Environment-friendly copper technology clay sculpture material and preparation method thereof

A copper art clay plastic material, an environmentally friendly technology, applied in the field of clay sculpture, can solve the problems of users' physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

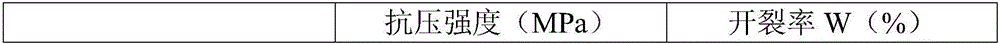

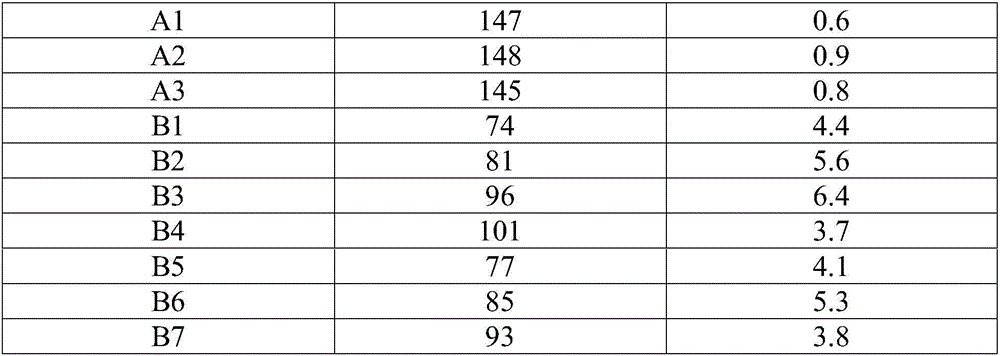

Examples

preparation example Construction

[0013] The invention provides a preparation method of an environmentally friendly copper art clay plastic material, including:

[0014] 1) Soak calamus leaves and cotton in nitric acid solution, then filter and wash to obtain filter cake;

[0015] 2) Mixing loess, black loam, attapulgite, konjac flour, polyvinyl alcohol, gelatin, sodium lauryl ether sulfate, 1-ethynyl-1-cyclohexanol and water and aging treatment to prepare Aging product

[0016] 3) The aging product, filter cake, maltitol and sodium tripolyphosphate are mixed, steamed, and then cooled to prepare an environmentally friendly copper art clay plastic material.

[0017] In step 1) of the present invention, the amount of each material can be selected in a wide range, but in order to further improve the non-cracking properties and mechanical strength of the prepared copper art clay plastic material, preferably, in step 1), relative For 1 part by weight of calamus leaves, the amount of cotton used is 1.6-3 parts by weight, a...

Embodiment 1

[0028] 1) Mix calamus leaves, cotton and nitric acid solution (pH 5) at a weight ratio of 1:2:25 at 25°C and soak for 13h, then filter and wash to obtain filter cake;

[0029] 2) Combine loess (particle size 25μm), black loess (particle size 25μm), attapulgite (particle size 25μm), konjac powder, polyvinyl alcohol, gelatin, sodium lauryl ether sodium, 1- Ethynyl-1-cyclohexanol and water were mixed in a weight ratio of 100:23:13:3.7:37:3:2.5:0.7:130, and then aged at 40°C for 2.5 days to obtain an aged product;

[0030] 3) Mix the aged product, filter cake, maltitol and sodium tripolyphosphate in a weight ratio of 100:30:13:6.5, and cook at 180°C for 5.5h, and then cool at 25°C to prepare Environmental protection copper art clay plastic material A1.

Embodiment 2

[0032] 1) Mix calamus leaves, cotton and nitric acid solution (pH 4.5) at a weight ratio of 1:1.6:20 at 15°C and soak for 10h, then filter and wash to obtain a filter cake;

[0033] 2) Combine loess (particle size of 20μm), black loess (particle size of 20μm), attapulgite (particle size of 20μm), konjac powder, polyvinyl alcohol, gelatin, sodium lauryl ether sulfate, 1- Ethynyl-1-cyclohexanol and water were mixed in a weight ratio of 100:20:9:3.5:34:2:2:0.5:120, and then aged at 35°C for 2 days to obtain an aged product;

[0034] 3) Mix the aged product, filter cake, maltitol and sodium tripolyphosphate in a weight ratio of 100:26:10:4.5, and cook at 150°C for 5 hours, and then cool at 15°C to prepare an environmentally friendly Copper art clay sculpture material A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com