Preparation method of single-layer closely-arranged nano-microsphere arrays

A nano-microsphere and close-packed technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high price and easy damage to the template layer close-packed structure by motors, and achieve low cost, simple structure, and high liquid level. small perturbation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Silicon wafer cleaning: put the 10mm×15mm Si(100) substrate in deionized water for 10 minutes, ultrasonic cleaning in toluene for 10 minutes, ultrasonic cleaning in deionized water for 5 minutes, ultrasonic cleaning in acetone for 10 minutes, and then in deionized water for 10 minutes. Ultrasonic cleaning in water for 5 min, ultrasonic cleaning in ethanol for 10 min, and ultrasonic cleaning in deionized water for 5 min; prepare a solution of sulfuric acid (97%) and hydrogen peroxide (30%) with a volume ratio of 3:1, place the silicon chip in the solution and heat it at 80 Ultrasonic at ℃ for 2h, then take out and ultrasonically clean in deionized water for 3 times, each time for 5min; The wafer was placed in the solution and ultrasonicated at 80°C for 2 hours, then ultrasonically cleaned in deionized water for 10 minutes; then the silicon wafer was soaked in SDS (tetrahydrofuran, 10% concentration) solution for 12 hours to increase hydrophilicity. Take it out and ult...

Embodiment 2

[0047] 1) Cleaning of glass slides: put the slides of 10mm×15mm in deionized water for 10 minutes, ultrasonic cleaning in toluene for 10 minutes, ultrasonic cleaning in deionized water for 10 minutes, ultrasonic cleaning in acetone for 10 minutes, and ultrasonic cleaning in deionized water for 10 minutes. , sonicated in ethanol for 10 min, and ultrasonically cleaned in deionized water for 10 min. Then place the slide in SDS (10% concentration) solution and soak for 12 hours to increase the hydrophilicity. Take it out and ultrasonically clean it in deionized water 3 times, 5 min each time. The working power of the above ultrasonic machine is 100W, and the frequency is 40kHz.

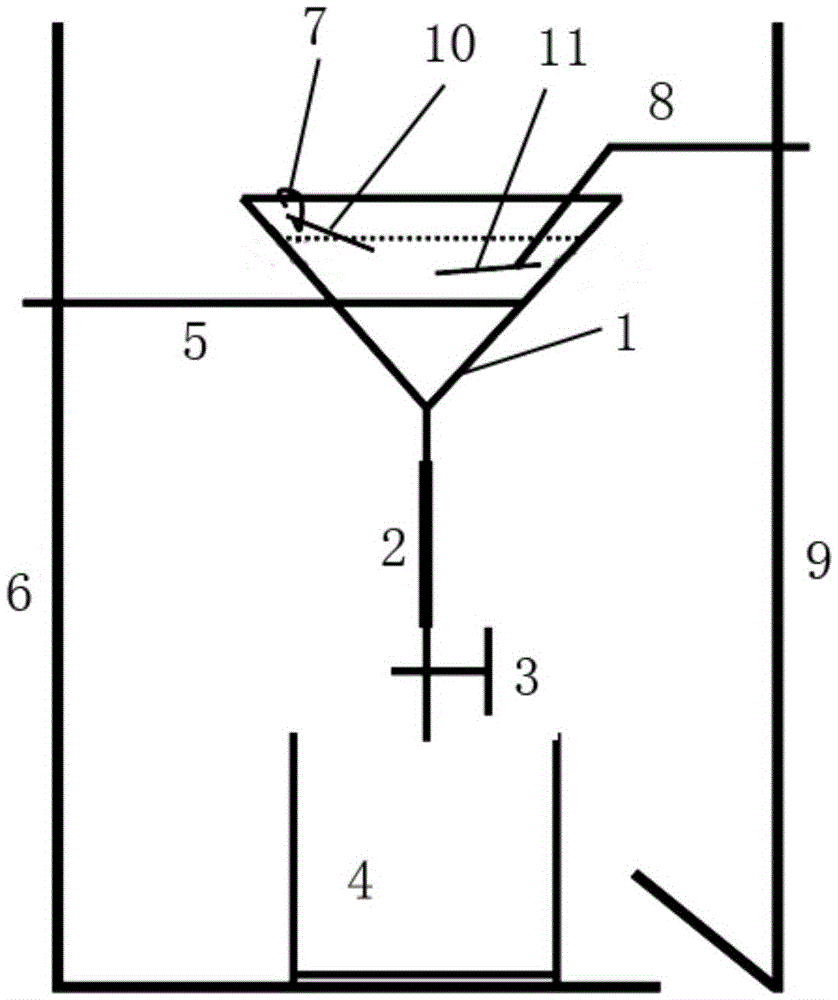

[0048] 2) Placement of the first substrate 10: place the cleaned glass slide on the first substrate holder 7 folded with copper wires, and then fix the first substrate holder 7 to the edge of the funnel mouth, so that the glass slide faces upwards, About 1 / 3 of the front surface is immersed in deionized...

Embodiment 3

[0060] 1) Cleaning of glass slides: put the slides of 10mm×15mm in deionized water for 10 minutes, ultrasonic cleaning in toluene for 10 minutes, ultrasonic cleaning in deionized water for 10 minutes, ultrasonic cleaning in acetone for 10 minutes, and ultrasonic cleaning in deionized water for 10 minutes. , sonicated in ethanol for 10 min, and ultrasonically cleaned in deionized water for 10 min. Then place the slide in SDS (10% concentration) solution and soak for 12 hours to increase the hydrophilicity. Take it out and ultrasonically clean it in deionized water 3 times, 5 min each time. The working power of the above ultrasonic machine is 100W, and the frequency is 40kHz.

[0061] 2) Placement of the first substrate 10: place the cleaned glass slide on the first substrate holder 7 folded with copper wires, and then fix the first substrate holder 7 to the edge of the funnel mouth, so that the glass slide faces upwards, About 1 / 3 of the front surface is immersed in deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com