Method and device for treating residue slurry resulting from trichlorosilane production

A technology of trichlorosilane and a treatment method, which is applied in the directions of halogenated silanes, halogenated silicon compounds, etc., can solve the problems of affecting the mass transfer, heat transfer and tray efficiency of a rectifying tower, waste of chlorosilane, and harming the rectifying tower, etc. Achieve the effect of improving the polysilicon production process, avoiding secondary pollution, and saving energy and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for treating the slurry obtained from the production of trichlorosilane, comprising the following steps:

[0030] Filter the slurry obtained from the production of trichlorosilane, the liquid substance obtained by the filtration is liquid chlorosilane, and the thick slurry is obtained by the filtration; the thick slurry is subjected to atomization treatment, and then filtered to obtain a gaseous substance, the The gaseous substances are condensed to obtain liquid chlorosilanes, and the solid substances obtained through further filtration are filter residues.

[0031] Preferably, the method for treating the slurry obtained from the production of trichlorosilane further includes a step of: adding liquid chlorosilane obtained by condensing the gaseous substance obtained through filtration into the thick slurry obtained through filtration.

[0032] Preferably, the pressure of the atomization treatment is 0.35-0.55 MPa, and the temperature o...

Embodiment 2

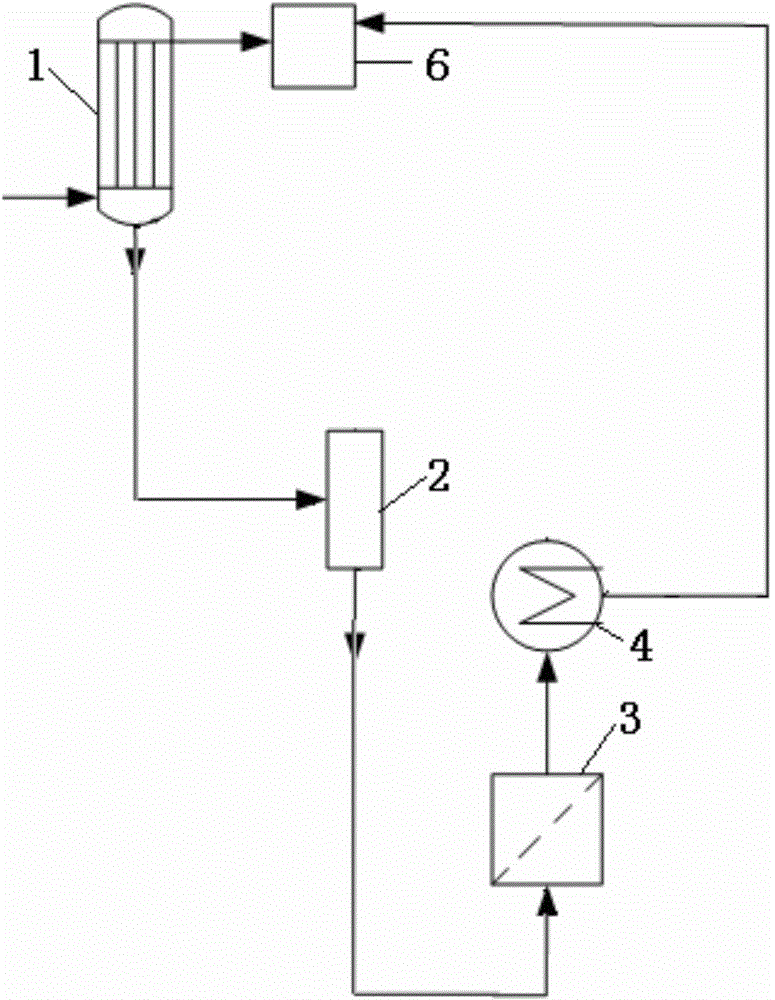

[0039] Such as figure 1 As shown, this embodiment also provides a slurry treatment device obtained from the production of trichlorosilane, including:

[0040] The filter 1 is used for filtering the slurry obtained from the production of trichlorosilane, the liquid substance obtained by the filtering is liquid chlorosilane, and the thick slurry is obtained by the filtering. Specifically in this embodiment, the liquid substance obtained by filtering with the filter 1 is liquid chlorosilane, and the liquid chlorosilane enters the subsequent chlorosilane separation and purification system 6 .

[0041] The atomizer 2 is connected with the filter 1, and the atomizer 2 is used for atomizing the thick slurry obtained through the filtration.

[0042] The bag separator 3 is connected with the atomizer 2, and the bag separator 3 is used for re-filtering, the gaseous substances are obtained through the re-filtration, and the solid substances obtained through the re-filtration are filter ...

Embodiment 3

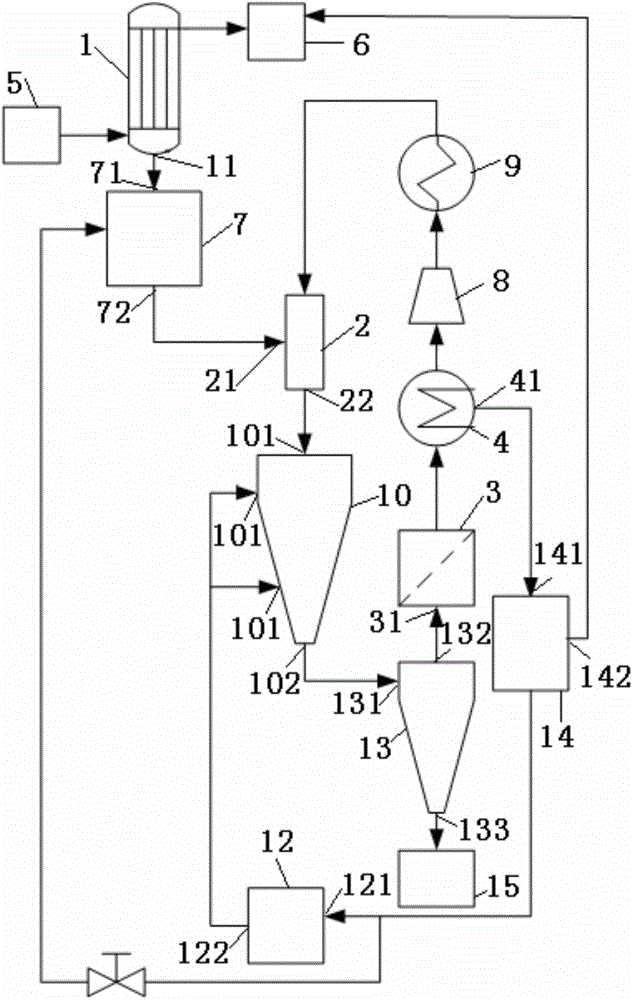

[0046] Such as figure 2 As shown, this embodiment also provides a slurry treatment device obtained from the production of trichlorosilane, including:

[0047] The slurry storage tank 5 obtained from the production of trichlorosilane is used for storing the slurry obtained from the production of trichlorosilane.

[0048] The filter 1 is connected with the slurry storage tank 5 obtained from the production of trichlorosilane, and is used for filtering the slurry obtained from the production of trichlorosilane. The liquid substance obtained by the filtration is liquid chlorosilane, and the obtained filter is obtained by the filtration. Thick slurry. The solid content concentration in the thick slurry is 50-60wt.%. The filter 1 in this embodiment is specifically a tubular filter. There is a filter cloth in the tubular filter. The filter cloth is made of special material, which is elastic and corrosion-resistant. The solid particles in the filtrate passing through the filter clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com