Treatment method for excess activated sludge in AOX pollution

A treatment method and residual activity technology, applied in the fields of environmental engineering and pollution treatment engineering, can solve the problems of large dosage and troublesome subsequent treatment of sludge, and achieve the effect of reducing treatment cost, realizing harmlessness and reducing water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The AOX content in the remaining activated sludge of a pharmaceutical company is as high as 5347mg / kg (dry sludge), the moisture content of the raw sludge is 95.7%, and the initial pH is 7.8.

[0050] The treatment method of above-mentioned excess activated sludge is as follows:

[0051] (1) Add the modified fly ash of the load iron manganese element of 100mg / g. dry SS in the remaining activated sludge, stir with 180r / min, after mixing evenly, obtain mixed solution; Wherein, by mass fraction, Nano Fe in modified fly ash 3 o 4 The loading is 10%, Mn 2+ The loading amount is 2%.

[0052] After the fly ash is modified, the specific surface area is changed from the original 8.2m 2 / g, increased to 21.5m 2 / g.

[0053] (2) Add 40 mg / g. dry SS H to the mixture 2 o 2 , stirred at 180r / min, and after 2 hours of oxidation reaction, a reaction solution was obtained.

[0054] After 30 minutes of reaction, the pH value of the reaction solution dropped to 3.4; after 2 hours...

Embodiment 2

[0061] In the present embodiment, in terms of mass fraction, the nanometer Fe in the modified fly ash 3 o 4 The loading is 10%, Mn 2+ The loading amount is 5%.

[0062] After the fly ash is modified, the specific surface area is changed from the original 8.2m 2 / g, increased to 22.3m 2 / g.

[0063] Other than that, the rest of the content is the same as in Example 1.

[0064] Treatment results: After treatment, the capillary water absorption time of the sludge decreased from 265.6s to 18.9s, the moisture content of the sludge filter cake decreased to 49.1%, and the sludge AOX removal rate was 76.8%.

