Gravure water-based ink for ivory board and printing method

A technology of water-based ink and printing method, applied in the direction of ink, application, household appliances, etc., can solve the problems of poor film-forming effect, slow volatilization, low adhesion and easy falling off of the ink layer, and achieve good printing effect and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

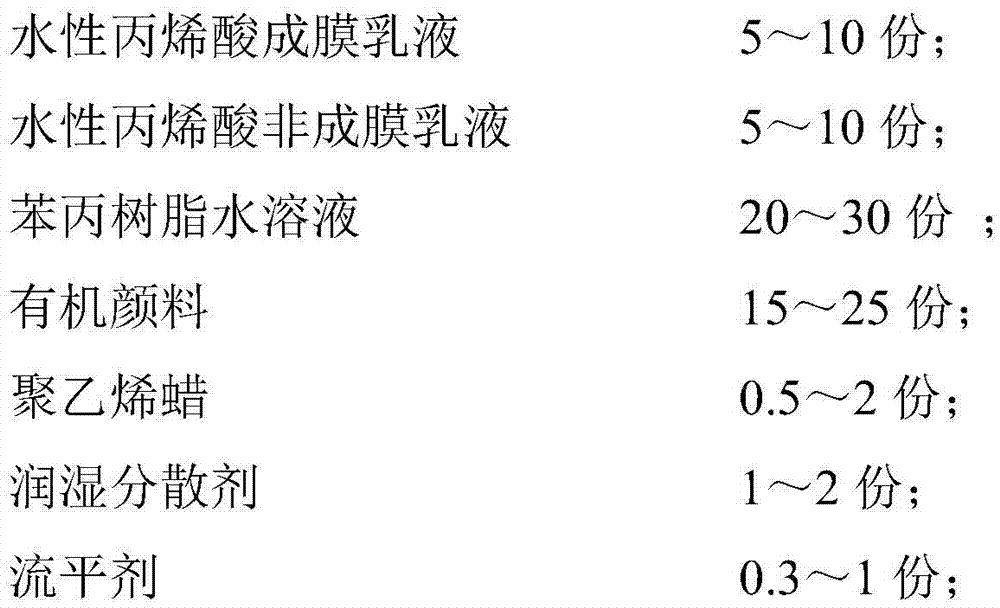

[0037] 【formula】

[0038]

[0039] The water-based acrylic film-forming emulsion (purchased from DSM Coating Resin Co., Ltd.) has characteristics: a polymer emulsion of water-based acrylic acid with a pH value of about 7.5, a solid content of 48%, a Tg value of about 21°C, and an acid value of 50 mgKOH / g , Ultra-low VOC content.

[0040] The water-based acrylic non-film-forming emulsion (purchased from DSM Coating Resin Co., Ltd.) has characteristics: a styrene with a pH value of about 7.5, a solid content of 45%, a Tg value of about 100°C, and an acid value of 80 mgKOH / g And acrylic polymer emulsion, ultra-low voc content.

[0041] Described styrene-acrylic resin aqueous solution is prepared by following method:

[0042] Add 35% styrene-acrylic solid resin and 65% deionized water into the reactor, heat up to 55°C, and add the pH regulator diethanolamine while stirring, so that the pH value of the solution in the reactor is always maintained at About 8.5 (the consumption...

Embodiment 2

[0057] 【formula】

[0058]

[0059]

[0060] The water-based acrylic film-forming emulsion, water-based acrylic non-film-forming emulsion, styrene-acrylic resin aqueous solution, and polyethylene wax are all the same as the relevant raw materials in Example 1.

[0061] The organic pigment is P.R.48:2 primary red, which is purchased from Clariant Pigment Company. Features: water-based organic pigment, light fastness level 6, PH value 7.5-8.0, heat resistance 180°C, oil absorption 45-55, bright and saturated color good degree.

[0062] As the wetting and dispersing agent, high molecular weight copolymer SMART9420 dispersant (purchased from Guangzhou Fengshuo Chemical Company) was selected for use.

[0063] As the leveling agent, diester sulfosuccinate OT75 surfactant (purchased from Huanqi Chemical Company) was selected for use.

[0064] PH regulator, select AMP-95 (purchased from Dow Chemical Company) for use.

[0065] Defoamer, select BYK094 organosilicon defoamer (purch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com