A kind of reactive phosphorus flame retardant and preparation method thereof

A phosphorus-based flame retardant and a reactive technology, which are applied in the field of reactive phosphorus-based flame retardants and their preparation, can solve the problem of less halogen-free flame retardants and the like, achieve improved toughness, simple preparation method, and improved easy hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

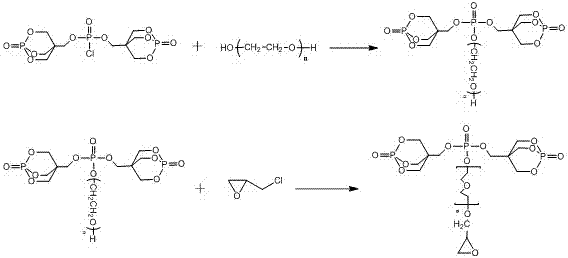

Method used

Image

Examples

Embodiment 1

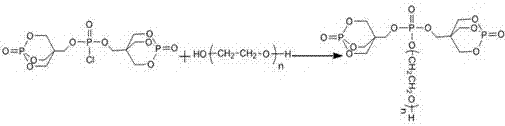

[0029] Step 1: Add 16.24 g of PEPA and 5 ml of phosphorus oxychloride to a 250 ml three-necked flask equipped with a reflux condenser, a thermometer and a magnet, then add 50 ml of solvent acetonitrile, and raise the reaction temperature until the temperature rises to 80 ℃, add the catalyst DMAP, control the reaction temperature between 80-82 ℃, after 25 hours of continuous reaction, a white solid precipitates, the product is washed with acetone or acetonitrile, and the white powder obtained after drying at 60 ℃ is the intermediate.

[0030] Step 2: Add 2.63 g of intermediates and 1.53 g of polyethylene glycol to a 100 ml three-neck flask equipped with a reflux condenser, a thermometer and a magnet, and then add 40 ml of acetonitrile as a solvent. g DMAP was added to the three-necked flask, and the temperature was controlled to react at 80-82 °C. After 25 h of reaction time, the temperature was lowered to room temperature, and a white precipitate was obtained, which was suctio...

Embodiment 2

[0033] The first step: the synthesis method of a reactive phosphorus-based flame retardant intermediate is the same as in Example 1.

[0034] Step 2: Add 2.60 g of intermediates and 1.7 g of polyethylene glycol to a 100 ml three-necked flask equipped with a reflux condenser, a thermometer and a magnet, and then add 25 ml of DMSO as a solvent. After the temperature rises to 80 °C, add Acid agent: 0.52 g pyridine; add catalyst: 0.1 g DMAP into the three-necked flask, and control the temperature at 80-82 °C for reaction. After the reaction time was 20 h, it was lowered to room temperature, and a yellow solution and a precipitate were obtained, which were suction filtered, washed, and dried to obtain a white solid powder.

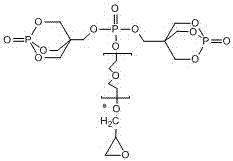

[0035] Step 3: Step 3: Add 4.31 g of polymer and 0.75 g of epichlorohydrin to a 100 ml three-neck flask equipped with a magnetic stirrer, a thermometer, and a magnet. After heating up to 90 °C, add 0.1 g of DMAP and 0.50 g pyridine was added into the three-nec...

Embodiment 3

[0037] The first step: the synthesis method of a reactive phosphorus-based flame retardant intermediate is the same as in Example 1.

[0038] Step 2: Add 2.55 g of intermediates and 1.8 g of polyethylene glycol to a 100 ml three-neck flask equipped with a reflux condenser, a thermometer and a magnet, and then add 30 ml of DMSO as a solvent. After the temperature rises to 90 °C, add Acid agent: 0.71 g triethylamine; Add catalyst: 0.1 g DMAP into the three-necked flask, control the temperature at 90-95 °C for reaction. After 25 h of reaction time, it was lowered to room temperature to obtain a yellow solution and a precipitate, which were suction filtered, washed and dried to obtain a white solid powder.

[0039] Step 3: Add 4 g of polymer and 0.8 g of epichlorohydrin to a 100 ml three-necked flask equipped with a magnetic stirrer, a thermometer, and a magnet. After heating up to 90 °C, add 0.1 g of DMAP and 0.72 g of triethylamine Add it into a three-necked flask, and control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com