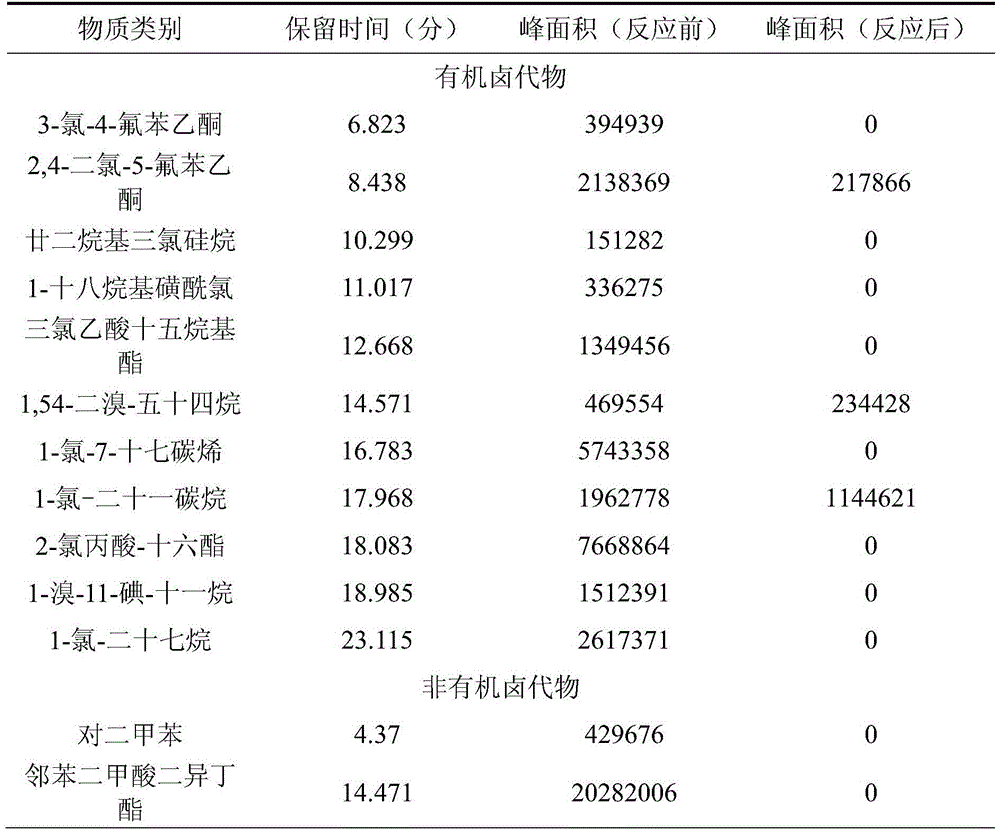

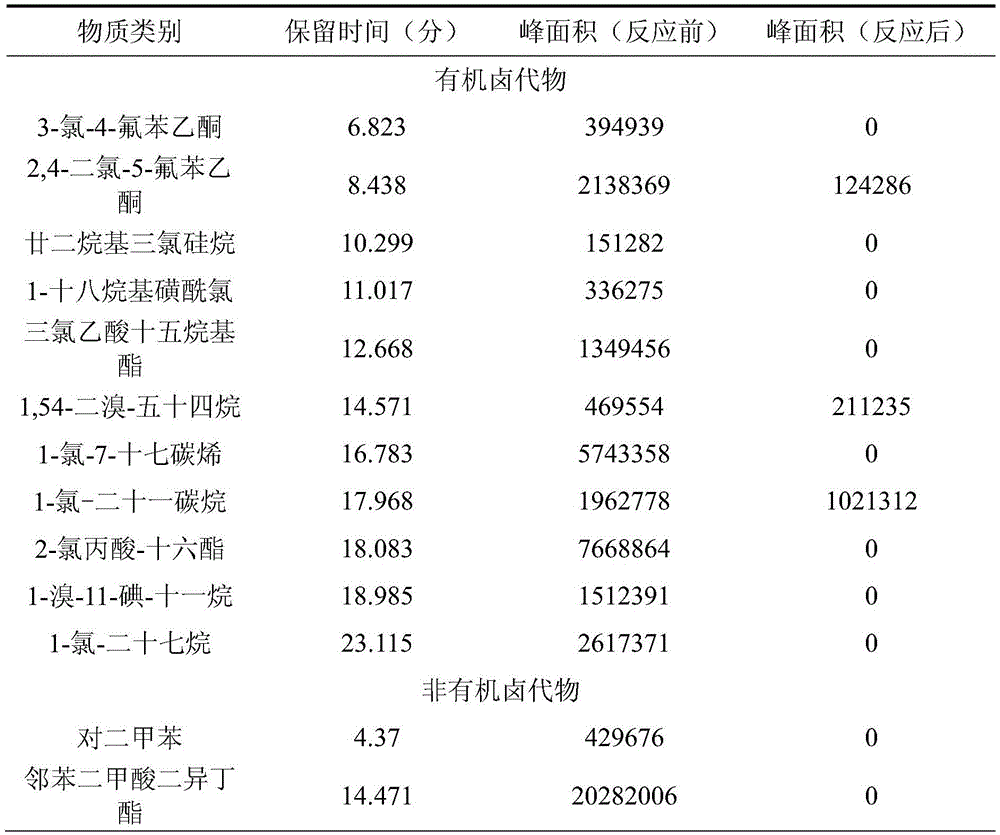

[0065] The changes of main pollutants in sludge before and after oxidation treatment are shown in Table 2.

[0066] Table 2 GC-MS detects the changes in compound types and peak areas before and after the treatment of the remaining activated sludge in Example 2

[0067]

Embodiment 3

[0069] In the present embodiment, in terms of mass fraction, the nanometer Fe in the modified fly ash 3 o 4 The loading is 5%, Mn 2+ The loading amount is 1%.

[0070] After the fly ash is modified, the specific surface area is changed from the original 8.2m 2 / g, increased to 14.5m 2 / g.

[0071] Other than that, the rest of the content is the same as in Example 1.

[0072] Treatment results: After treatment, the capillary water absorption time of the sludge decreased from 265.6s to 80.2s, the moisture content of the sludge filter cake decreased to 60.2%, and the sludge AOX removal rate was 66.2%.

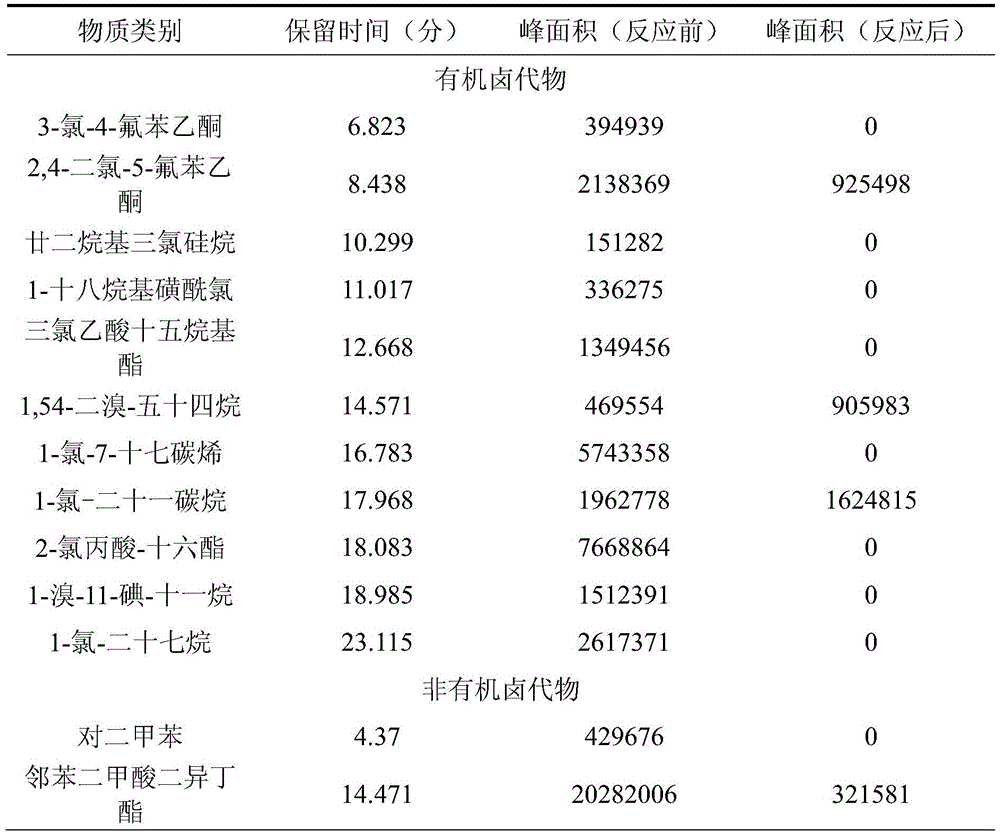

[0073] The changes of the main pollutants in the sludge before and after treatment are shown in Table 3.

[0074] Table 3 GC-MS detects the change of compound type and peak area before and after the remaining activated sludge treatment in Example 3

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com