Reclaimed precoated sand and batching system thereof

A batching system and coated sand technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, casting molds, etc., can solve the problems of not being able to put into production, so as to improve utilization rate, strength and curing degree , The effect of purifying the workplace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to better understand and implement the technical solutions of the present invention, some embodiments of the invention are provided here. These embodiments are for better explaining the technical solutions of the present invention, and do not constitute any formal restrictions on the present invention.

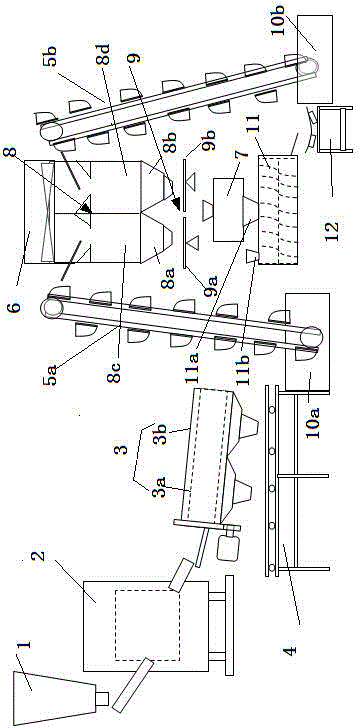

[0011] Refer to the following figure 1 The technical solution of the present invention will be described in detail, wherein: 1: Recycling bin, 2: Iron remover, 3: Screening machine, 3a: Inner sieve, 3b: Outer sieve, 4: Conveyor belt, 5: Bucket elevator , 5a: recycled sand bucket elevator, 5b: original sand bucket elevator, 6: dust removal device, 7: mixer, 8: silo, 8a: discharge port 1, 8b: discharge port 2, 8b: regeneration Sand silo, 8c: Raw sand silo, 9: Weighing scale, 9a: Weighing scale 1, 9b: Weighing scale 2, 10a: Regenerated sand tank, 10b: Raw sand tank, 11: Drum heating machine, 11a : additive inlet, 11b: mixture inlet, 12: finished product conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com