Mark with focusing and slant correction function and aligning method

A tilt correction and marking technology, applied in optical mechanical equipment, photo-engraving process of pattern surface, optics, etc., can solve the problem of affecting measurement reproducibility, error, insufficient to achieve high-precision focusing and leveling, and achieve improved Measurement reproducibility, high-precision focusing and leveling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

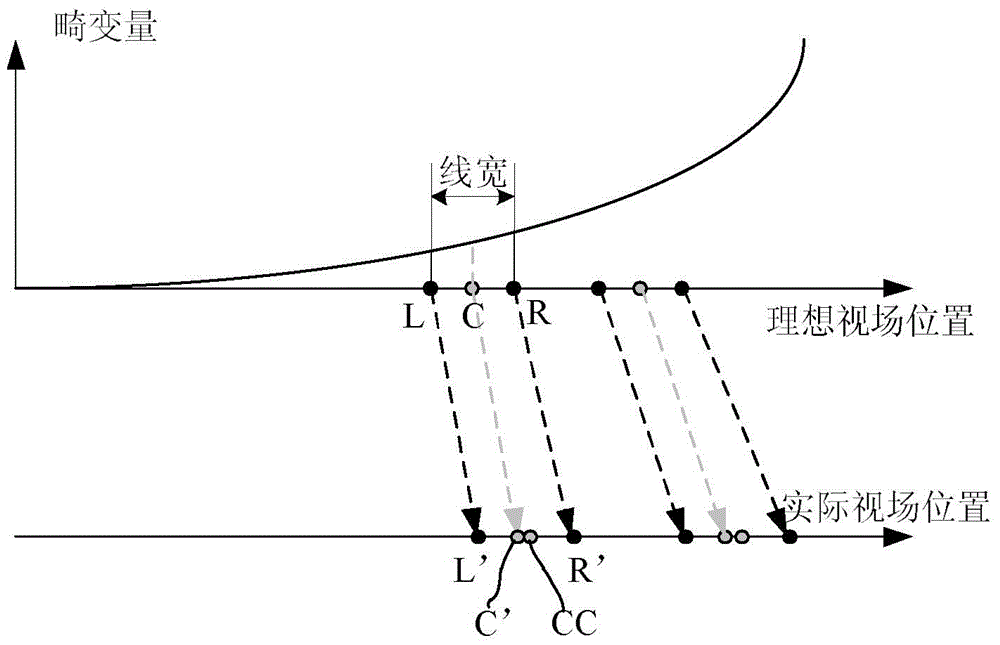

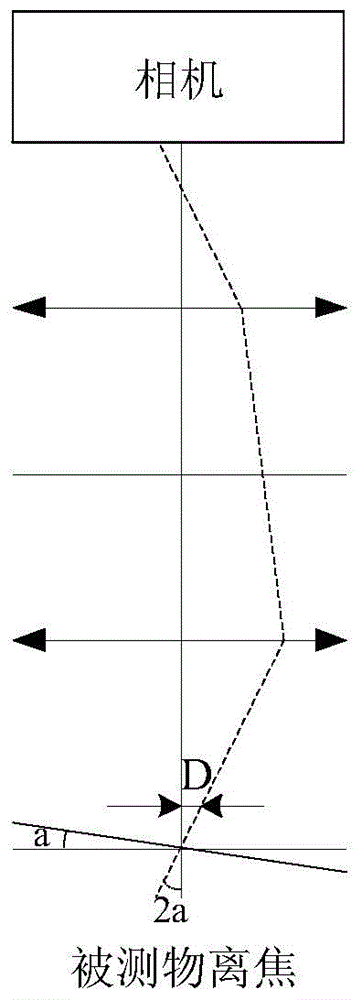

[0053] like Figure 4As shown, Embodiment 1 of the present invention provides a mark with a focus adjustment and tilt correction design, the mark includes an alignment mark 20 and at least one pair of focus adjustment marks, and the focus adjustment mark is a square type focus mark or a grating type Focusing marks, the grating-type focusing marks are horizontal grating-type focusing marks or vertical grating-type focusing marks, and the focusing marks include a pair of square-type focusing marks, a pair of horizontal grating-type Focus marks and a pair of vertical grating-type focus marks, the focus marks include square-type focus marks 10, square-type focus marks 30, horizontal grating-type focus marks 11, horizontal grating-type focus marks 31. The vertical grating-type focusing mark 12 and the vertical grating-type focusing mark 32 . Among them, the square-shaped focusing mark 10 and the square-shaped focusing mark 30 are a pair of square-shaped focusing marks, and the hor...

Embodiment 2

[0100] Different from Embodiment 1, in Embodiment 2, the center of the alignment mark is not necessarily located at the midpoint of any pair of focusing marks, but only the distance to the two focusing marks is known. The best focus plane position of the alignment mark is obtained by using the known distance from the alignment mark to the two focusing marks. Compared with the first embodiment, the second embodiment provides a mark with less restrictive conditions, which meets the diverse needs of users.

[0101] In Embodiment 2, except for the above content, the marking and alignment methods are consistent with Embodiment 1, so details will not be repeated here.

Embodiment 3

[0103] Different from the first embodiment, in the third embodiment, the alignment mark is a horizontal line mark or a vertical line mark, which is used to measure the position in one direction. Compared with Embodiment 1, Embodiment 3 provides a marker for measuring a position in one direction, which meets the diverse needs of users.

[0104] In the third embodiment, except for the above content, the marking and alignment methods are the same as those in the first embodiment, so no more details are given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com