A gasification method for co-feeding residual oil, dry powder and coal-water slurry

A technology of coal-water slurry and residual oil, which is applied to the gasification field where residual oil, dry powder and coal-water slurry are fed together, can solve the problems of reduced coal gasification efficiency, singleness, and difficulty in increasing the concentration of coal-water slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

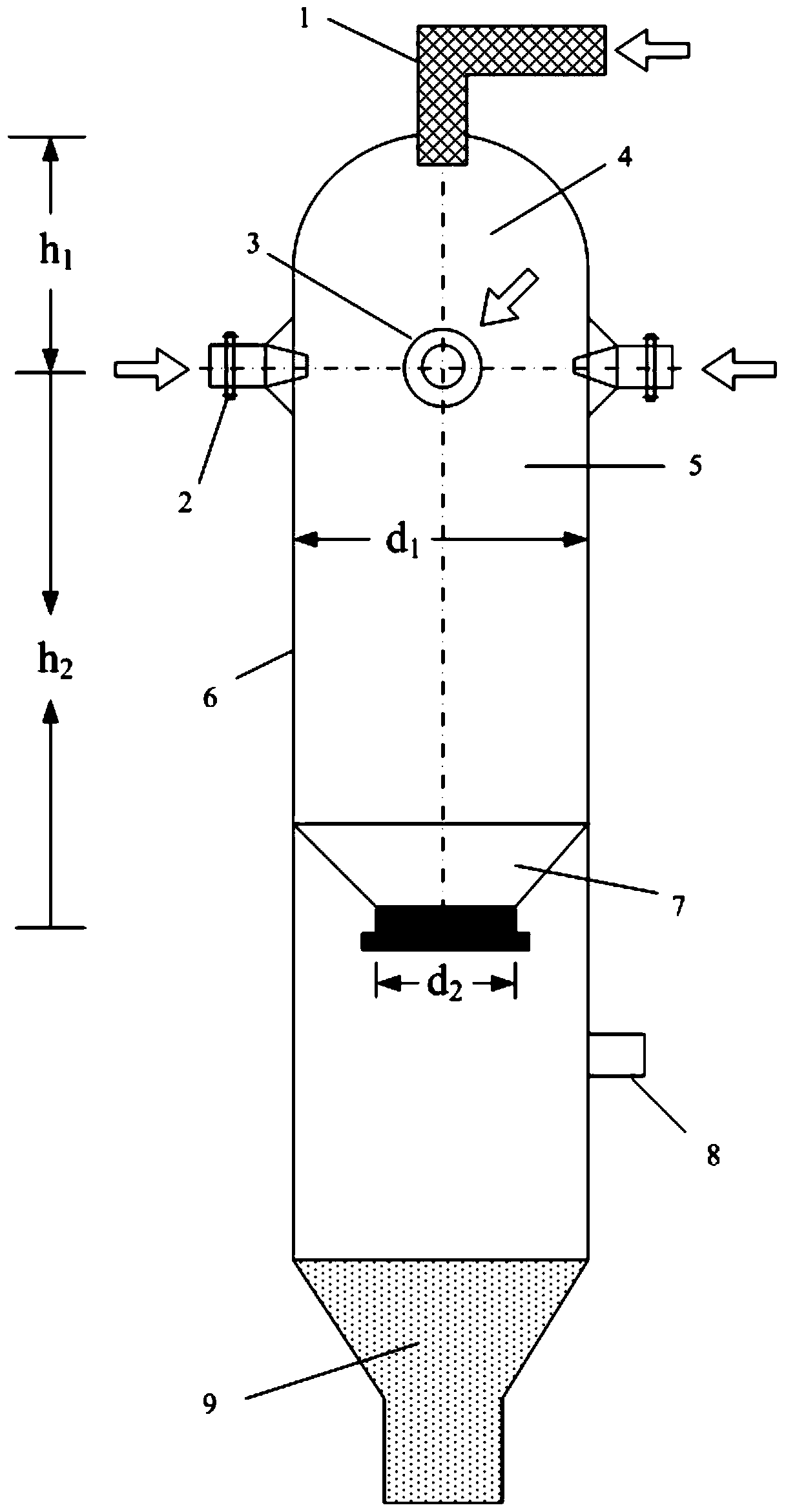

[0048] This example is used to illustrate the gasification method for co-feeding the residual oil, dry powder and coal-water slurry provided by the present invention.

