Preparation process and treatment system for papermaking wood flour

A technology of preparation process and treatment system, applied in the field of preparation process and treatment system of wood powder for papermaking, can solve the problems of reduced binding force, high cost of wood powder, and high quality requirements of wood powder, so as to reduce quality requirements and reduce secondary The effect of pollution and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

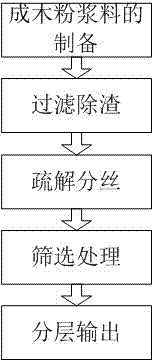

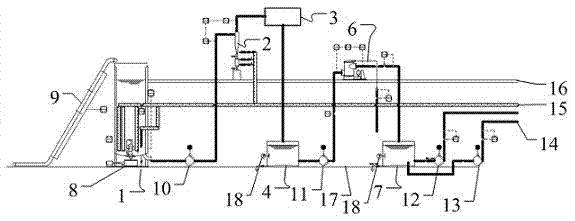

[0032] Such as figure 1 Shown, the invention discloses a kind of preparation technology of wood powder for papermaking, comprises the following steps:

[0033] The first step, the preparation of finished wood flour slurry, select 40-80 mesh wood flour, put 5 parts by mass of wood flour into the preparation tank, add 95 parts by mass of clear water, stir and soak for 20 minutes, and prepare finished wood flour slurry. The wood powder is prepared from coniferous trees and / or broad-leaved trees; the stirring is performed by a hydraulic pulper built in the preparation tank; the wood powder is automatically transported to the preparation tank by a chain plate machine.

[0034] The second step, filter and remove slag, control the mass concentration of the wood powder slurry obtained in the first step to be 3-5%, and transport it to the slag remover by the first pulp pump to filter and remove slag, and obtain the wood powder after removing impurities pulp.

[0035]The third step is...

Embodiment 2

[0039] Such as figure 1 Shown, the invention discloses a kind of preparation technology of wood powder for papermaking, comprises the following steps:

[0040] The first step, the preparation of finished wood flour slurry, select 40-80 mesh wood flour, put 5 parts by mass of wood flour into the preparation tank, add 95 parts by mass of clear water, stir and soak for 20 minutes, and prepare finished wood flour slurry. The wood powder is prepared from coniferous trees and / or broad-leaved trees; the stirring is performed by a hydraulic pulper built in the preparation tank; the wood powder is automatically transported to the preparation tank by a chain plate machine.

[0041] The second step, filter and remove slag, control the mass concentration of the wood powder slurry obtained in the first step to be 3-5%, and transport it to the slag remover by the first pulp pump to filter and remove slag, and obtain the wood powder after removing impurities pulp.

[0042] The third step i...

Embodiment 3

[0046] Such as figure 1 Shown, the invention discloses a kind of preparation technology of wood powder for papermaking, comprises the following steps:

[0047] The first step, the preparation of finished wood flour slurry, select 40-80 mesh wood flour, put 5 parts by mass of wood flour into the preparation tank, add 95 parts by mass of clear water, stir and soak for 20 minutes, and prepare finished wood flour slurry. The wood powder is prepared from coniferous trees and / or broad-leaved trees; the stirring is performed by a hydraulic pulper built in the preparation tank; the wood powder is automatically transported to the preparation tank by a chain plate machine.

[0048] The second step, filter and remove slag, control the mass concentration of the wood powder slurry obtained in the first step to be 3-5%, and transport it to the slag remover by the first pulp pump to filter and remove slag, and obtain the wood powder after removing impurities pulp.

[0049] The third step i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com