Composite graphene optical fiber cable and preparation method thereof

A fiber optic cable, graphene technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

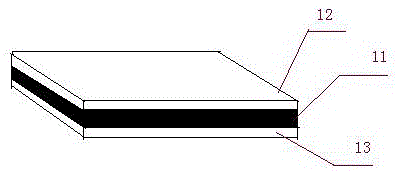

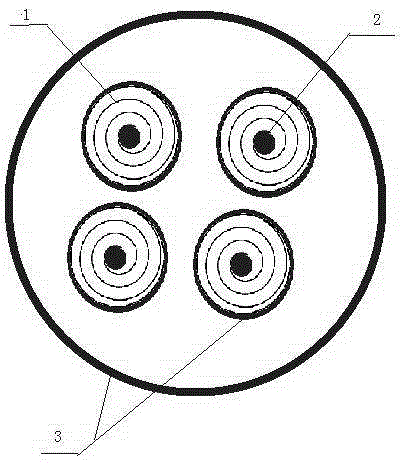

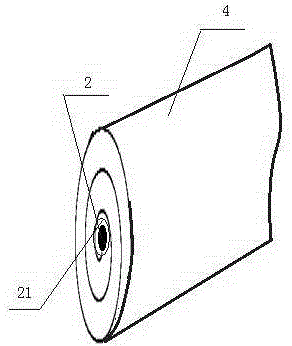

[0038] A composite graphene optical fiber cable, comprising: a silica optical fiber 2, a silica optical fiber cladding 21, a copper foil graphene film layer 1, and a protective insulating layer 3. It is characterized in that a layer of graphene film 12 is deposited and grown on the copper foil 11 by CVD method to form a copper foil graphene film layer 1, the copper foil 11 side of the copper foil graphene film layer 1 is coated with an adhesive layer 13, and the quartz optical fiber The outer layer of the fiber core of 2 is wrapped with a layer of silica fiber cladding 21, and the copper foil 11 of the grown graphene film 12 is wound on the outer layer of the silica fiber 2 to form a graphene fiber conductor 4, and the graphene fiber conductor 4 A layer of insulating protective layer 3 is coated on the outside to form a graphene optical fiber cable. Because graphene has high conductivity, its electron mobility is more than 100 times that of copper. The graphene conductive laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com