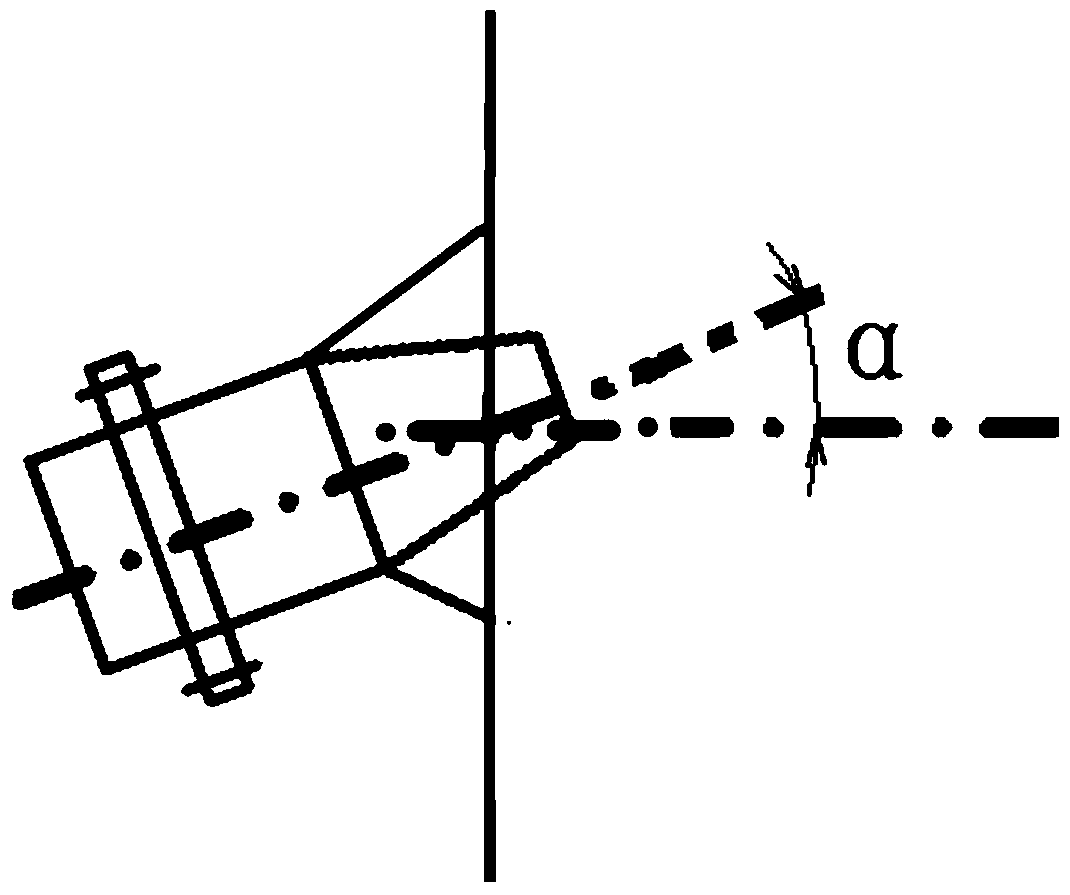

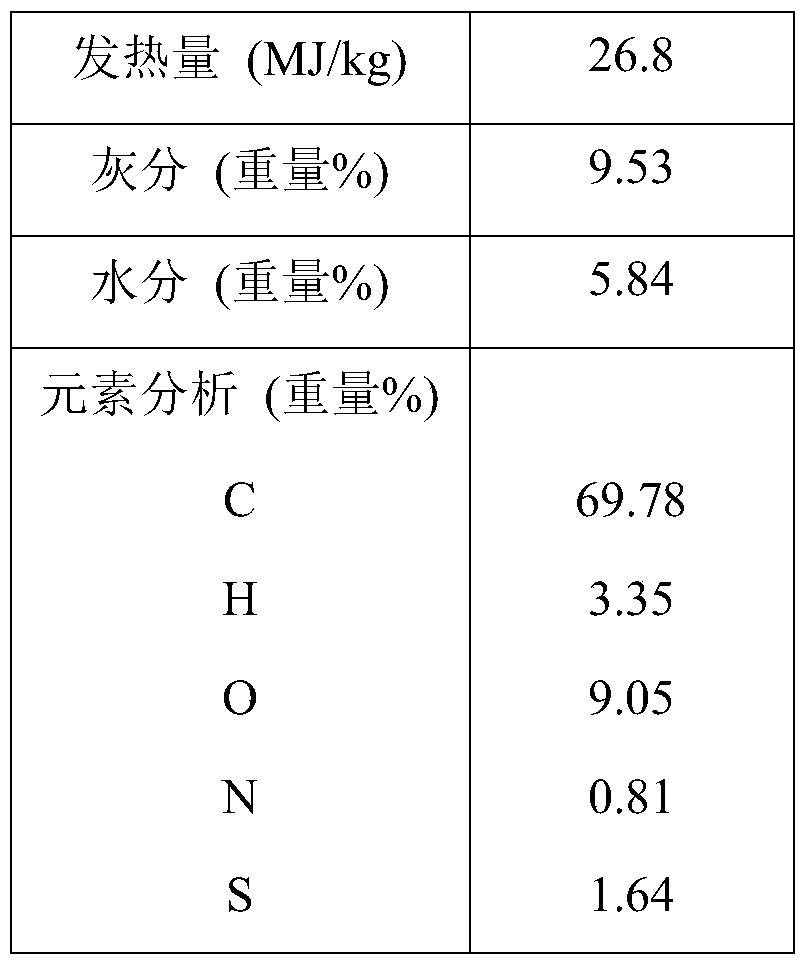

[0049] The ash content of the residual oil is 27.33%, and its composition is shown in Table 2. The residual oil is transported by steam, and the steam-oil ratio is about 0.41. The solid content of the coal water slurry is 50% by weight, and the average particle size of the solid particles is 71 μm. The speeds of the coal water slurry and residual oil are about 10 m / s and 8.9 m / s respectively, and enter the opposite side nozzles respectively. The speed of the gasification agent (oxygen) entering the furnace is about 100m / s. The type of coal used in dry pulverized coal is the same as that used in coal-water slurry, and its composition is shown in Table 1. The ground dry coal powder (average particle size is 65 μm) is passed through a small amount of N 2 Conveying, the conveying density is about 400kg / m 3 . Th...

Embodiment 2

[0062] This example is used to illustrate the gasification method for co-feeding the residual oil, dry powder and coal-water slurry provided by the present invention.

[0063] The dry powder is prepared by mixing dry coal powder (the same as that in Example 1) and petroleum coke powder at a mass ratio of about 1:1. The ash content of petroleum coke is 0.86%. The composition is shown in Table 5. The ground dry powder (average particle size is 70μm) is passed through N 2 Conveying, the conveying density is about 400kg / m 3 . Its feed rate is about 14t / h. The ash content of the residual oil is 27.33%, and its composition is shown in Table 2. The residual oil is transported by steam, and the steam-oil ratio is about 0.41. The solid content of the coal water slurry is 50%, and the solid particle size is 75 μm, and its composition is shown in Table 1. The inlet velocities of coal water slurry and residual oil are about 10.2m / s and 10.4m / s respectively, and they enter the opposite...

Embodiment 3

[0069] This example is used to illustrate the gasification method for co-feeding the residual oil, dry powder and coal-water slurry provided by the present invention.

[0070] The dry powder is petroleum coke powder with an ash content of 0.86%, and its composition is shown in Table 5. The ground petroleum coke powder (average particle size is 75μm) is passed through N 2 Conveying, the conveying density is about 400kg / m 3 . Its feed rate is about 14t / h. The ash content of the residual oil is 27.33%, and its composition is shown in Table 2. The residual oil is transported by steam, and the steam-oil ratio is about 0.41. The solid content of the coal water slurry is 50%, and the average particle size of the solid particles is 72 μm, and its composition is shown in Table 1. The inlet velocities of coal water slurry and residual oil are about 8.9m / s and 9.2m / s respectively, and they enter the opposite side nozzles respectively. The speed of the gasification agent (oxygen) ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com