Concrete tubular pile still kettle residual air recovery system

A technology for concrete pipe piles and recycling systems, applied in fixed tubular conduit assemblies, heat exchanger types, lighting and heating equipment, etc. Thermal Efficiency, Lower Manufacturing Costs, Higher Temperature Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

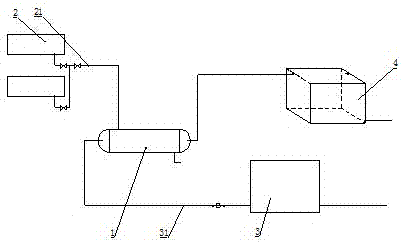

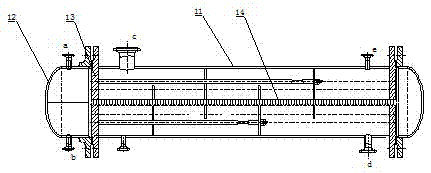

[0012] Such as figure 1 , 2 As shown, it includes a shell-and-tube heat exchanger 1, an autoclave 2, a soft water tank 3 in a boiler room, and a soft water collection tank 4.

[0013] The above-mentioned shell and tube heat exchanger 1 mainly includes a shell 11, a head 12, a tube sheet 13 and a tube bundle 14. The two ends of the shell 11 are provided with a cover 12, and the tube sheet 13 is arranged between the head 12 and the shell 11, and the tube bundle 14 both ends are supported on the tube sheet 13. Wherein, the shell 11, the tube sheet 13 and the tube bundle 14 are all made of stainless steel, and the head 12 is made of carbon steel.

[0014] The tube bundle 14 is composed of several parallel heat exchange tubes. In this embodiment, the heat exchange tubes are corrugated tubes.

[0015] The shell 11 of the shell-and-tube heat exchanger is provided with a shell-side inlet c and an exhaust port e at the top, a shell-side outlet d at the bottom, a tube-side inlet a at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com