Optimization of wastewater fluorine-removal method and process through sludge refluxing effect

A technology for sludge return and waste water, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc. problems, to achieve the effect of reducing the dosage, improving the utilization rate of lime, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

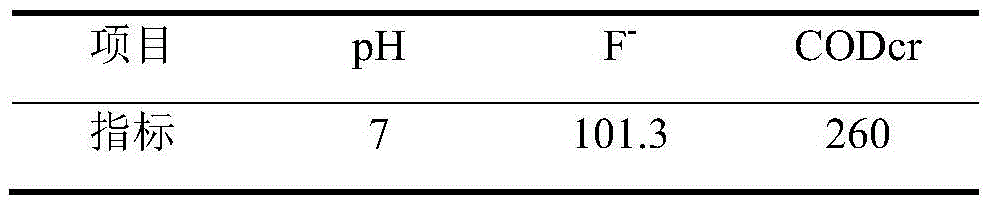

[0025] The quality of wastewater before defluoridation treatment is as follows (mg / L):

[0026]

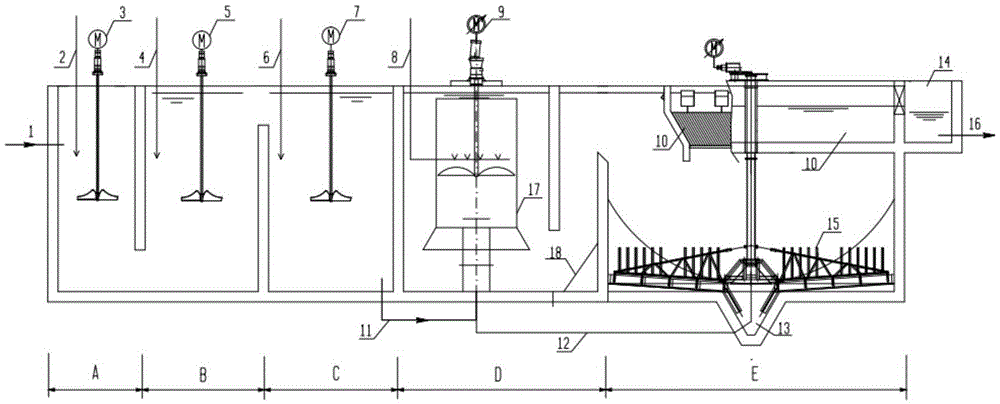

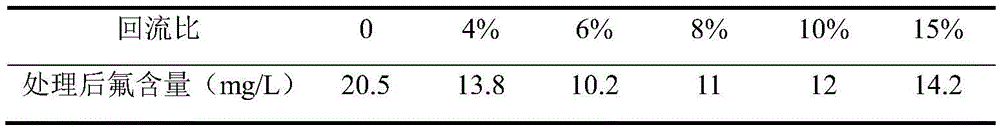

[0027] Take 500mL of fluorine-containing waste water from the coal chemical industry and first enter the lime dosing area A through the water inlet pipe 1 of the small test device, and add 4mL of 10% lime solution to the lime dosing area A, stir with a mechanical stirrer for 15 minutes, and measure Its pH value is about 11; after the wastewater enters the acid addition area B, add sulfuric acid solution to adjust the pH to 8-9, and the dosage of sulfuric acid is 1.5mL; after the wastewater enters the coagulation area C, the dosage concentration is 10 % polyaluminum chloride coagulant 1.5mL, fully stirred for 2min, after the waste water enters the flocculation area D through the bottom pipe 11, add 0.5mL of the flocculant polyacrylamide solution with a concentration of 10%, and after stirring slowly for 15min, the sewage passes through The push flow wall 18 enters the simulated ...

Embodiment 2

[0033] Divide into 4 groups of experiments. Ensure that other conditions remain unchanged in Example 1, the sludge return rate is 6%, and the amount of lime added in the lime dosing area A is 2mL, 4mL, 6mL, 8mL respectively, that is, the dosing concentration is 400mg / L respectively , 800mg / L, 1200mg / L, 1600mg / L. After processing finished, take out the water that water pipe 16 discharges and measure its fluorine content. After defluoridation treatment, the fluoride ion concentration in the treated water is shown in the table below:

[0034]

[0035] It can be seen from the treatment results that when the lime concentration is 400mg / L to 1600mg / L, the fluoride ion content in the treated wastewater is below 15mg / L, and when the lime concentration is 800mg / L, the fluoride ion content in the treated wastewater lowest concentration. After that, with the increase of lime concentration, the removal efficiency of fluorine changed little.

[0036] In addition, it has been verifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com