A Multi-parameter Synchronous Visual Inspection and Tracking Method for Trapezoid Welds with Variable Gap

A visual inspection and multi-parameter technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that the inflection point of the trapezoidal weld cannot meet the welding requirements, and cannot obtain the size of the weld gap and the height direction Z Direction deviation and other problems can be solved to save image processing time, improve real-time performance and adaptability, and reduce requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

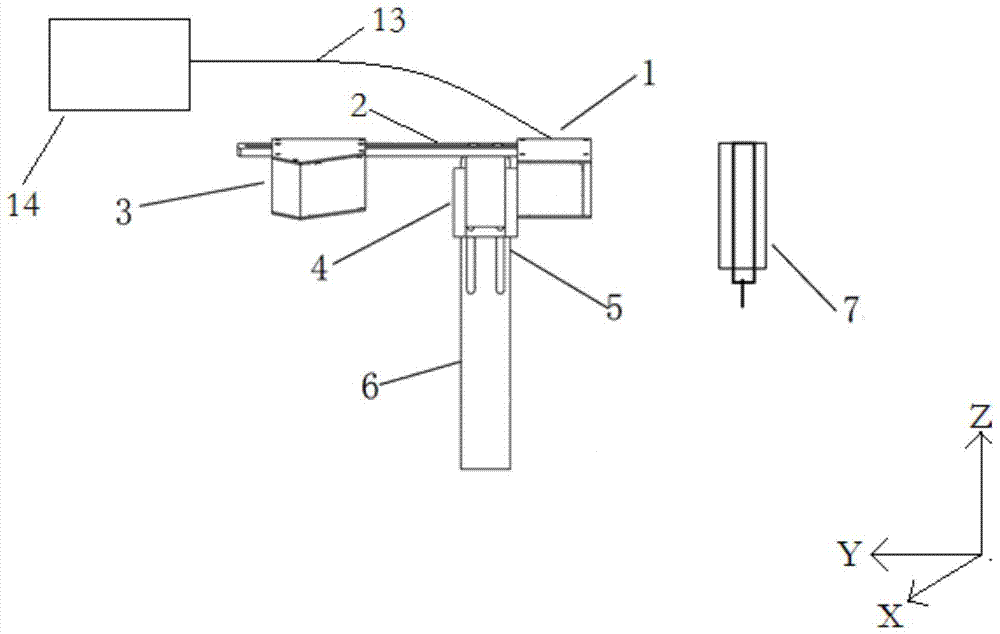

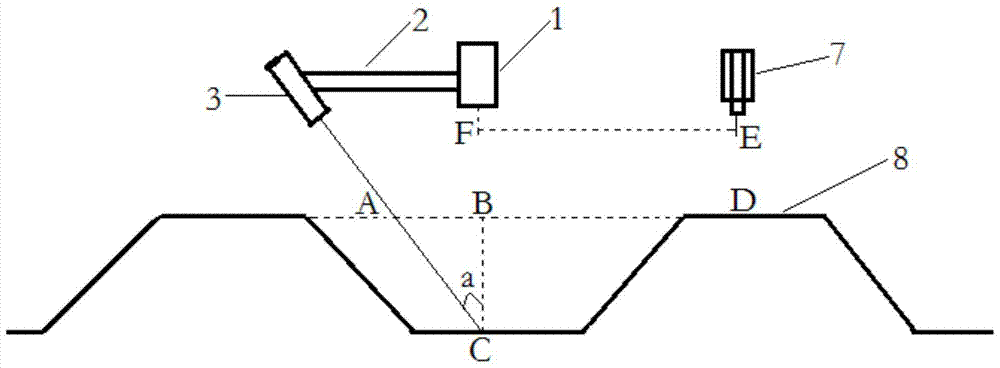

[0077] The specific steps of the variable-gap trapezoidal weld multi-parameter synchronous visual detection and tracking method in this embodiment are:

[0078] The first step, image processing and feature extraction

[0079] 1-1 Image Acquisition: Acquire the image of the weld area including laser stripes through the smart camera sensor;

[0080] 1-2 Image threshold adaptive segmentation: On the basis of step 1-1, select the pixel value with the same number of pixels with the largest number of pixel values as the threshold value on the basis of step 1-1, and select the pixel value greater than the threshold value in every five columns , which is determined as an effective point of the laser stripe, and the effective point is segmented from the image;

[0081] 1-3 Laser stripe center line extraction: extract the effective points of the laser stripes determined in step 1-2 column by column, extract the effective points of each column of laser stripes, and store the intermedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com