Device and method for measuring and calibrating sound intensity

A technology for calibrating devices and sound intensity, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of increased calibration inaccuracy, high processing and installation requirements, and low accuracy of results, etc., to achieve Convenient instant detection, stable calibration signal, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

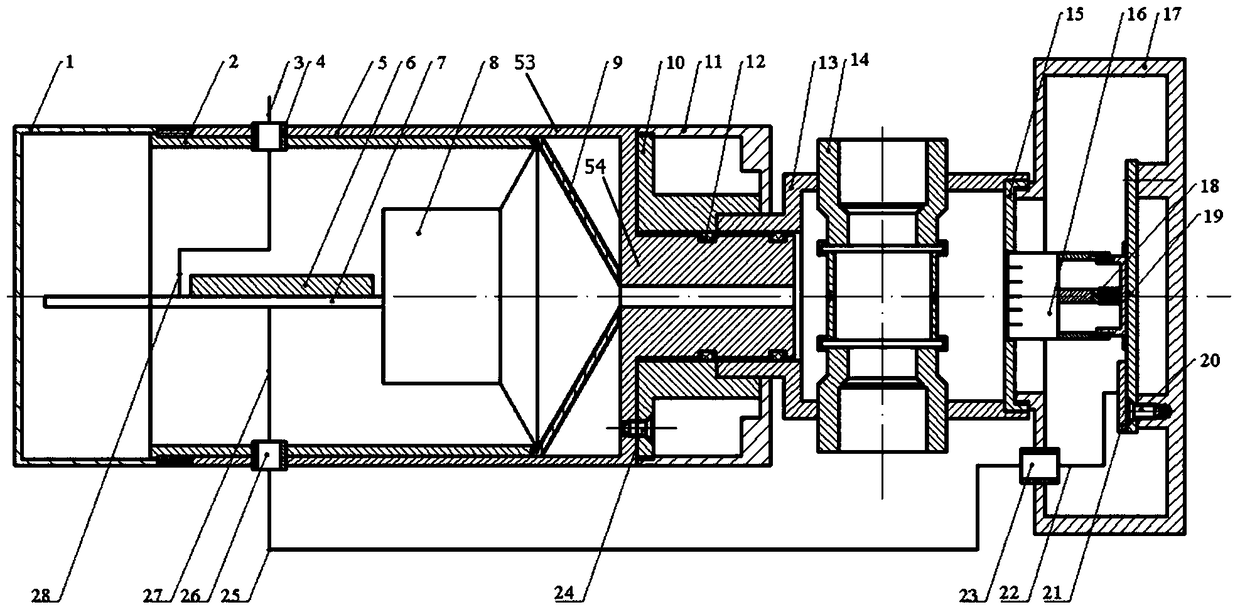

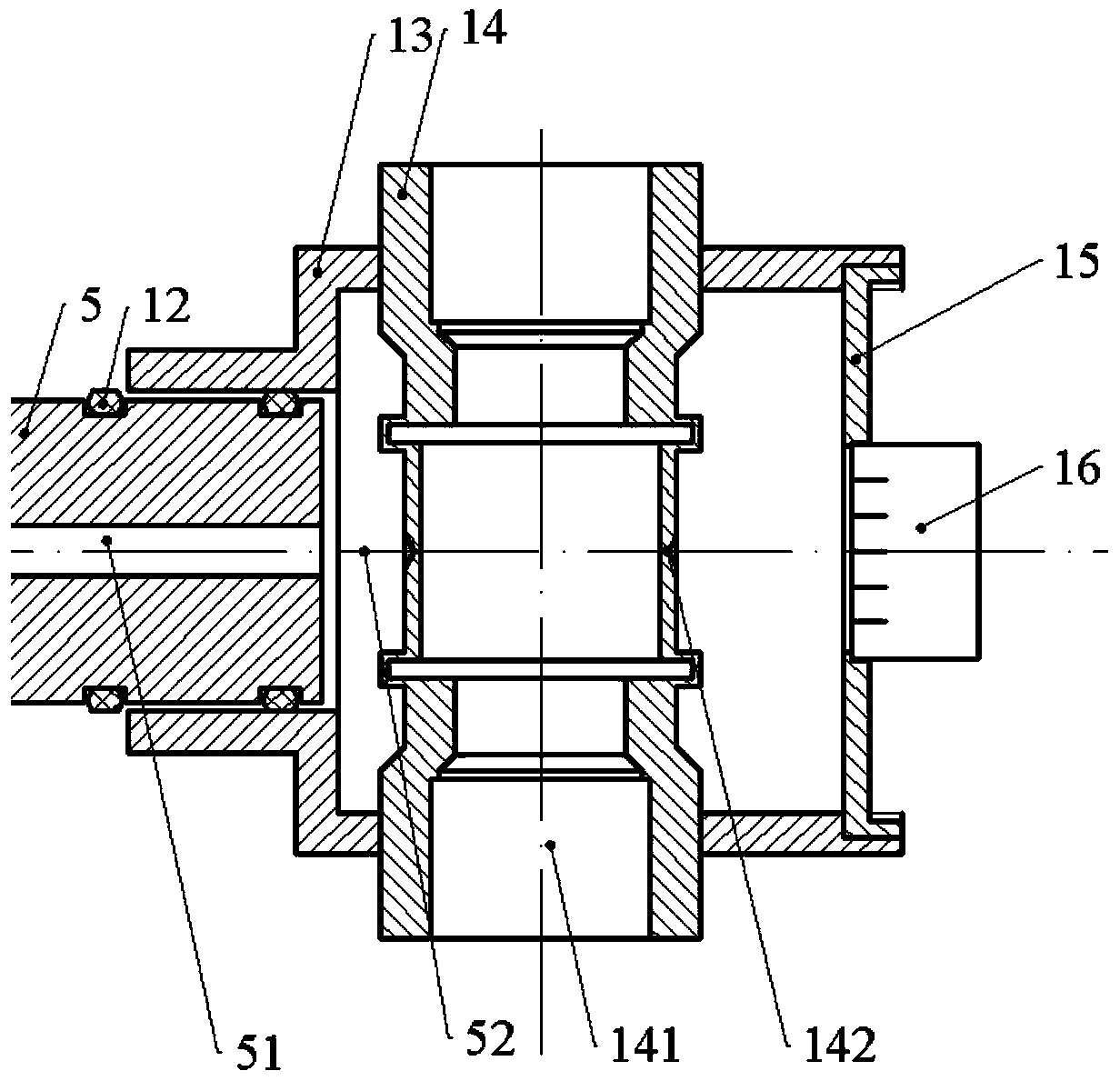

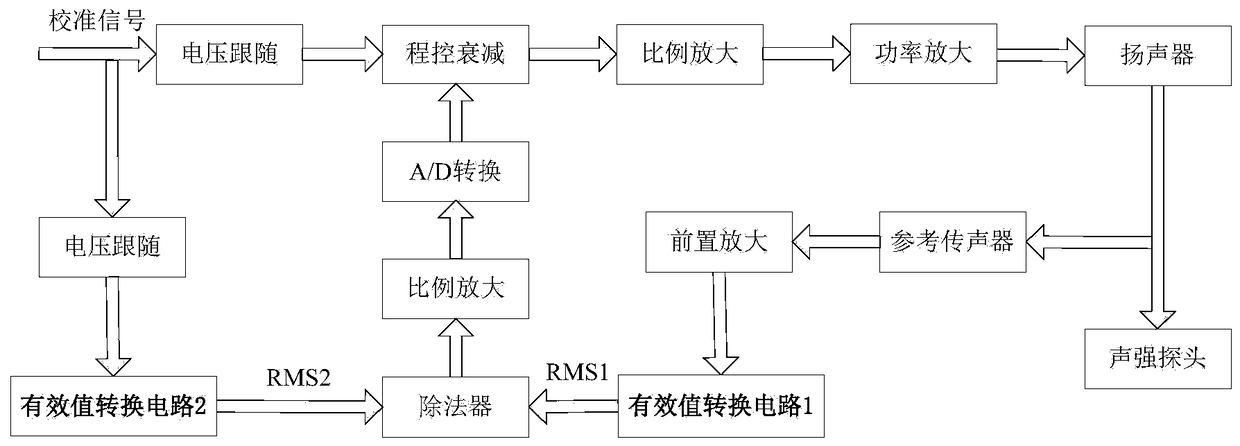

[0027] refer to figure 1 As shown, it is a schematic structural diagram of a sound intensity measurement and calibration device according to an embodiment of the present invention. The sound intensity measuring and calibrating device shown includes: a housing upper cover 1 , a housing 5 , a sleeve 2 , a circuit board 7 , a speaker 8 , a coupling cavity 13 , a coupling element 14 , a coupling cavity bottom cover 15 , and a reference microphone 16 . The shell 5 is divided into an upper end 53 and a lower end 54, and the inner diameter of the lower end 54 is smaller than the inner diameter of the upper end 53, and a sound transmission channel 51 is formed inside the lower end 54; The outer surface is closely matched, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com