and 0.076mol of 0.2% dibutyltin dilaurate (catalyst) to the reaction with the above mixture b, at 20°C Stir at ~30°C for 2 hours to 7 hours, then add 5mol triethylamine to the reactor and stir at 60°C to 70°C for at least 30 minutes, then add water to stir and emulsify to obtain the target product (abbreviated as "DPP-2WPU ”), and its fluorescence spectrum is shown in figure 1 ..

Embodiment 3

[0046]

[0047] (1) Under the protection of dry nitrogen, place 0.01mol of the compound shown in formula Ic and 3.8mol of MDI dehydrated in a reactor with a temperature control device and a stirring device, stir and heat up to 60°C to 80°C, and This state was maintained for 6 hours, cooled, and dried to constant weight to obtain a mixture c;

[0048] (2) 18mol polyethylene glycol (Mw=500~3,000), 1.8molDMPA, 35mol glycerol and 2.023mol of 0.2% dibutyltin dilaurate (catalyst) are added to the reaction of the above mixture c, 20 Stir at ℃~30℃ for 2 hours~7 hours, then add 6mol triethylamine to the reactor and stir at 60℃~70℃ for at least 30 minutes, then add water to stir and emulsify to obtain the target product (abbreviated as "DPP- 3WPU").

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com