Light spring cable and production method thereof

A spring cable, light technology, applied in power cable, insulated cable, cable/conductor manufacturing, etc., can solve the problem that spring cable does not have requirements, and achieve the effect of improving anti-electromagnetic interference performance, high tensile strength and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

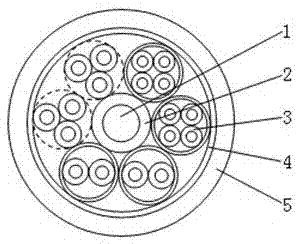

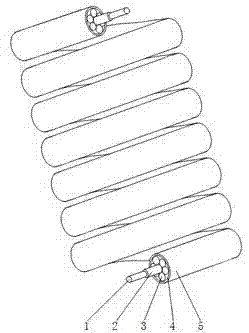

Image

Examples

Embodiment 1

[0025] The outer sheath consists of the following raw materials in parts by weight:

[0026] 900 parts of polyisoprene, 3 parts of boron oxide, 2 parts of N,N'-tetramethyldithiobisthiocarbamide, 0.6 parts of zinc benzenesulfinate, 3.5 parts of p-phenylenediamine, dibasic o-phenylene 5 parts of lead diformate, 22 parts of calcium oxide, 28 parts of carbon black, 1.2 parts of octadecyltrichlorosilane, 4 parts of cesium hydroxide, and 5 parts of dihydrocapsaicin.

Embodiment 2

[0028] The outer sheath consists of the following raw materials in parts by weight:

[0029] 85 parts of polyisoprene, 5 parts of boron oxide, 3 parts of N,N'-tetramethyldithiobisthiocarbamide, 0.6 parts of zinc benzenesulfinate, 2 parts of p-phenylenediamine, dibasic o-phenylene 4 parts of lead diformate, 22 parts of calcium oxide, 30 parts of carbon black, 1.2 parts of octadecyltrichlorosilane, 2 parts of cesium hydroxide, and 4 parts of dihydrocapsaicin.

Embodiment 3

[0031] The outer sheath consists of the following raw materials in parts by weight:

[0032] 92 parts of polyisoprene, 2 parts of boron oxide, 1 part of N,N'-tetramethyldithiobisthiocarbamide, 0.7 parts of zinc benzenesulfinate, 4 parts of p-phenylenediamine, dibasic o-phenylene 5 parts of lead diformate, 18 parts of calcium oxide, 24 parts of carbon black, 0.9 parts of octadecyltrichlorosilane, 5 parts of cesium hydroxide, and 3 parts of dihydrocapsaicin.

[0033] The protective layer of the present invention is made of soft and wear-resistant materials, so as to avoid the abrasion of the wire core caused by the telescopic movement of the steel spring and protect the safety of the wire core. The shielding layer is set as a single or double braid. While improving the anti-electromagnetic interference performance of the product, it does not affect the elastic function, and the vertical stretching tension is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com