Premixed polyether polyol, polyisocyanurate foam, as well as raw material composition and preparation method of polyisocyanurate foam

A technology of polyisocyanurate and combined polyether, which is applied in the field of combined polyether, polyisocyanurate foam and its raw material composition and preparation, can solve the problem of polyisocyanurate foam flame retardancy and Poor environmental protection and other problems, to achieve excellent flame retardant performance, the effect of small foam smoke production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 4

[0060] Embodiment 1~Example 4, comparative example 1 and comparative example 4

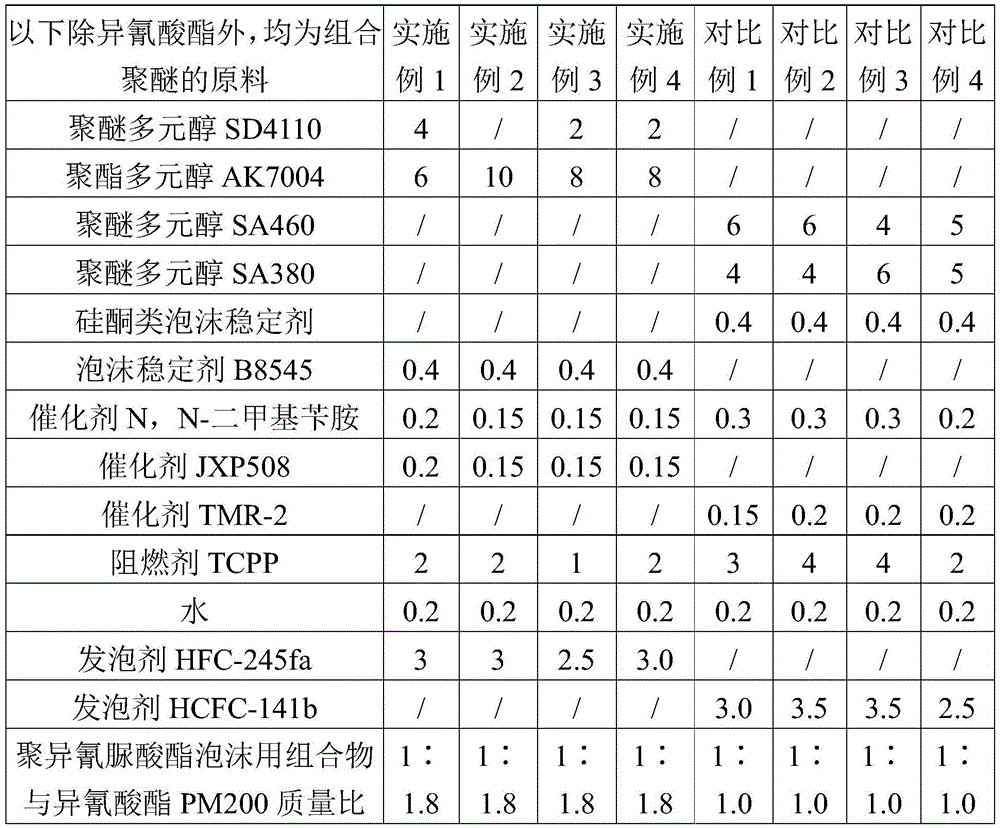

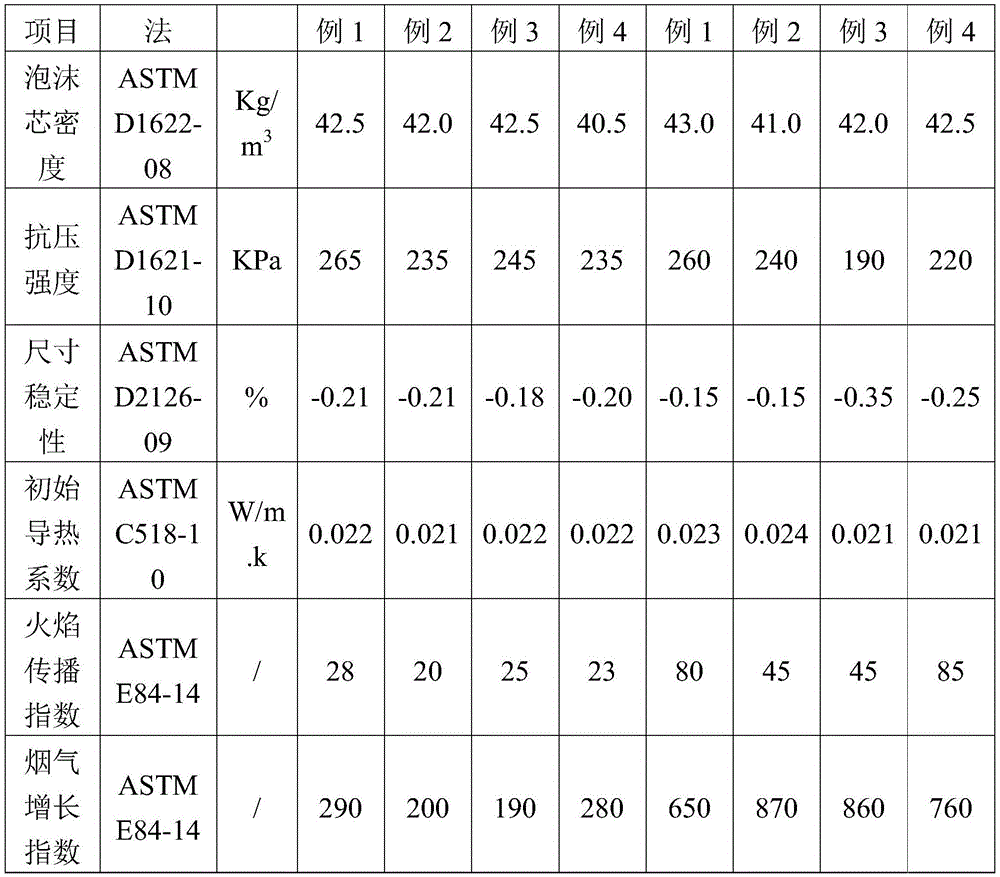

[0061] See Table 1 for the raw material formulations of Examples 1 to 4, Comparative Example 1 and Comparative Example 4 of the present invention, and see Table 2 for the effect data. Specific steps are as follows:

[0062] According to the formula in Table 1, add all ingredients except isocyanate into a stainless steel mixing tank, stir at room temperature at a speed of 10r / min for 1 hour, and discharge to obtain a combined polyether for polyisocyanurate foam.

[0063] According to the formula in Table 1, the prepared combined polyether and isocyanate PM200 are subjected to foaming reaction at 20°C according to the mass ratio, and injected into the mold to obtain a core density of about 40Kg / m 3 The rigid polyurethane foam insulation material, the physical properties of each embodiment and comparative example gained rigid polyurethane foam are shown in Table 2. " / " in Table 1 means no addition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com