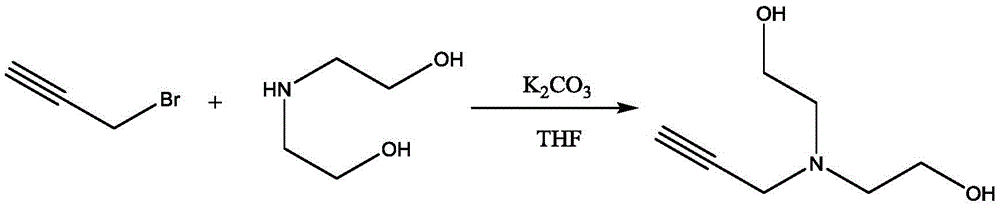

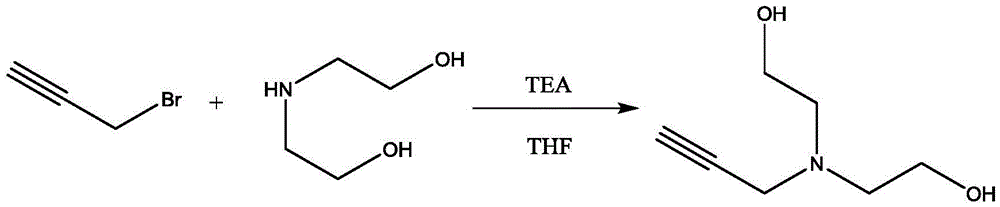

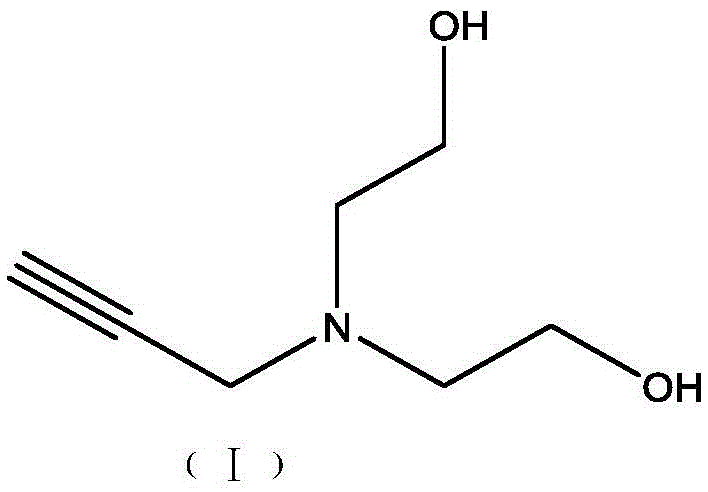

Method for synthesis and purification of bonding agent N-propargyl diethanol amine

A technology of propargyldiethanolamine and a purification method, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxyl compounds, etc., can solve problems such as non-environmental protection, complicated process, low yield, etc., and achieve an increase in yield , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The three-necked flask is equipped with mechanical stirring, a thermometer and a constant pressure dropping funnel, and is cooled by an ice-salt bath. First add 105 g of diethanolamine, 120 g of triethylamine, and 200 g of tetrahydrofuran. After cooling to 0° C., slowly add 126 g of 3-bromopropyne dropwise. The reaction is exothermic, and the temperature of the dropwise addition is controlled so that the temperature of the reaction solution does not exceed 25°C. After the addition, the reaction is continued with natural stirring for 3 hours.

[0023] After stopping the reaction, the reaction solution was filtered with suction to remove the salt generated by the reaction. The filtrate was transferred to a rotary evaporator, and tetrahydrofuran, unreacted 3-bromopropyne and triethylamine were evaporated under the conditions of a temperature of 50° C. and a vacuum of 10 mmHg. The crude product is then transferred to a vacuum distillation unit, rectifying under the conditi...

Embodiment 2

[0033] The three-necked flask is equipped with mechanical stirring, a thermometer and a constant pressure dropping funnel, and is cooled by an ice-salt bath. First add 105 g of diethanolamine, 101 g of triethylamine, and 200 g of tetrahydrofuran. After cooling to 0° C., slowly add 119 g of 3-bromopropyne dropwise. The reaction is exothermic, and the temperature of the dropwise addition is controlled so that the temperature of the reaction solution does not exceed 25°C. After the addition, the reaction is continued with natural stirring for 3 hours.

[0034] After stopping the reaction, the reaction solution was filtered with suction to remove the salt generated by the reaction. The filtrate was transferred to a rotary evaporator, and tetrahydrofuran, unreacted 3-bromopropyne and triethylamine were evaporated under the conditions of a temperature of 50° C. and a vacuum of 10 mmHg. The crude product is then transferred to a vacuum distillation unit, rectifying under the conditi...

Embodiment 3

[0036] The three-necked flask is equipped with mechanical stirring, a thermometer and a constant pressure dropping funnel, and is cooled by an ice-salt bath. First add 105 g of diethanolamine, 101 g of triethylamine, and 200 g of tetrahydrofuran. After cooling to 0° C., slowly add 119 g of 3-bromopropyne dropwise. The reaction is exothermic, and the temperature of the dropwise addition is controlled so that the temperature of the reaction solution does not exceed 25° C. After the addition, the reaction is continued with natural stirring for 2.5 hours.

[0037] After stopping the reaction, the reaction solution was filtered with suction to remove the salt generated by the reaction. The filtrate was transferred to a rotary evaporator, and tetrahydrofuran, unreacted 3-bromopropyne and triethylamine were evaporated under the conditions of a temperature of 50° C. and a vacuum of 10 mmHg. The crude product is then transferred to a vacuum distillation unit, rectified under the condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com