Lithium secondary battery

A lithium secondary battery and non-aqueous electrolyte technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as unmentioned or unmentioned high-temperature cycle characteristics, and achieve excellent overcharge characteristics, excellent charge and discharge Effects of Cyclic Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105]

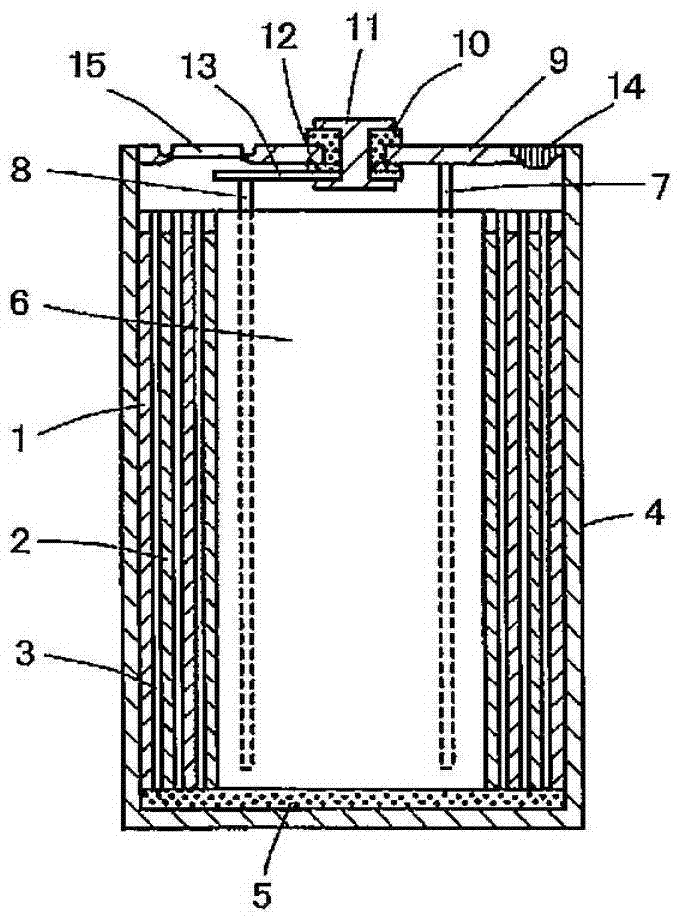

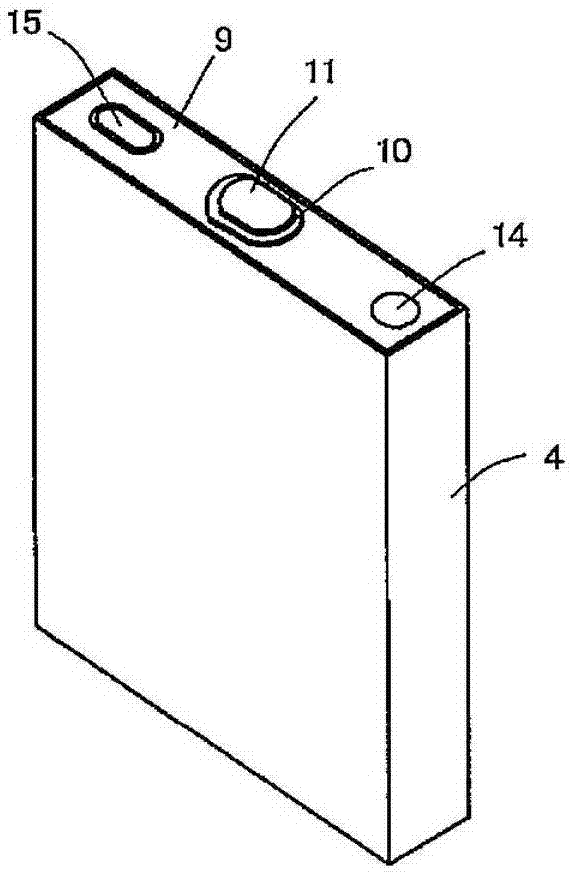

[0106] LiCoO 2 100 parts by mass, 20 parts by mass of NMP solution containing PVDF as a binder at a concentration of 10 mass%, 1 part by mass of artificial graphite as a conductive additive, and 1 part by mass of Ketjen Black were kneaded with a twin-screw mixer, NMP was further added to adjust the viscosity to prepare a paste containing positive electrode mixture.

[0107] The positive electrode mixture-containing paste was coated on both sides of an aluminum foil (positive electrode current collector) with a thickness of 15 μm, and then vacuum-dried at 120° C. for 12 hours to form positive electrode mixture layers on both sides of the aluminum foil. Then, pressure treatment was performed to adjust the thickness and density of the positive electrode mixture layer, and an aluminum lead body was welded to the exposed portion of the aluminum foil to produce a strip-shaped positive electrode with a length of 600 mm and a width of 54 mm. The thickness of each side of t...

Embodiment 2~8

[0121] The amount of the complex obtained by coating the surface of SiO with a carbon material, adiponitrile, LiBF 4 Except having changed the content of each as shown in Table 1, it carried out similarly to Example 1, and produced the lithium secondary battery.

Embodiment 9

[0123]

[0124] The amount of the Si powder when the total of the Si powder and the graphite is 100% by mass when the Si powder as the material S and the graphite having an average particle diameter D50% of 16 μm as a carbon material capable of occluding and releasing lithium ions becomes A mixture of 0.1% by mass: 99.0 parts by mass, SBR as a binder: 1.5 parts by mass, and CMC as a thickener: 1 part by mass was added to water and mixed to prepare a negative electrode mixture-containing paste. A negative electrode was produced in the same manner as in Example 1, except that this negative electrode mixture-containing paste was used.

[0125]

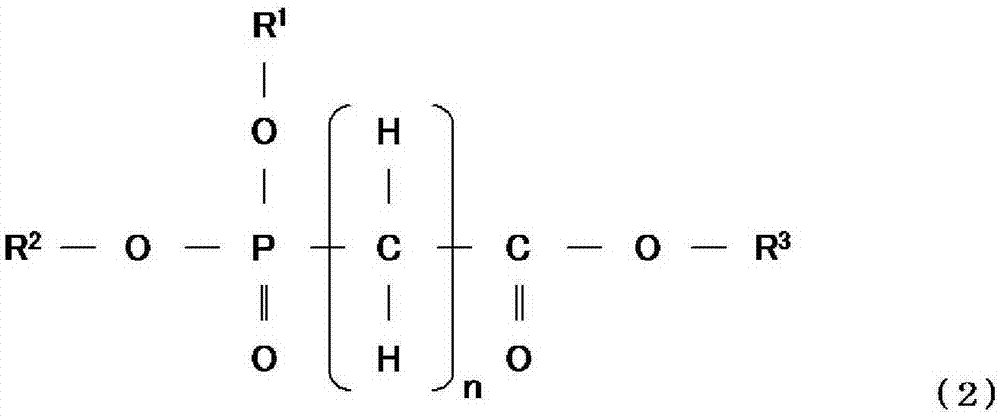

[0126] In a mixed solvent with a volume ratio of ethylene carbonate and diethyl carbonate of 3:7, the LiPF 6 Dissolve at a concentration of 1.1 mol / l, and add the following substances in the following amounts: adiponitrile to 0.1% by mass, lithium borofluoride (LiBF 4 ) was 1.0% by mass, VC was 2% by mass, and FEC was 2% by mass to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com