Electrophoretic coating line pretreatment and electrophoresis apparatus

An electrophoretic coating and electrophoretic device technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve problems such as inability to completely remove oil stains on the surface of workpieces, good electrophoretic paint coatings, and inability to obtain corrosion resistance, etc. Appearance quality, good corrosion resistance, and the effect of preventing re-dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

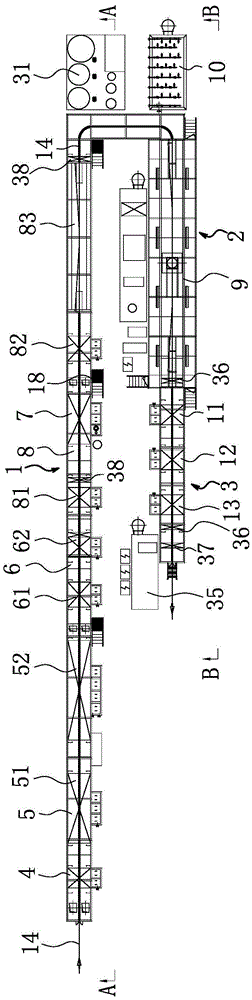

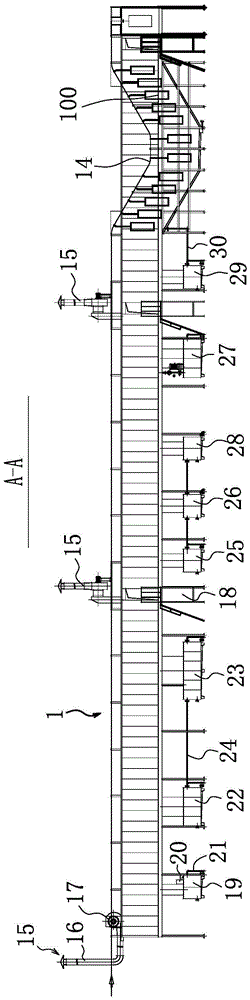

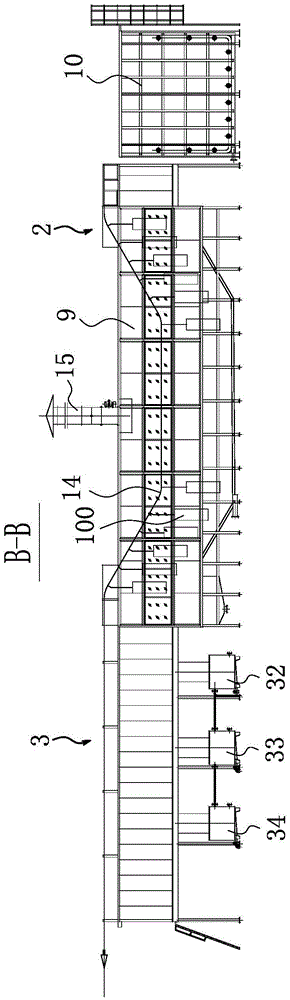

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] like Figure 1-3 As shown, a pretreatment and electrophoresis device of an electrophoretic coating line includes a water washing and degreasing system 1, an electrophoresis system 2 and an ultrafiltration cleaning system 3 connected to each other. The water washing and degreasing system 1 includes a hot water tank 4 connected in sequence, a degreasing Groove 5, washing tank 6, vitrification tank 7 and pure water tank 8, described electrophoresis system 2 comprises electrophoresis tank 9 and electrophoresis transfer tank 10, and described ultrafiltration cleaning system 3 comprises primary ultrafiltration cleaning tank 11 connected in sequence , secondary ultrafiltration cleaning tank 12 and three ultrafiltration cleaning tanks 13, the above described water washing and degreasing system 1, electrophoresis system 2 and ultrafiltr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com