Laser welding tool for thin wall complex surface cabin body and molding method

A complex curved surface, laser welding technology, applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of long processing cycle, low material utilization rate, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

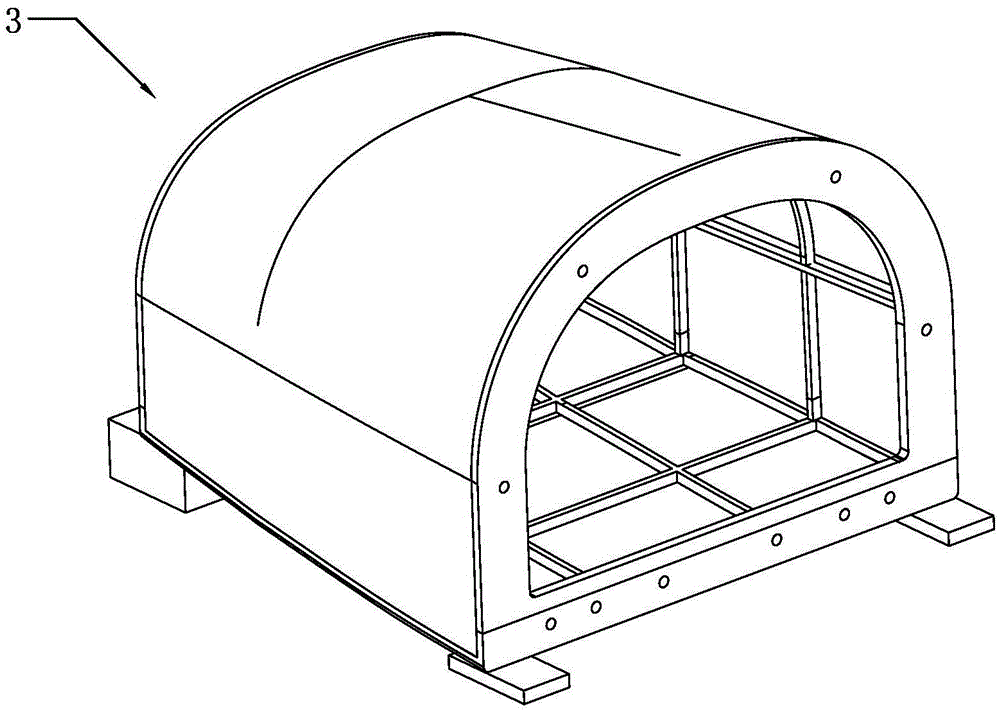

[0060] The thin-walled complex curved cabin body 3 in this specific embodiment is made of titanium alloy material, but not limited thereto, as long as it is suitable for laser welding.

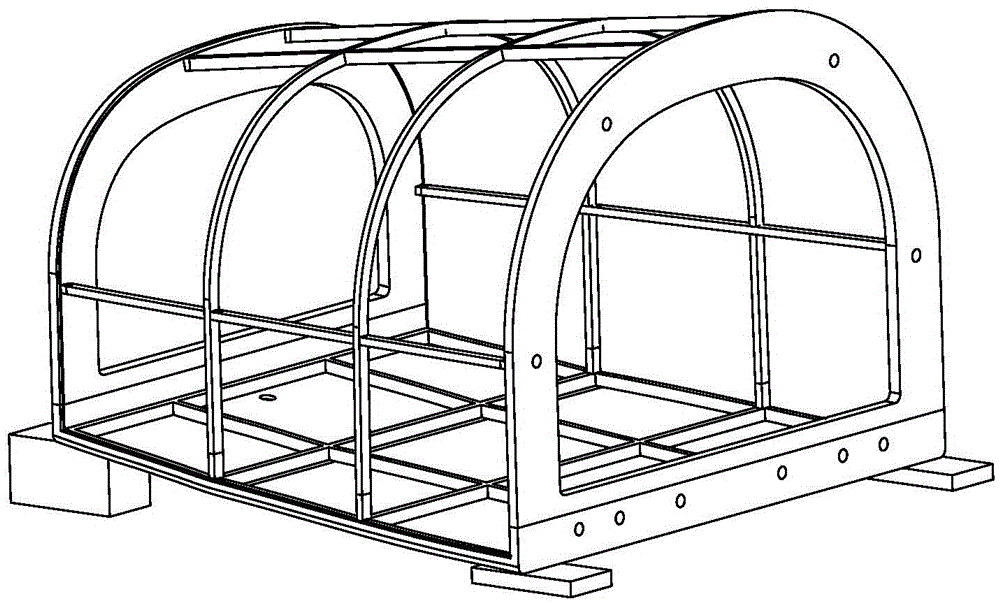

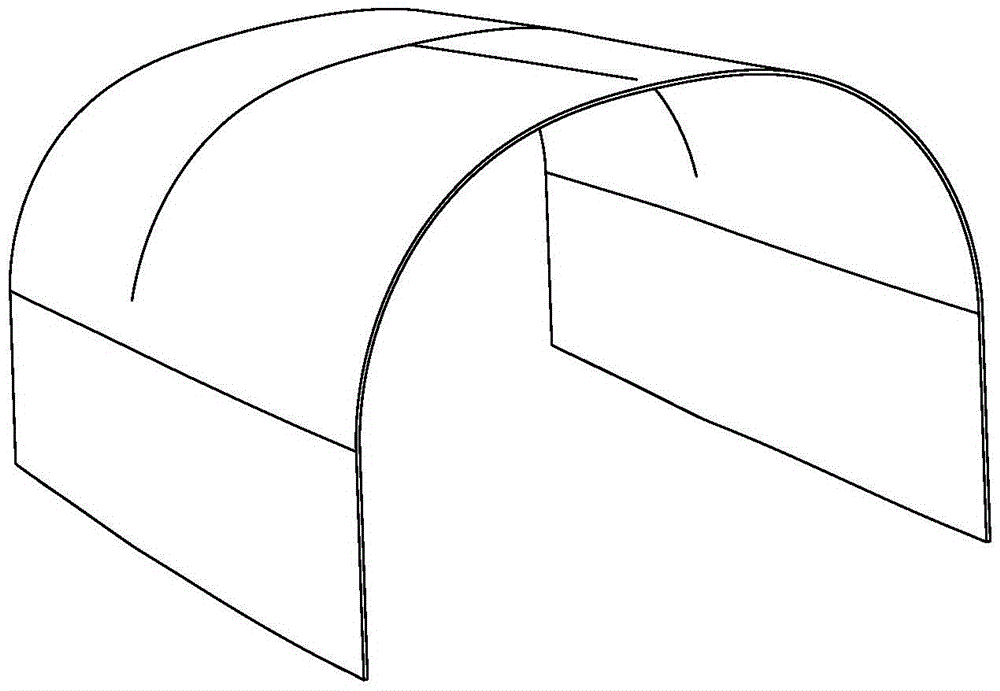

[0061] The laser welding tooling of the thin-wall complex curved surface cabin body 3 in the present invention includes a support frame body, a strap assembly, a front cover 1 and a rear cover plate 2, and the support frame body is used to fix the thin-wall complex curved surface cabin body 3, including The belt assembly includes a strap 4 and a connecting piece, each of the two ends of the strap 4 is fixed with a connecting piece, and the strap 4 is provided with a positioning through hole 5, and the connecting piece is used to connect the strap 4 and the supporting frame body. The front and rear cover plates 1 and 2 are all provided with a ring sealing ring 6, and the front and rear cover plates 1 and 2 are respectively used to be fixed on the front and rear panels of the thin-walled complex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com