Forming method of tungsten electrode

A technology of tungsten electrodes and tungsten layers, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems that the performance of tungsten electrodes cannot meet the development requirements of semiconductor devices, and achieve the effect of improving performance and increasing the formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

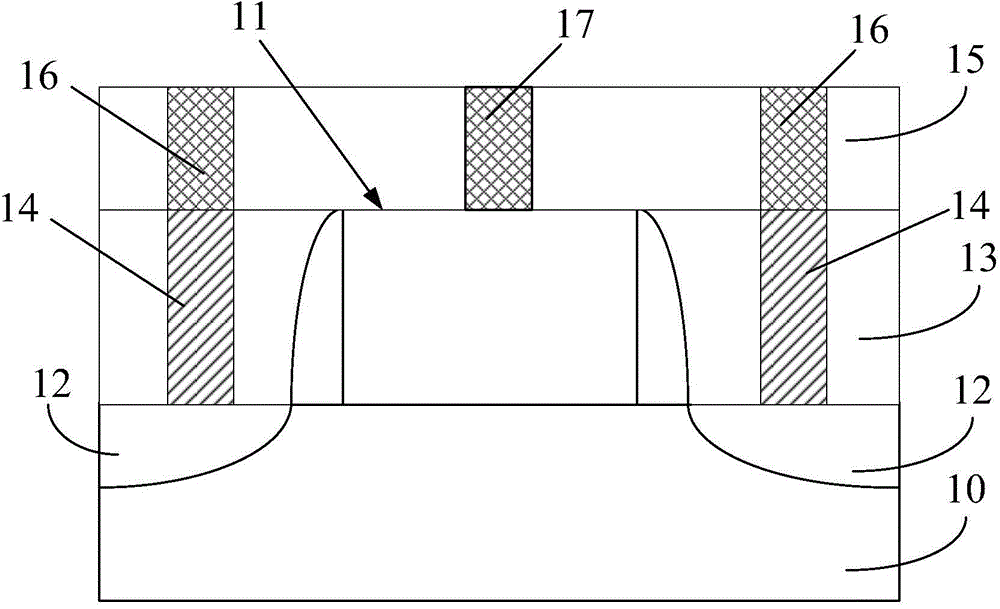

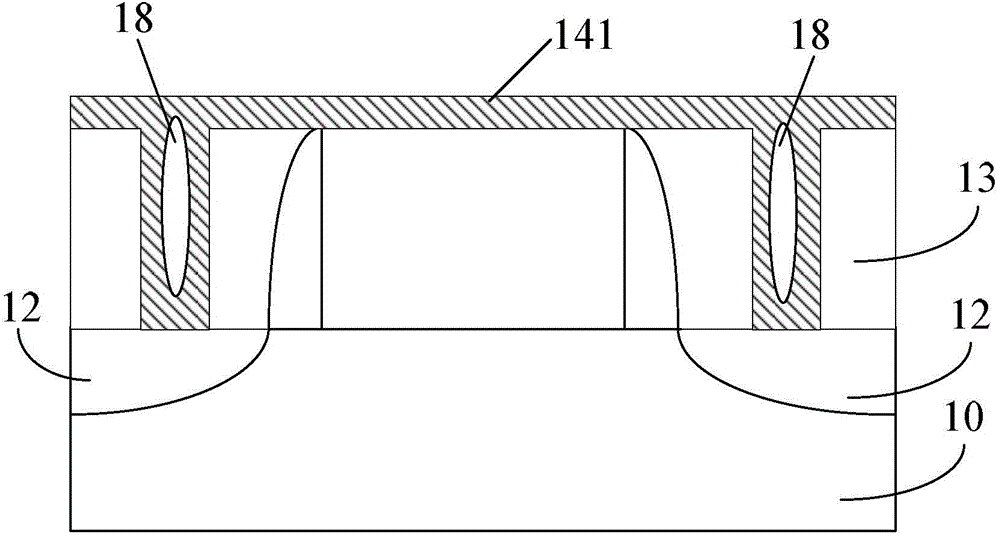

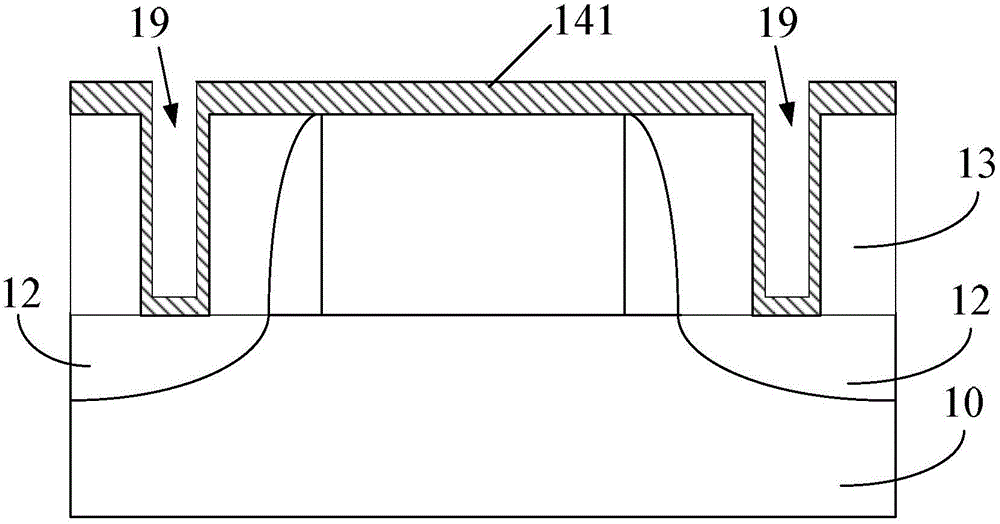

[0046] As mentioned in the background technology, with the development of semiconductor devices, the precision requirements of corresponding semiconductor devices are continuously improved. However, when forming a semiconductor device with a multi-layer structure in the existing process, it is placed in the dielectric layer and used to connect transistors and other layers. Voids will form in the tungsten electrode of the semiconductor element, thereby reducing the performance of the tungsten electrode, thereby affecting the performance of the semiconductor device. Especially with the development of semiconductor devices, the aspect ratio of openings used to form tungsten electrodes is increasing, and the defects of voids in tungsten electrodes are more obvious, which has a greater impact on semiconductor devices with increasing precision requirements.

[0047]Analyzing the reason, with the development of semiconductor technology, the aspect ratio used to form the through hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com